48

than halfway through. Swivel flanges are available if desired (#60-302 for UV1A, UV2 Scan-

ners, #60-1664-3 for 45UV5). The sight pipe must permit an unobstructed view of the pilot and/

or main flame, and both pilot and main flames must completely cover the scanner field of view.

5. Smoke or unburned combustion gases absorb ultraviolet energy. On installations with negative

pressure combustion chambers, a small hole drilled in the UV1A, UV2 sight pipe will assist in

keeping the pipe clean and free from smoke. For positive pressure furnaces, provide clean air to

pressurize the sight pipe, if necessary.

6. Two UV1A or UV2 Scanners may be installed on the burner if it is necessary to view two areas

to obtain reliable detection of the flame. They should be wired in parallel. Only one repetitive

self- checking 45UV5 Scanner may be installed on a burner.

To increase scanner sensitivity with UV1A, UV2 Scanners, a quartz lens permits location of the

scanner at twice the normal distance. Use 1/2" x 1 1/2" pipe nipple between UV1A Scanner and the

coupling. Use 3/8" pipe nipple and a 1/2" x 3/8" bushing on UV2 installations.

7. Request the assistance of any Fireye field office for recommendations of a proper scanner instal-

lation on a non-standard application.

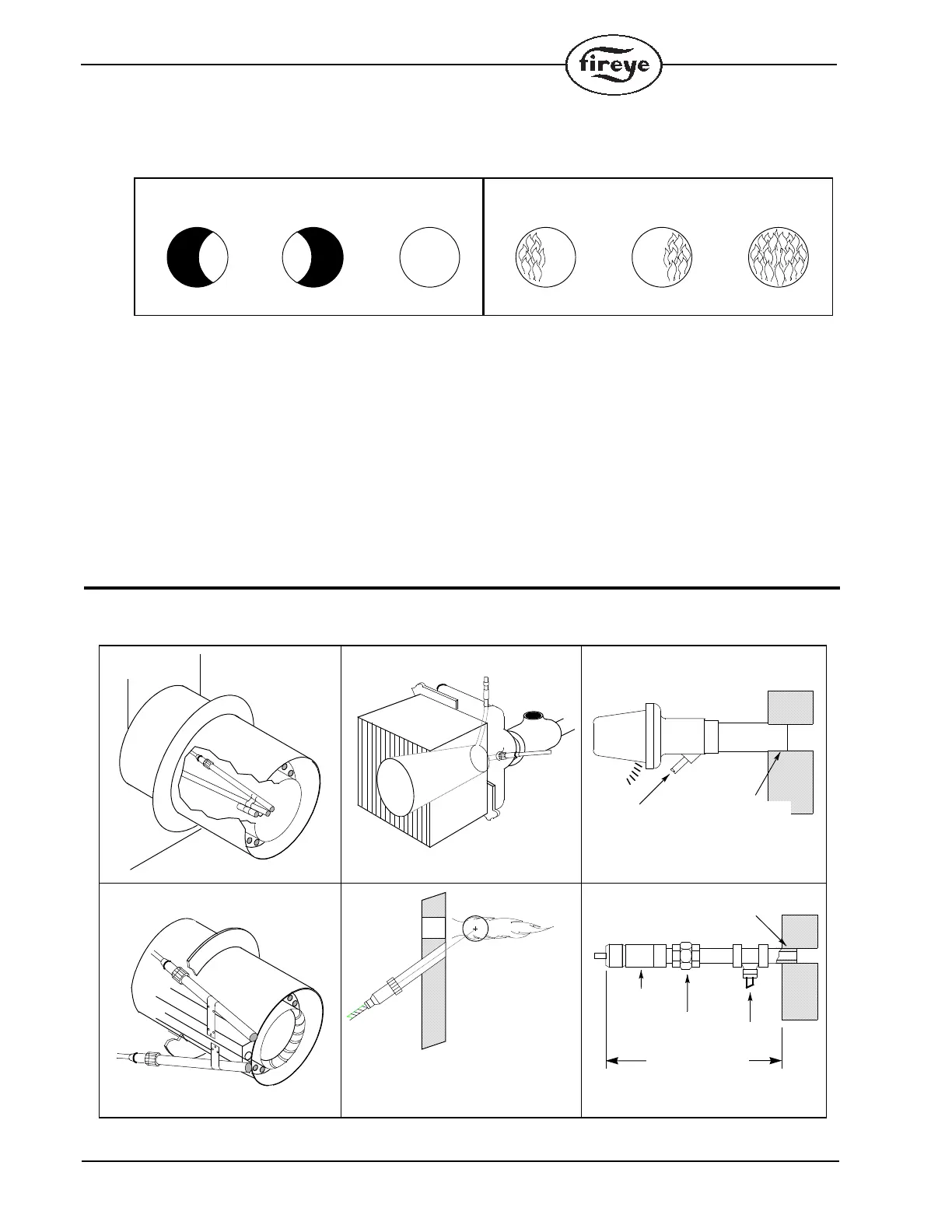

TYPICAL SCANNER INSTALLATIONS

SCANNER MUST HAVE UNOBSTRUCTED

VIEW OF FLAME

NOT THIS NOT THIS BUT THIS

FLAME MUST COMPLETELY COVER

SIGHT OPENING

NOT THIS

NOT THIS BUT THIS

The maximum UV signal

from a flame is found in

the first one-third of the

visible flame taken from

the point where the flame

begins. The scanner sight

pipe should be aimed at

this area.

