Operation

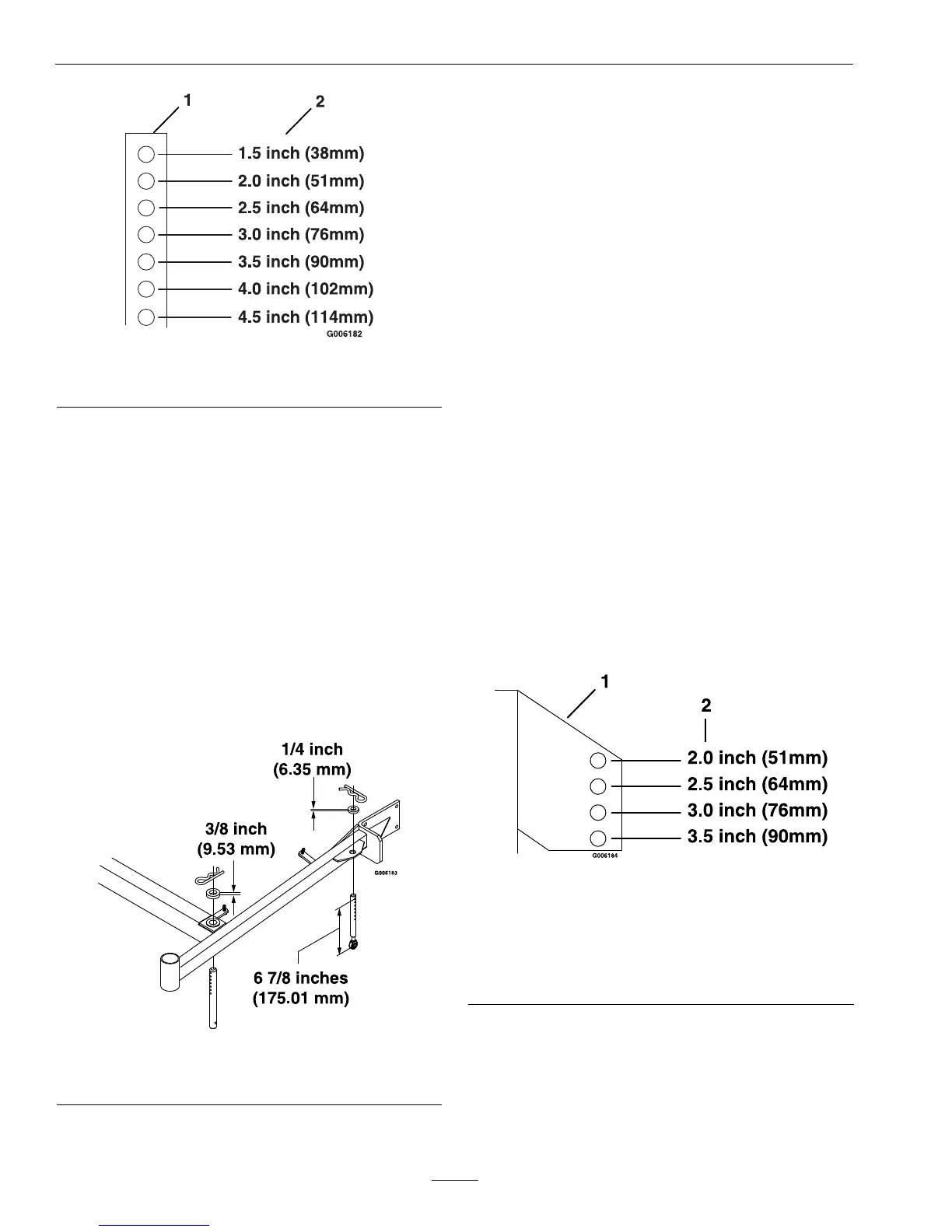

Figure6

1.Decksupportpin

2.CuttingHeight

B.ThetirepressuresaresetasdirectedinCheck

TirePressuresintheMaintenancesection.

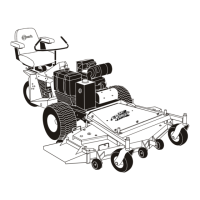

C.Thelengthofthereardecksupportlink

assembliesaverage6.89inches(approximately

67/8inches)(175.01mm)fromthecenterof

theballjointtothecenterofthefarthesthole.

See

Figure7.

Note:Allfourpinsmustequallysupportthe

weightofthedeck.Adjustmentinthelength

ofthereardecksupportassembliesmaybe

necessary.Ifonesideislongerthan6.89

inches(approximately67/8inches)(175.01

mm),thantheoppositesidemustbeshorter

bythesameamount.

Figure7

LeftHandSideShown

AdjustingtheAnti-ScalpRollers

Itisrecommendedtochangetheanti-scalproller

positionwhentheheightofcuthaschanged.

1.Stopthemachineandmovethedriveleversto

theneutrallockposition.

2.DisengagethePTO.

3.Engagetheparkbrake.

4.Stoptheengine,removethekeyandwaitforall

movingpartstostop.

