SAFETY DEVICES

5

ENGLISH

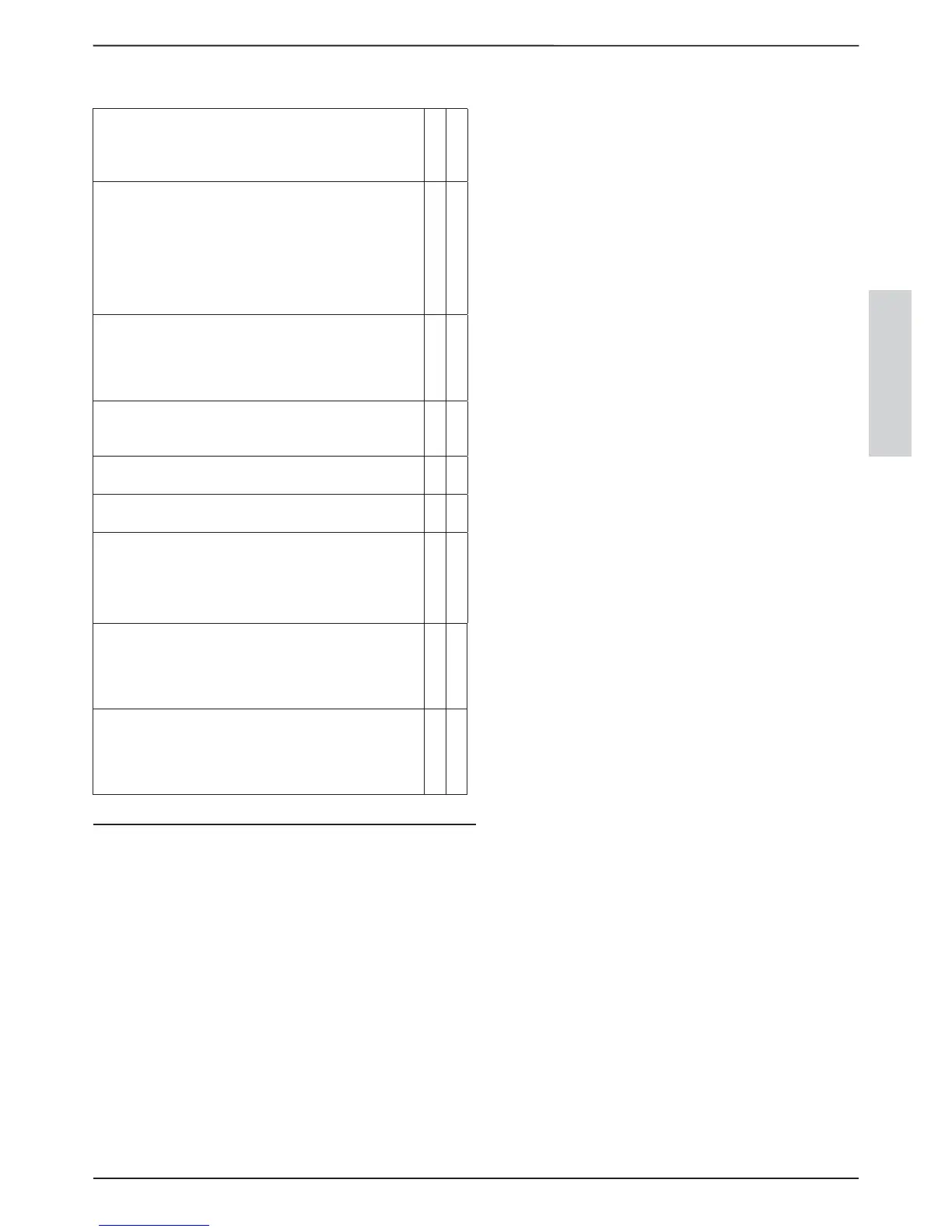

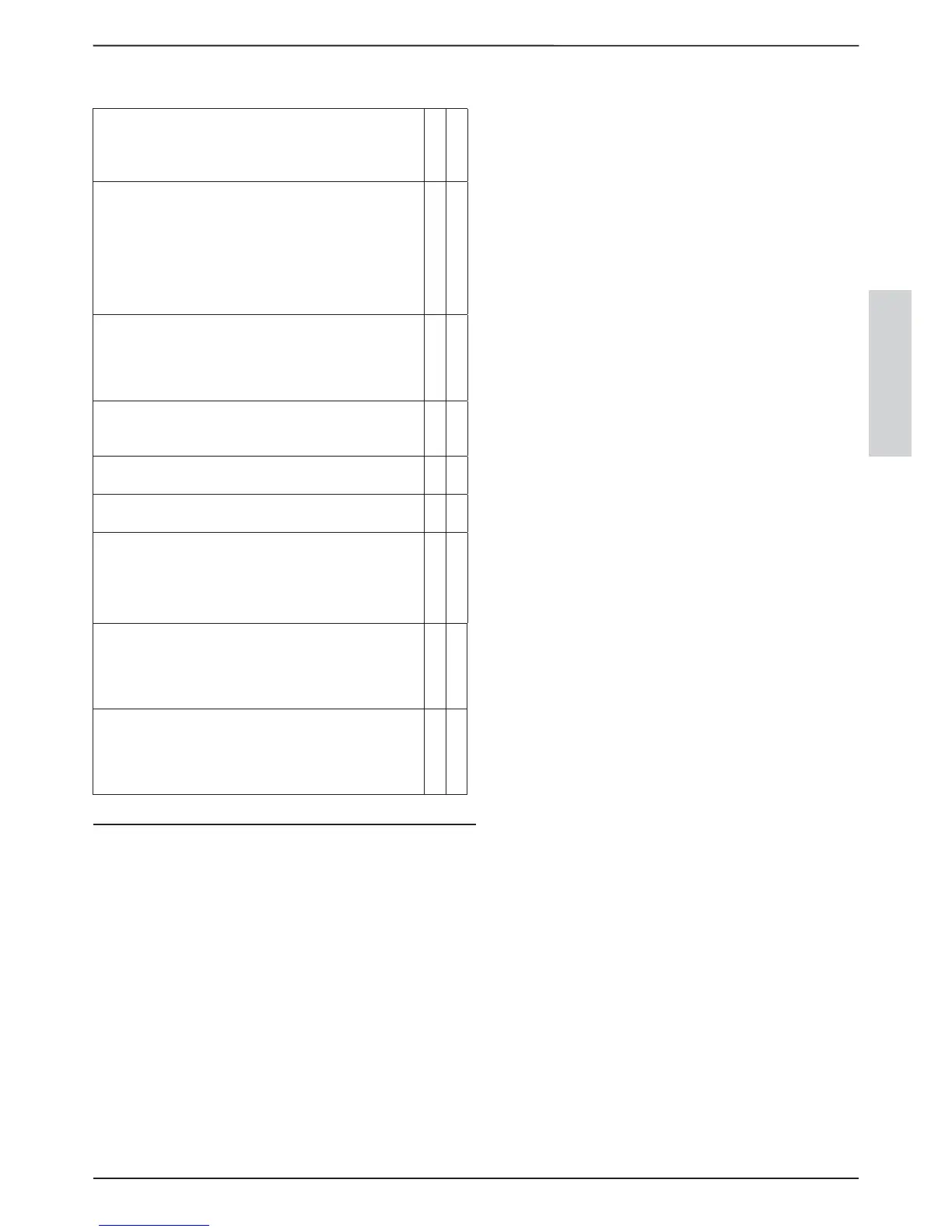

SAFETY DEVICES3.

SAFETY DEVICES

Key: * = present,

- = not present

STOVES

INSERTS

Circuit board: intervenes directly by sending the product

into alarm conditions until complete cooling, in the case

of: breakage of ue gas motor, pellet feed motor breakage,

black out (if more than 10 seconds), no ignition

**

Upper door micro switch (combustion chamber): if the

combustion chamber is opened, the pellet feed motor

functioning is blocked (*in some models)

*_

Insert blocking micro switch: if the end run micro switch

warns that the insert is not blocked, electric energy does

not pass to power it

-*

Flow sensor: in the case of inadequate depression, it

takes the machine to alarm conditions

**

F2.5 A 250V fuse (stoves): protects the machine from

violent current drops

**

85°C calibrated mechanical bulb with manual rearm:

intervenes by blocking fuel feed whenever the pellet tank

t° reaches the limit of 85°C. Rearm must be performed

by quali ed sta and/or the manufacturer's technical

after-sales assistance.

**

Pellet feed-box temperature control probe: if the tank

should overheat, the machine modulates automatically in

order to return to normal temperature values (* in some

models)

**

Mechanical air pressure switch: blocks the pellets in

the event of insu cient depression (in the models where

envisioned)

**

INSTALLATION4.

The installation must be in compliance with:

UNI 10683 (2005) heat generators fed with wood and

other solid fuels: installation.

The chimneys must be in compliance with:

UNI 9731 (1990) chimneys: classi cation based on thermal

resistance.

EN 13384-1 (2006) Thermal and uid dynamic calculation

methods.

UNI 7129 point 4.3.3 Fire Department dispositions, local rules

and prescriptions.

UNI 1443 (2005) chimneys: general requisites.

UNI 1457 (2004) chimneys: clay/ceramic ue liners.

