3. Printer Operation

3.1. Commission

Printer needs to be filled with ink and exhaust air before use.

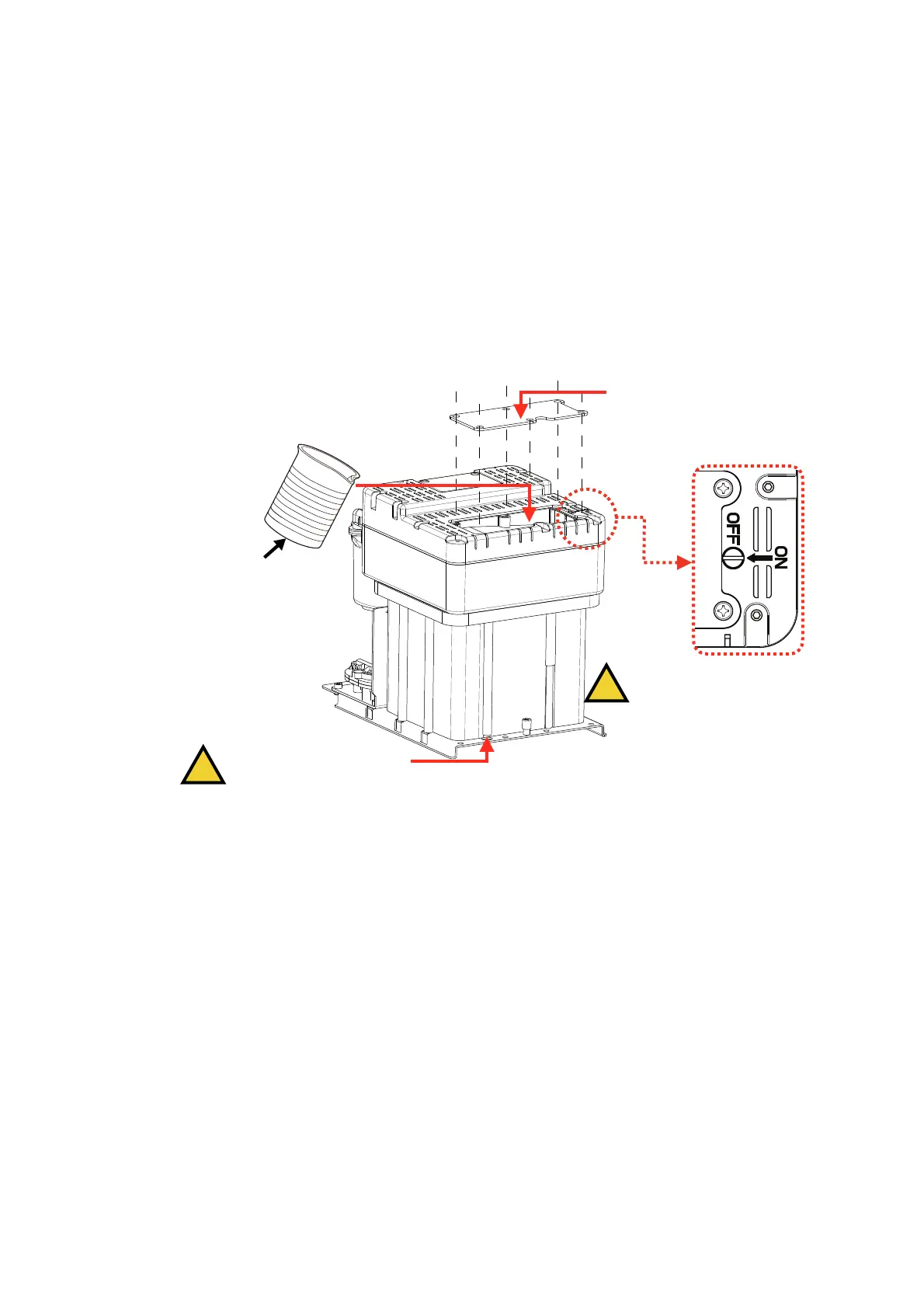

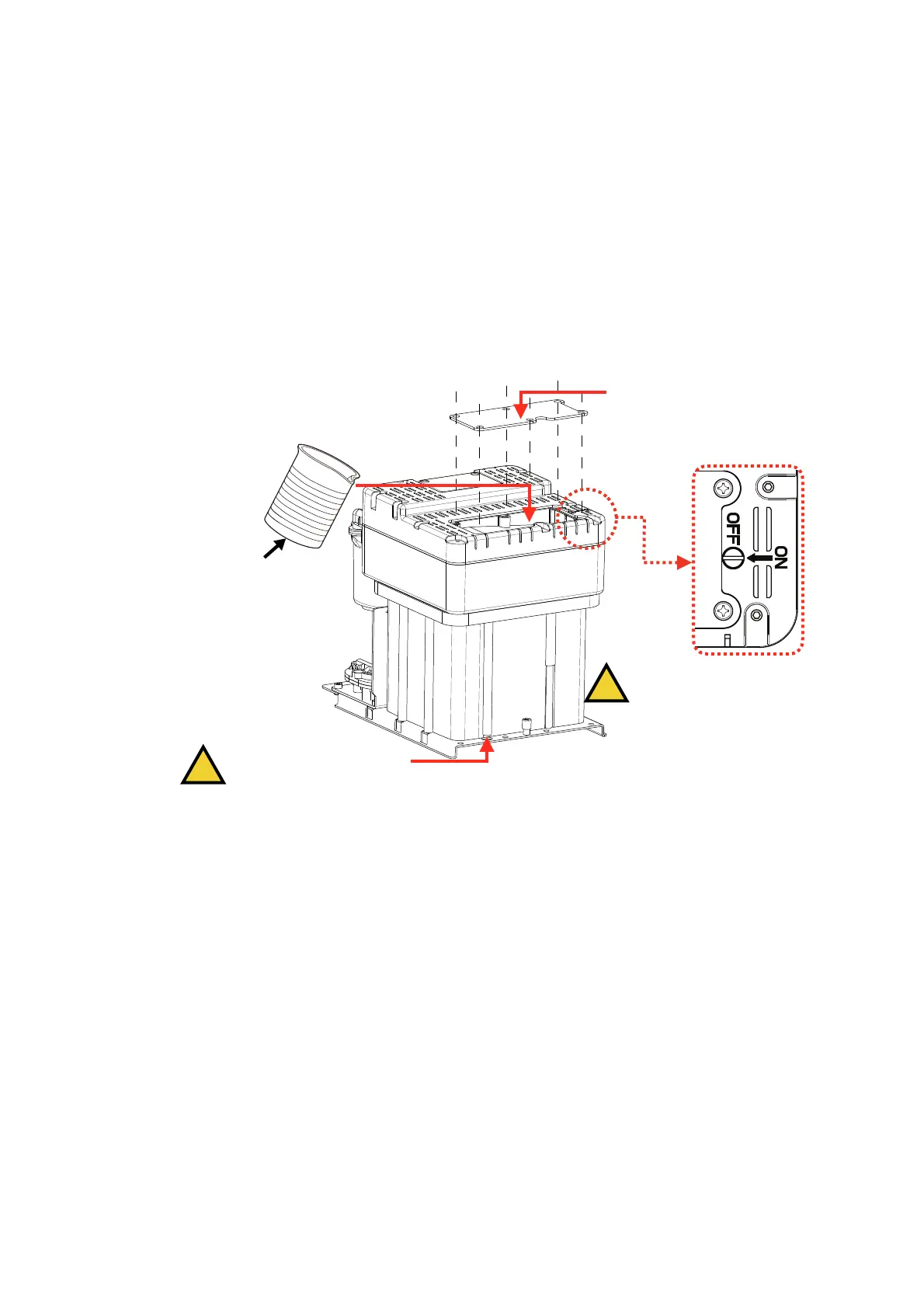

1. Open the lower cabin door, pull out the ink system, and fill 750ml of ink

into the mixer tank with a beaker in the order of A. B.* C. D., as shown in

figure:

2. During the ink filling process, check the diagnostic screen. The low level

of the mixer tank should be changed to “ ON ” to reach the minimum ink

level required by the printer (approximately 210ml of ink at this time), and

continue to fill the remaining ink in the bottle.

3. According to the label, fill the correct ink and make-up to the correct tank,

push the ink system into the cabin and close the lower cabin door .

4. After the manual ink filling operation is completed, confirm that the levels

of the mixer tank, ink tank and solvent tank both are normal, and then

the air exhaust air operation can be started.

5. Exhaust Air, please follow the steps as below:

* During normal use of the printer, the exhaust vent plug A needs to be removed, and the exhaust

air switch B needs to be opened , otherwise it will cause printer failure.

Loading...

Loading...