3. Installation

3−13

Festo P.BE−MPA−EN en 0910d

Note

· Use closed−loop regulated external pilot air (3 ... 8 bar).

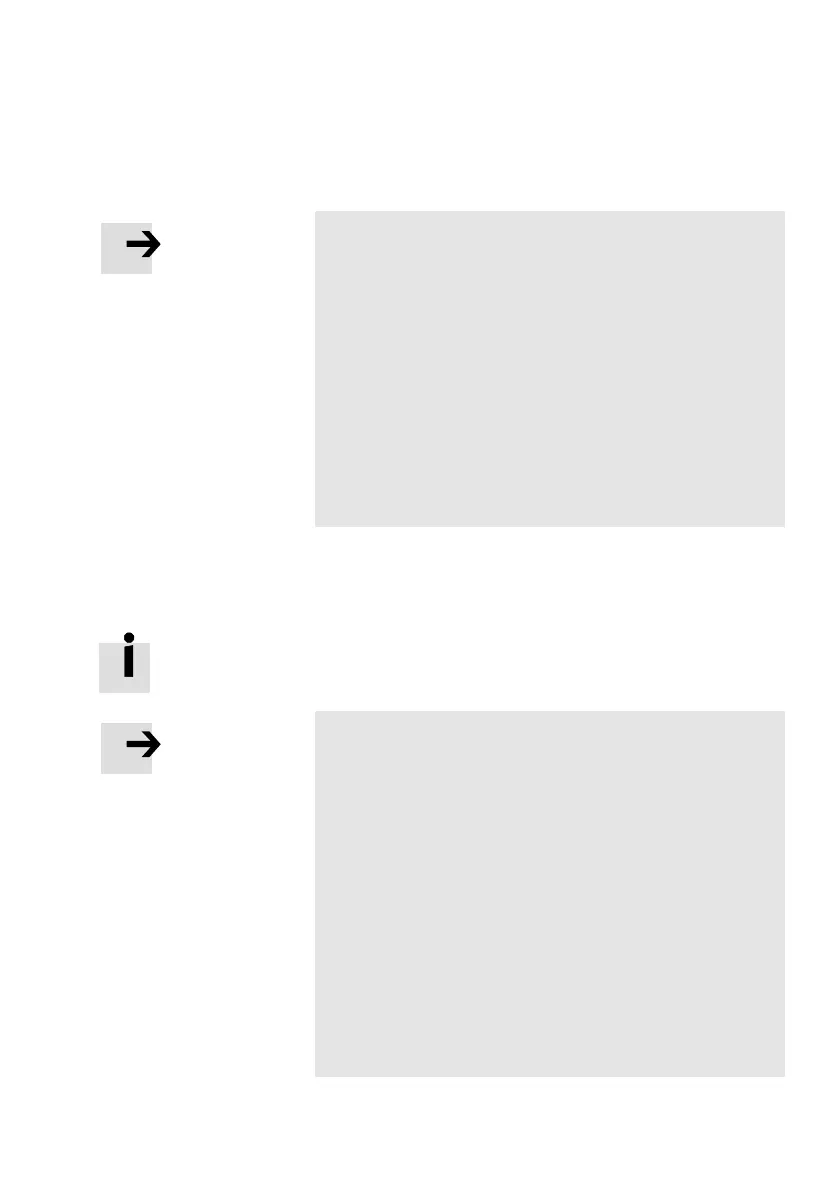

Reliable faultless operation of the MPA−S valve terminal

is then possible, e.g. even with fluctuating operating

pressure.

· The external pilot air is supplied centrally via the pilot

port (12/14) on the pneumatic interface or the multiple

connector plate. This is the case even if the MPA−S

valveterminal is operated with different pressure zones.

· Set the external pilot air supply to correspond to the

operating pressure at which these valves are operated

(seediagrams in appendix A, Fig.A/1, Fig.A/2 and

Fig.A/3).

3.4.2 MPA−S valve terminal with pressure zone separation

Basic information on pressure zone separation is provided in

chapter 1, section Pressure zone separation".

Note

· Operate the valves with ident. code I (2 x 2/2−way valve)

in a separate pressure zone with separate exhaust

channnel (5) if the MPA−S valve terminal is also fitted

with other valves.

Note the following in the case of the MPA−S valve terminals

which are operated with internal pilot air and which have

several pressure zones:

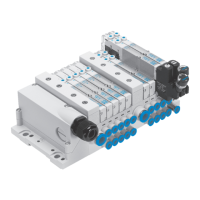

· The internal pilot air supply is branched centrally from

the supply connection (1) of the pneumatic interface or

from the multiple connector plate (see Fig.3/3).

· The pressure zone, which is supplied via the supply

connection(1) of the pneumatic interface or the multiple

connector plate, must be operated at a pressure

between 3 ... 8 bar.

Loading...

Loading...