33

SUBSYSTEM 2: HYDRAULIC SYSTEM

Hydraulic power for the Bark Blower is generated by a fixed-displacement hydraulic pump that is

driven off the engine auxiliary drive. The pump receives hydraulic fluid from the 15-gallon (57 L)

reservoir through a service ball valve and suction hose. It is then delivered to the solenoid control

valves for both the rotary air valve and drag chain conveyor / feed roll circuits. The pressure

driving the two individual hydraulic circuits can be monitored by utilizing the gauges provided on

the drag chain conveyor and rotary air valve manifolds.

The hydraulic oil should be replaced per the lubrication schedule or if the oil becomes milky or

gives off a burnt odor. The hydraulic oil filter must be replaced on schedule with a 5 absolute

micron filter.

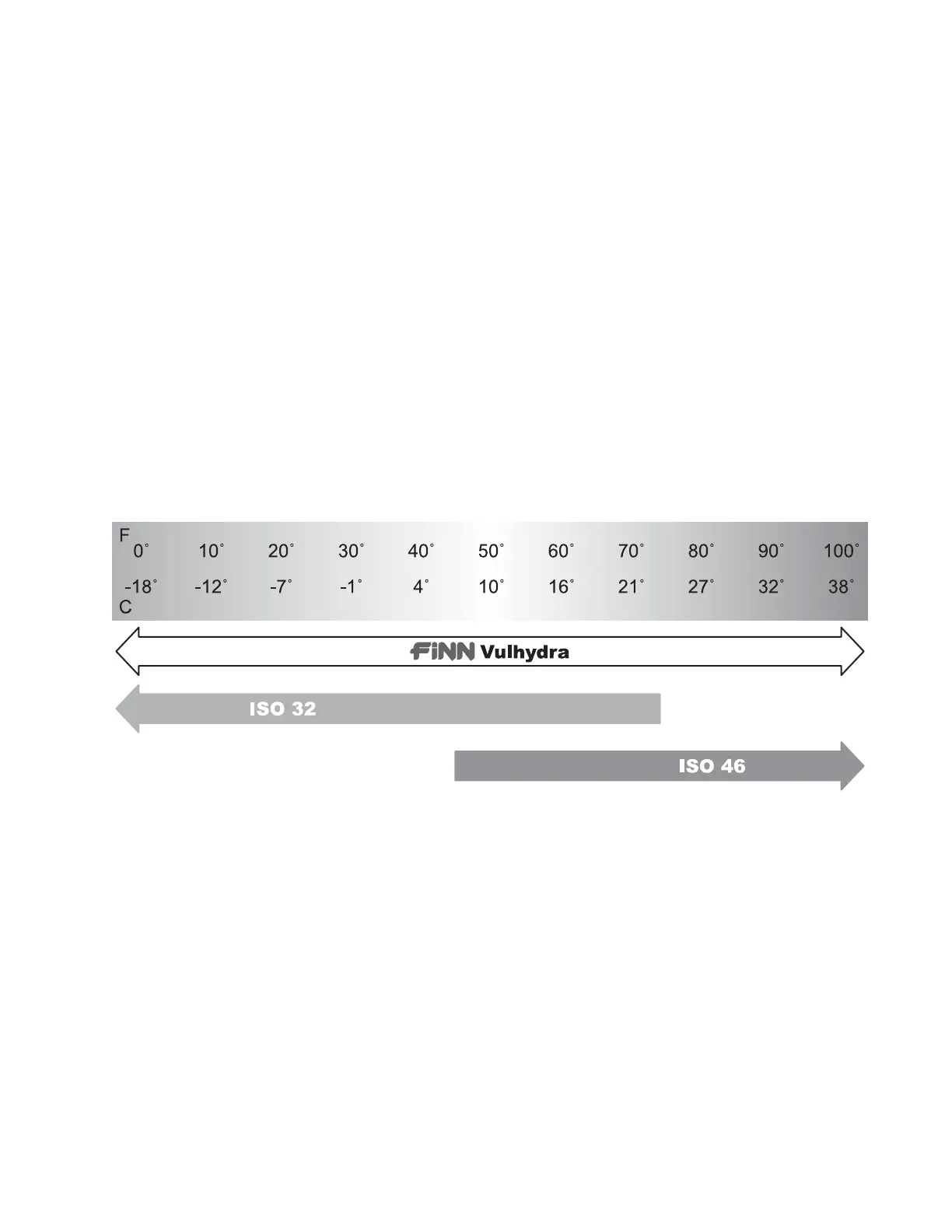

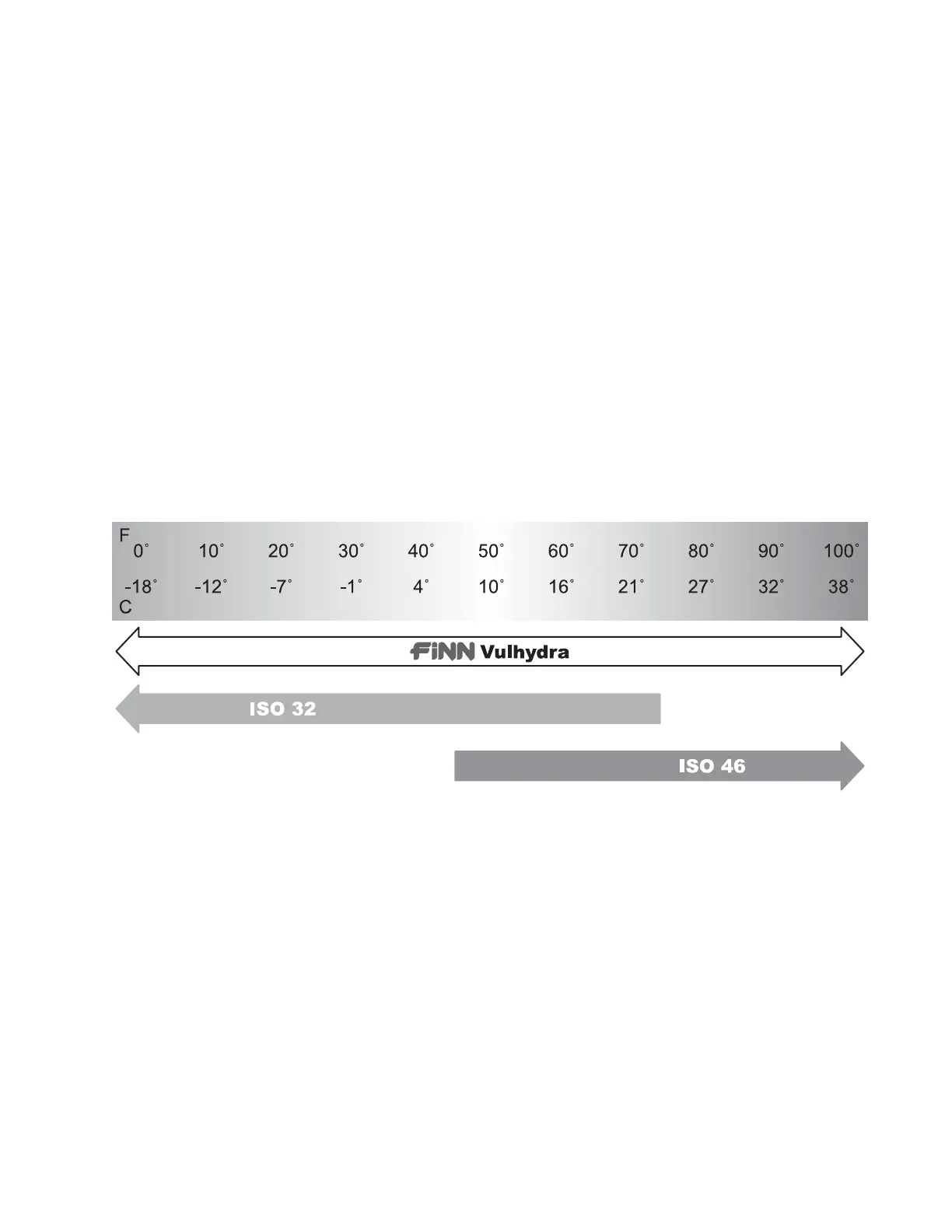

At time of manufacture, this unit contains Finn Vulhydra hydraulic oil. The chart below illustrates

the operating temperature range of the Finn Vulhydra hydraulic oil as well as the closest ISO

equivalents.

NOTE: When changing the hydraulic fi lter, use 5 micron or better filter element.

NOTE: The Finn Vulhydra hydraulic oil may be substituted for either of the two ISO

oils listed below. Please use the temperature chart to determine what oil

works best in your situation.

A. ROTARY AIR VALVE/FEED ROLL

The fixed displacement pump delivers hydraulic oil to a flow divider manifold and from the flow

divider manifold, 66% of the oil is routed to the rotary air valve motor through a solenoid valve.

The solenoid valve is an open-center spool valve with built in relief set at 2650 psi (18 271 kPa).

The spool in the valve is spring-centered and is moved by actuating a 12 VDC solenoid on either

end of the spool.

Applying a 12 VDC signal to the solenoid causes the spool cartridge to shift directions. This

action causes the high pressure hydraulic oil to be directed to the work port of the valve, causing

the rotary air valve to move either in the forward or reverse direction.

NOTE: Spool movement can be checked manually by pressing the override button

located in the center of the recessed area on the solenoid clamping nut.

Loading...

Loading...