Maintenance

clockwiseabout1/4turnatatime,stopping

tomovethespeedcontrolforwardandback

toneutral.Recheckthedrivewheelrotation

toseeiffurtheradjustmentisnecessary.

4.Thespringthatkeepstensionontheknob

shouldnormallynotneedadjustment.

However,ifadjustmentisneeded,adjustto

wherelengthofspringisabout1inch(2.5cm)

betweenthewashers.Adjustspringlengthby

turningnutatfrontofspring.

•DriveLeverLinkageAdjustment:

1.Withrearofmachinestillonjackstandsand

enginerunningatfullthrottle,disengage

theparkbrakeandmovethespeedcontrol

levertothemidwayposition.Movethe

respectivedriveleverupwarduntilitreaches

theneutralpositionandengageneutrallock

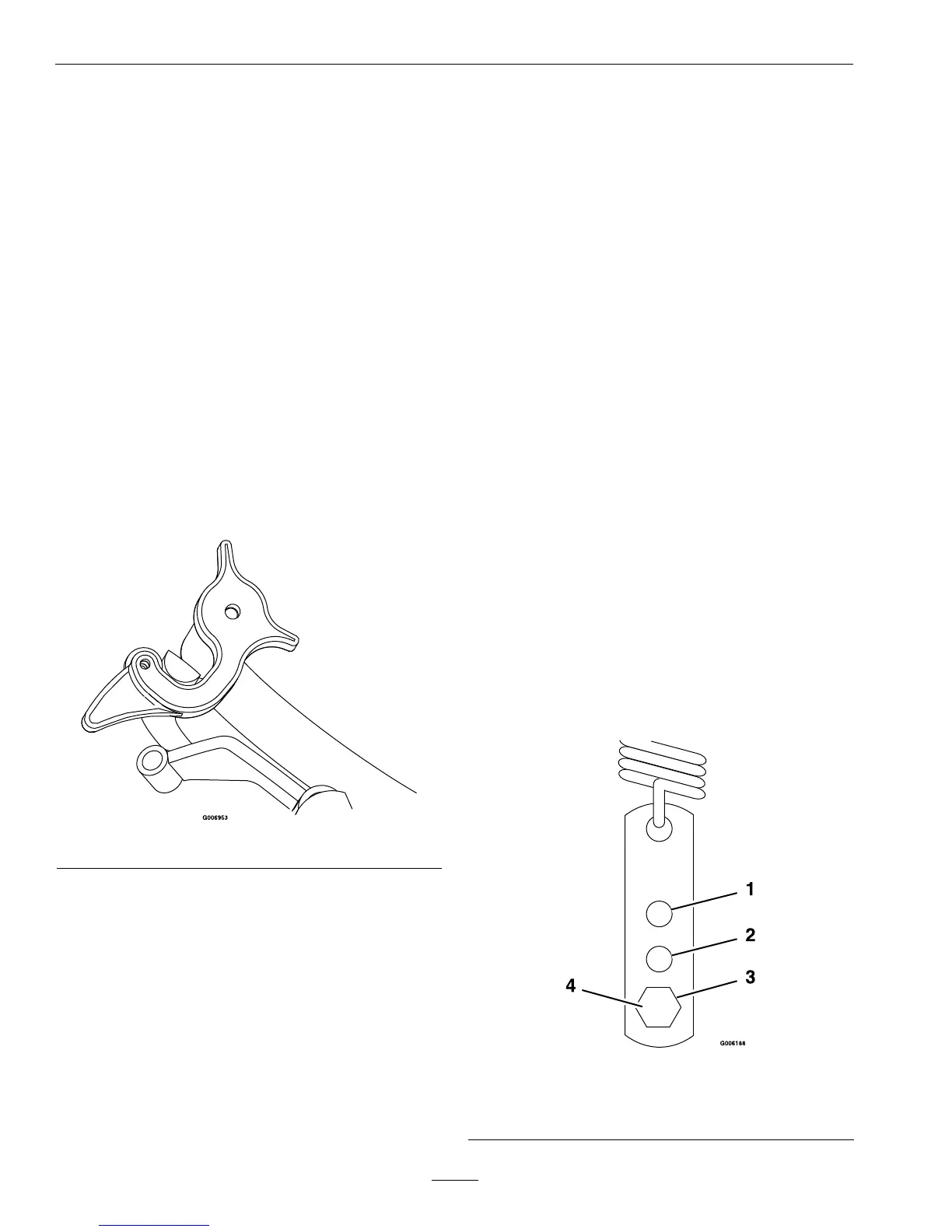

latches(

Figure19).Ifthetirerotatesineither

direction,thelengthofthedriveleverlinkwill

needtobeadjusted.

Figure19

2.Adjustthelinkagelengthbylooseningthejam

nutsatbothendsofthelinkageandrotating

thelinkageintheballjoints.Lengthenthe

linkageifthetireisturninginreverseand

shortenthelinkageifthetireiscreeping

forward.Tightenthejamnutsatbothends.

Releaseandre-engagetheneutrallocklatch

checkingthatthetirestops.Continuethis

processuntilthetireisatadeadstop.

