Maintenance

CheckMowerBlades

ServiceInterval:Beforeeachuseordaily

1.Stopengine,waitforallmovingpartstostop,and

removekey.Engageparkingbrake.

2.Liftdeckandsecureinraisedpositionasstatedin

theCleanGrassBuild-UpUnderDecksection.

3.Inspectbladesandsharpenorreplaceasrequired.

4.Reinstalltheblades(iftheywereremoved)inthe

followingorder:

A.Installbushingthroughbladewithbushing

angeonbottom(grass)sideofblade.

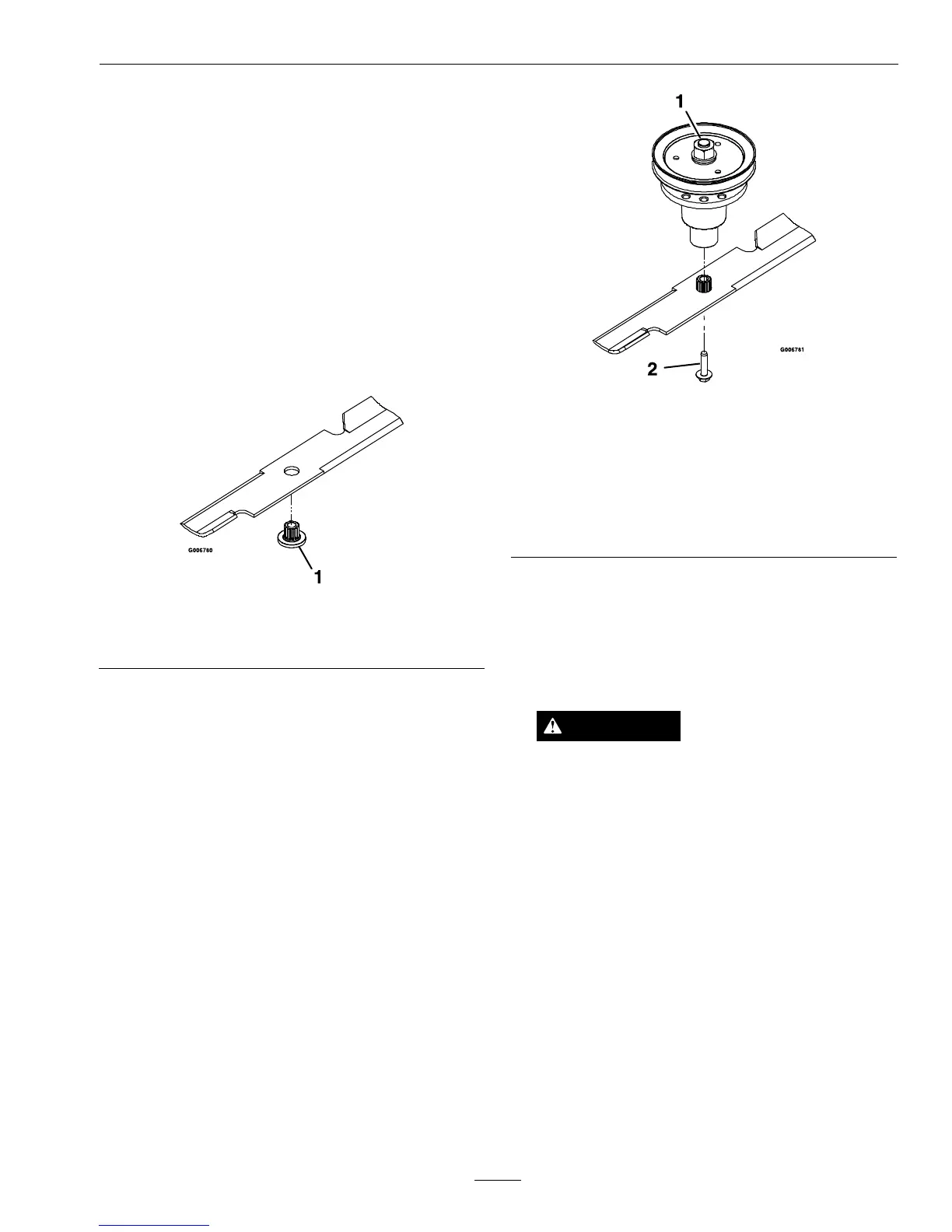

Figure11

1.Installbushinginbladepriortoinstallingbushingin

spindle.

B.Installbushing/bladeassemblyintospindle.

