Maintenance

InspectPTOClutchingBelt

Tension

ServiceInterval:Aftertherst2hours

Checkevery2hours

fortherst8hoursof

operation.

Every40hoursthereafter.

1.Stopengineandwaitforallmovingpartstostop.

2.EngagePTOlever.

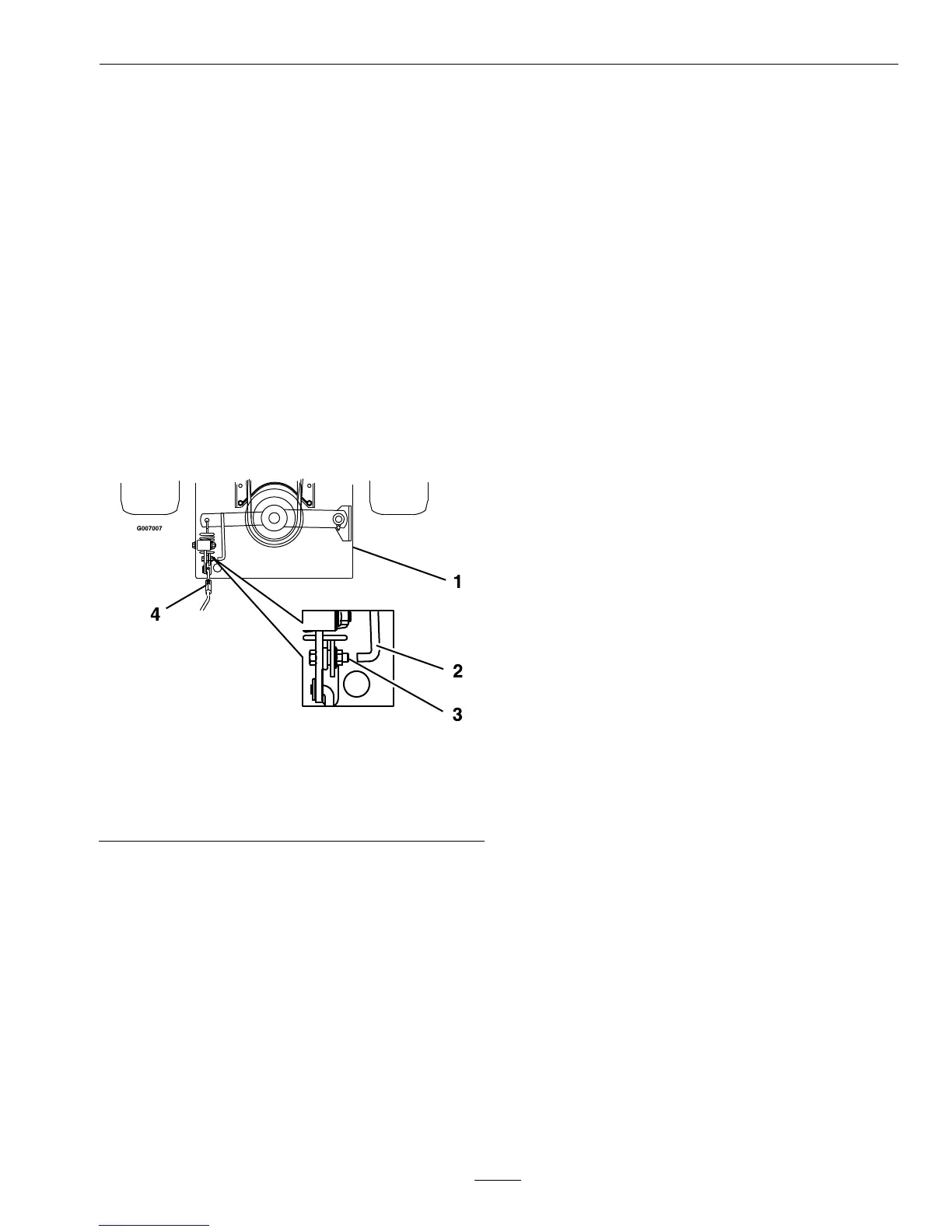

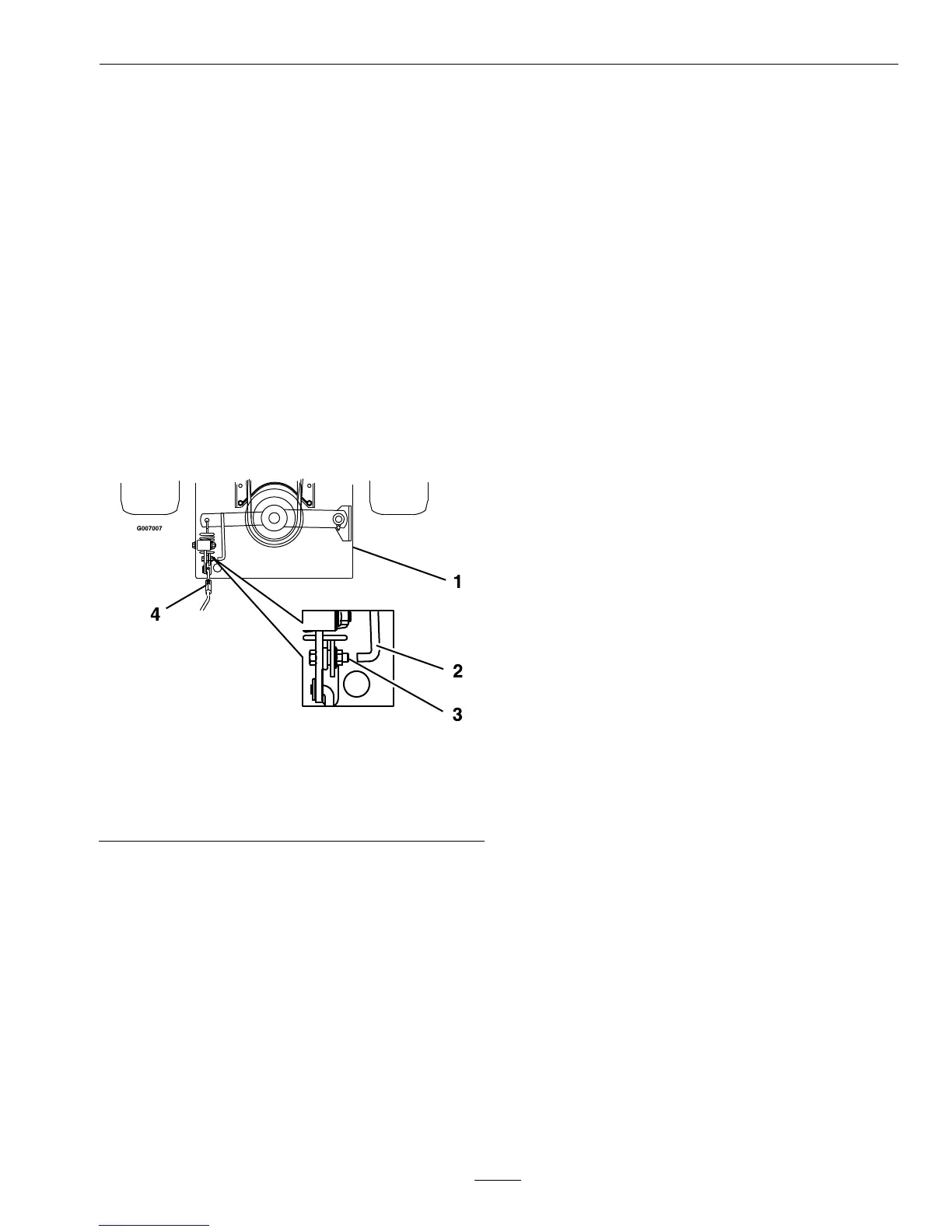

3.Lookthroughtheroundholeintheleftrear

corneroftheenginedecktoinspectblade

clutchingbelttension.Boltonbladeengagement

linkagebellcrankandindicatorarmshouldalign

within1/16inch(1.6mm)(see

Figure15).Refer

toPTOEngagementLinkageforadjustment.

Figure15

1.Enginedeck3.Alignbolttoindicator

within1/16inch(1.6

mm)

2.Indicator4.Turnbuckle

ThreadLockingAdhesives

Threadlockingadhesivessuchas“Loctite242”

or“Fel-Pro,Pro-LockNutType”areusedonthe

followingfasteners:

•Pumpsheavesetscrews.

•Squareheadsetscrewsonhydropumpcontrol

arms.

•OPCleversetscrews.

•Lowersheaveretainingboltonclutcharm.

•Shoulderboltsinendsofspeedcontrolcrank.

•Sheaveretainingboltinendofenginecrankshaft.

•Fueltankbulkheadttingthreads