3.Makethisadjustmentforbothsides.

4.Stopengineandwaitforallmovingparts

tostop.Raiserearofmachine,removejack

stands,andcarefullylowermachinetothe

ground.

TrackingAdjustment

1.Stopengineandwaitforallmovingpartstostop.

2.Checkthedrivetirepressuresandtire

circumferencesasstatedinChecktheTire

PressuressectioninMaintenance.

3.Runtheunitandobservethetrackingonalevel,

smooth,hardsurfacesuchasconcreteorasphalt.

4.Iftheunittrackstoonesideortheother,turnthe

quicktrackknob.Turntheknobrightto“steer”

right,turntheknobleftto“steer”left.

HydroPumpSpringTension

Setting

1.Formediumorheavydutydriveconditionssuch

asoperationwithasulkyonsteepslopes,ahigher

springforcemayberequiredonthehydropump

controlarmstopreventthedrivesystemfrom

stalling.

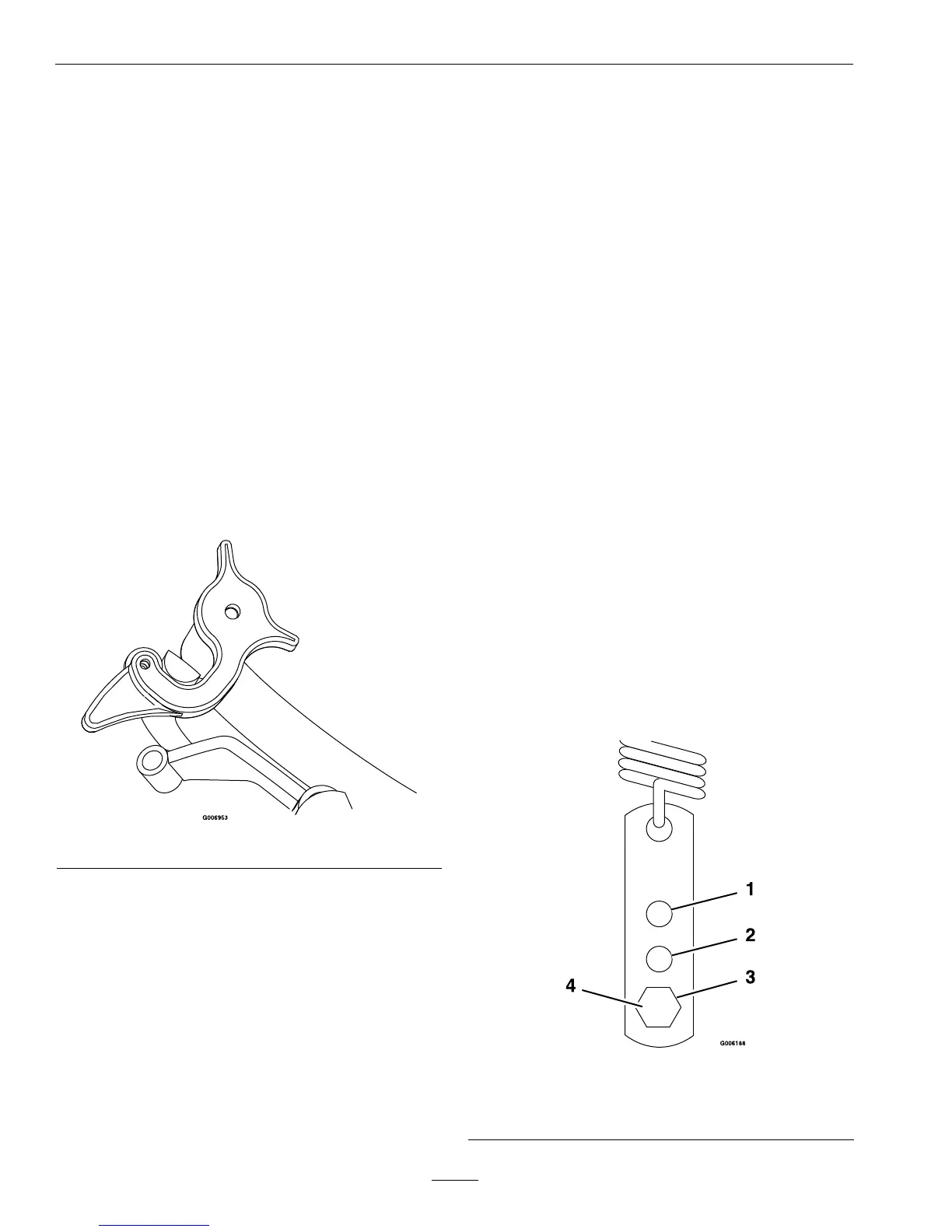

2.Foraheavierdrivesetting,relocatethespring

anchorlinkasshowninFigure13.Thespring

anchorlinksarelocatedundertheenginedeckon

theleftandrighthandsides.

Note:In“medium”or“heavyduty”positions,

thedriveleverforcesattheupperhandlewillalso

beincreased.

Figure20

1.Heavyduty

3.Standard

2.Mediumduty4.Retainingbolt

36

Loading...

Loading...