GLOSSARY

CLOSED HEARTH APPLIANCE

Heat generator which opening is only allowed through the loading

of the fuel during use.

BIOMASS

Biological material, excluding the material incorporated in

geological formations and transformed into fossils.

BIOFUEL

Fuel produced directly or indirectly by biomass.

CHIMNEY

Vertical pipe with the aim of collecting and expelling the fuel

products coming from only one appliance, at a convenient height

from the ground.

SMOKE CHANNEL OR FITTING

Pipe or connecting element between heat generator appliance

and chimney to evacuate fuel products.

INSULATION

Group of set-ups and materials used to prevent the transmission

of heat through a wall that separates rooms with di erent

temperatures.

CHIMNEY CAP

Device positioned at chimney peak to ease the dispersion of

combustion products into the atmosphere.

CONDENSATE

Liquid products which form when the fuel gas temperature is lower

or equal to the water dew point.

HEAT GENERATORS

Appliance which allows to produce thermal energy (heat) through

the rapid transformation, through combustion, of the chemical

energy of the same fuel.

GATE VALVE

Mechanism for modifying the combustion gas dynamic

resistance.

COMBUSTION PRODUCT EVACUATION SYSTEMS

Flue gas exhaust system independent from the appliance

constituted by a tting or smoke channel, chimney or individual

ue and chimney cap.

FORCED DRAUGHT

Air circulation by means of the fan activated by electric motor.

NATURAL DRAUGHT

Draught which determines in a chimney/ ue due to e ect of

the volume mass di erence existing between smoke (hot) and

surrounding atmosphere air, without any mechanical intake aid

installed inside it or at its peak.

RADIATION AREA

Area immediately near the hearth in which the heat caused by

combustion is di used, where there must be no combustion

materials .

REFLUX AREA

Area where leaking of the fuel products is veri ed, from the

Loading...

Loading...