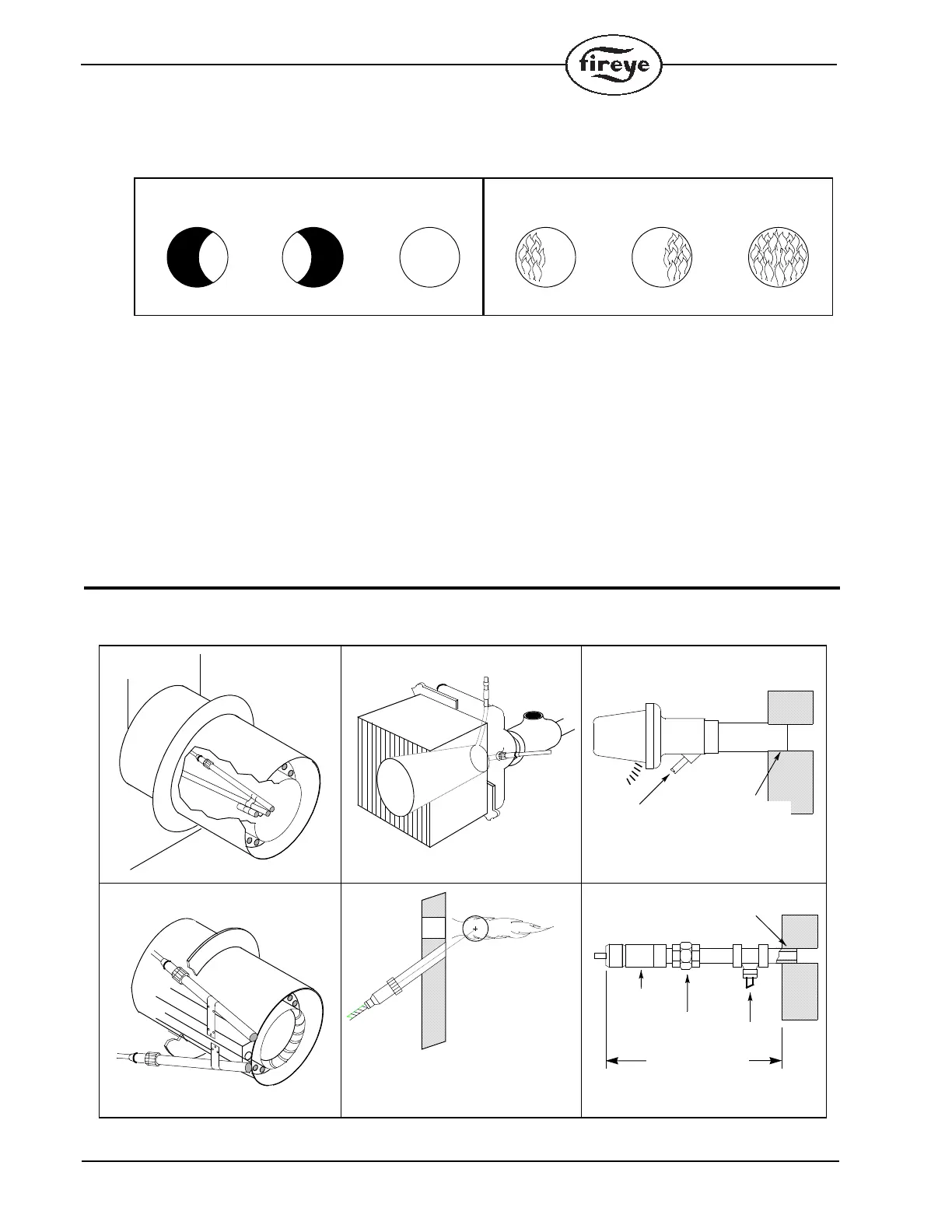

DO NOT EXTEND

MORE THAN

HALF-WAY INTO

REFRACTORY

SCANNER

FORCED

CLEAN AIR

(FROM DISCHARGE

OF FAN)

METHODS OF COOLING SCANNER

INSULATING

TUBING

SEALING

UNION

FORCED

AIR

EXTEND SIGHTING TUBE

6”(152.4) OR 8”(203.2)

DO NOT EXTEND MORE THAN

HALF-WAY INTO REFRACTORY

Loading...

Loading...