Page 27

Troubleshooting

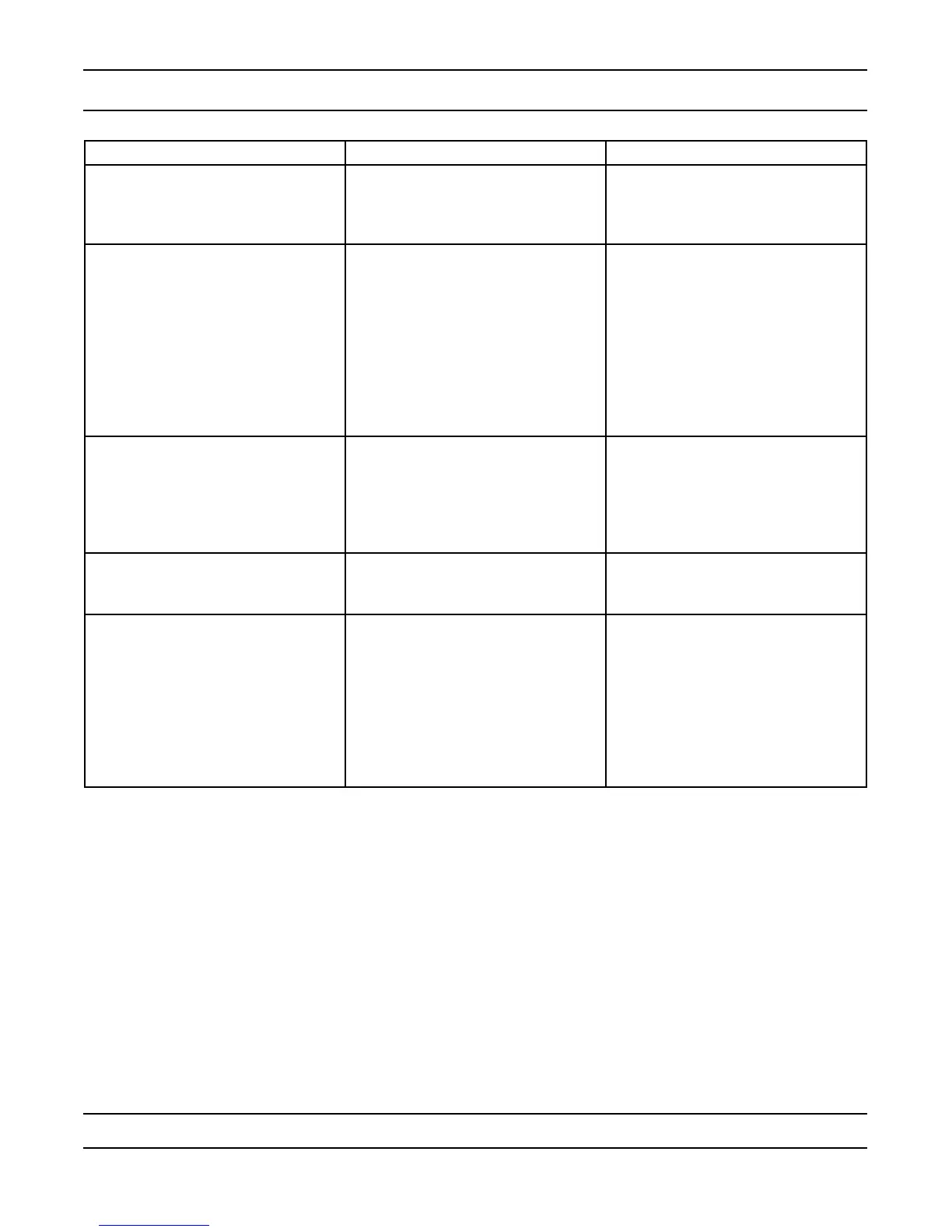

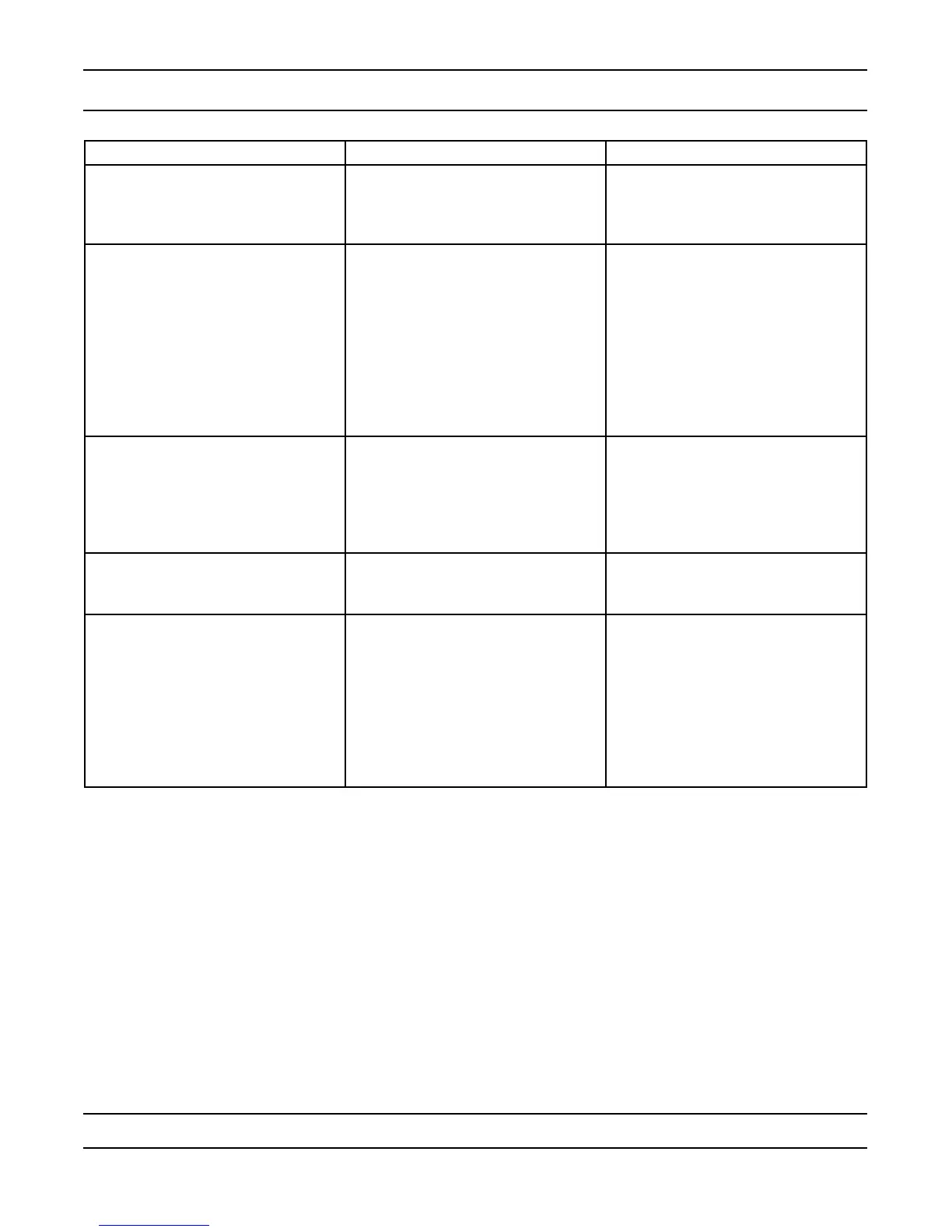

Problem Cause Correction

3. Unit uses too much salt. A. Improper salt setting.

B. Excessive water in brine

tank.

A. Check salt usage and salt

setting.

B. See problem No. 7.

. Loss of water pressure.

A. Iron buildup in line to water

conditioner.

B. Iron buildup in water condi-

tioner.

C. Inlet of control plugged due

to foreign material broken loose

from pipe by recent work done

on plumbing system.

A. Clean line to water condi-

tioner.

B. Clean control and add

mineral cleaner to mineral bed.

Increase frequency of regen-

eration and/or backwash time.

C. Remove pistons and clean

control.

5. Loss of mineral through drain

line.

A. Air in water system.

B. Drain line ow control too

large.

A. Assure that well system has

proper air eliminator control.

Check for dry well condition.

B. Check to ensure drain line

ow control is sized properly for

your mineral tank.

6. Iron in treated water. A. Fouled mineral bed. A. Check backwash, brine draw

and brine tank ll. Increase

frequency of regeneration.

7. Excessive water in brine

tank.

A. Plugged drain line ow

control.

B. Plugged injector system.

C. Timer not cycling.

D. Foreign material in brine

valve.

E. Foreign material in brine line

ow control.

F. Power loss during brine ll.

A. Check ow control.

B. Clean injector and screen.

C. Replace timer.

D. Replace brine valve seat

and clean valve.

E. Clean brine line ow control.

F. Check power source.

Loading...

Loading...