Adhesivessuchas“LoctiteRC/609orRC/680”or

“Fel-ProPro-LockRetainingIorRetainingII”are

usedonthefollowing:

•OPCleverhubsandcross-shaft.

Note:Caremustbeusednottobondthe

bearing,nexttoeachOPChub,tothecross-shaft

whichcouldcausebindingoftheOPCleversand

erraticoperation.

•Fueltankstuds,wherestudsareinsertedintotank.

MobilHTSGrease(Or

Food-GradeAnti-seize)

MobilHTSgrease(orfood-gradeanti-seize)isused

inthefollowinglocations:

•Betweenthecutterhousingspindleandbearings.

•Betweenthecutterhousingspindleandsheave.

•Undertopcutterhousingbearingguard.

Copper-BasedAnti-seize

Copper-basedanti-seizeisusedinthefollowing

locations:

•OnthreadsofBladeBolts.SeeCheckMower

Bladessection.

•Betweenenginecrankshaftandpumpandblade

drivesheaves.

•Onclutcharmassemblybetweenbearingsand

shaftandbetweenlowersheaveandshaft.

•Betweenpumpshaftsandsheaves.

DielectricGrease

Dielectricgreaseisusedonallbladetypeelectrical

connectionstopreventcorrosionandlossofcontact.

Dielectricgreaseshouldnotbeappliedtosealed

connectors.

33

Loading...

Loading...