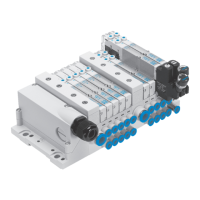

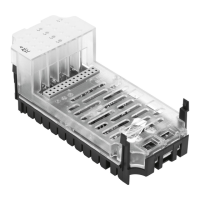

What to do if the proportional pressure regulator of my Festo Terminal Block does not react?

- XxparrishJul 28, 2025

If the proportional pressure regulator of your Festo Terminal Block isn't reacting, first check the 24 V DC supply voltage. If the POWER LED isn't lit, this could be the issue. Also, make sure the supply pressure is switched on. If the setpoint value is reached, try modifying it. If none of these steps work, the regulator may be defective and should be sent to Festo for repairs.