5.Afteradjustingtheheightofcut,adjustthe

anti-scalprollersbyremovingthewhizlocknut

andspringdiscwasher.

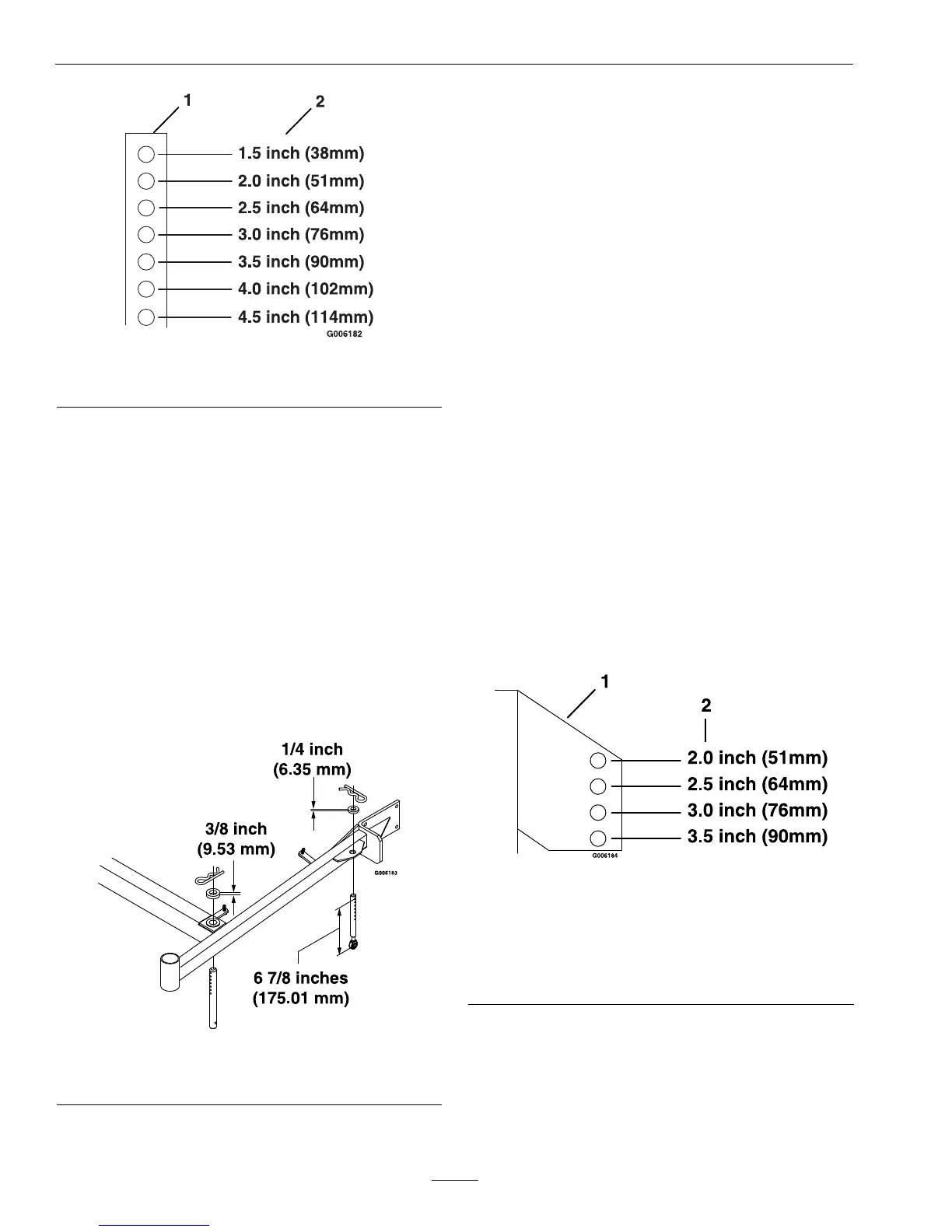

6.Adjustanti-scalprollersforNormalOperating

Conditions.Placerollersinoneofthepositions

shownin

Figure8.Rollerswillmaintain3/4

inches(19mm)clearancetothegroundto

minimizegougingandrollerwearordamage.

Note:ForMaximumDeckFlotation,place

rollersoneholepositionlower.Rollersshould

maintain1/4inch(6.35mm)clearancetoground.

DoNotadjustrollerstosupportthedeck.Be

surerollerboltsareinstalledwiththespringdisc

washerbetweenheadofthenutandmounting

bracket.

Figure8

Forcuttingheightsabove3.5inches(38mm)usethe

bottomhole.Therollerswillstillbeeffectiveagainst

scalping.

1.Anti-scalproller

mountingbracket

2.Cuttingheight

7.Torquethe3/8–16whizlocknutto30-35ft-lb

(41-47N-m)(Figure9).

8.Ifthe3/8nylocnuthasbeenremoved,reinstall

andtorqueto30–35ft-lb(41-47N-m)(Figure9).

22

Loading...

Loading...