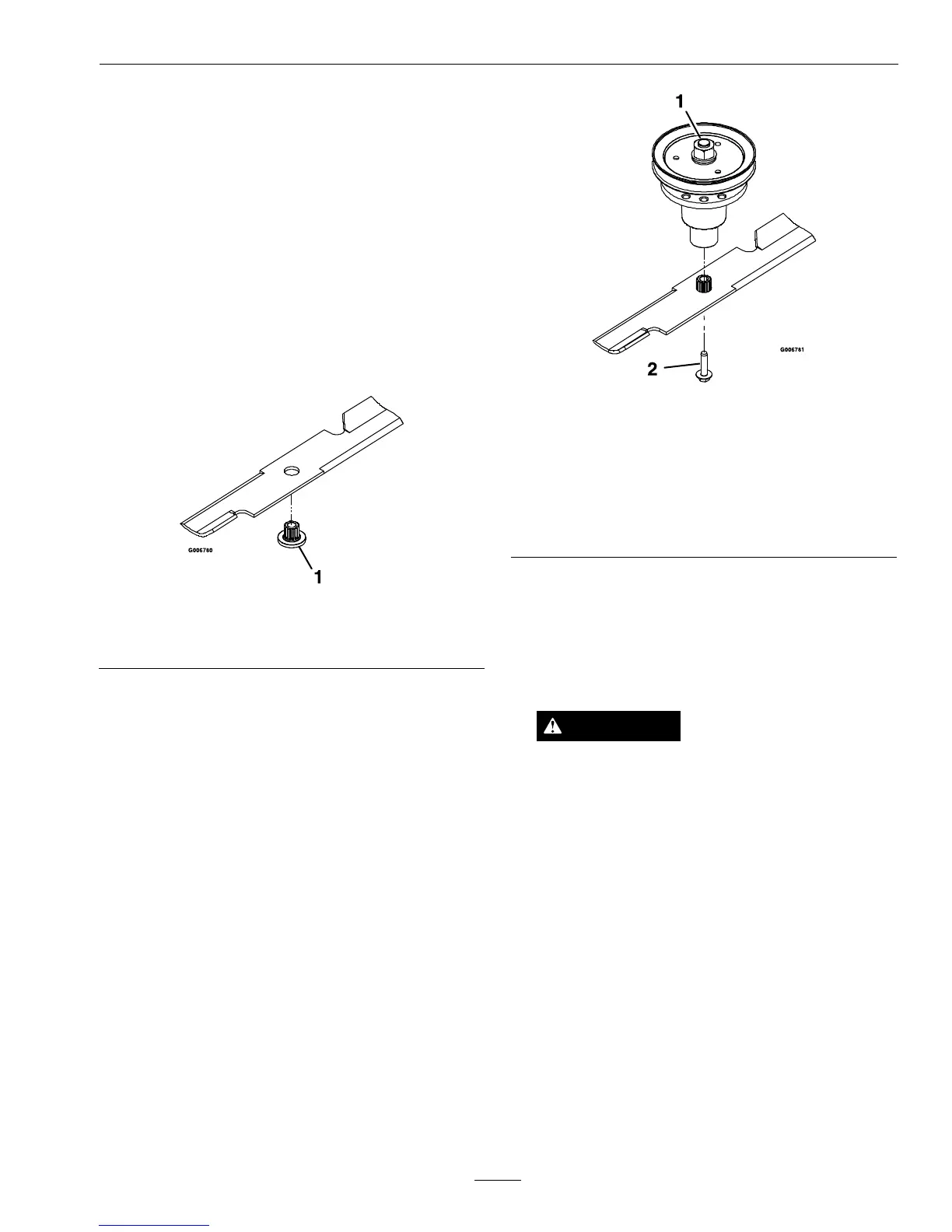

Figure12

1.Usewrenchherefor

bladeinstallation.This

nuthasbeentorquedto

140–145ft-lb(190–197

N-m)

2.Torqueto55-60ft-lb

(75-81N-m)Apply

lubricanttothreads

asneededtoprevent

seizing.Copper-based

anti-seizepreferable.

Greaseacceptable

substitute.

C.Applylubricanttothreadsofbladeboltas

neededtopreventseizing.Copper-based

anti-seizepreferable.Greaseacceptable

substitute.Installbladeboltngertight.Place

wrenchonthetopspindlenutthentorquethe

bladeboltsto55-60ft-lb(75-81N-m).

WARNING

Incorrectinstallationofthebladeor

componentsusedtoretainthebladecan

bedangerous.Failuretousealloriginal

componentsandassembledasshowncould

allowabladeorbladecomponenttobe

thrownoutfromunderthedeckresultingin

seriouspersonalinjuryordeath.

AlwaysinstalltheoriginalExmarkblades,

bladebushings,andbladeboltsasshown.

27

Loading...

Loading...