Applicable standards

● If the coupling is intended for use under normal operating conditions, mill the parallel

keyway according to DIN 6885/1 ISO JS9.

● If the coupling is intended for reversing operation, mill the parallel keyway according to

DIN 6885/1 ISO P9.

● If you want to mill a parallel keyway that does not correspond to DIN 6885/1, please consult

Flender.

5.1.3 Machining an axial locking mechanism

The coupling part is secured by a set screw or an end plate to prevent axial movements.

Please consult Flender if you want to use an end plate.

Note the following when using a set screw:

● Diameter and axial position of the tapped hole in the hub

● Position of the tapped hole with respect to the parallel keyway

● Selection of the set screw

Diameter and axial position of the tapped hole in the hub

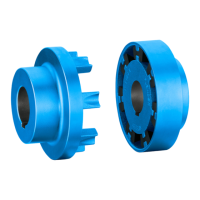

The following diagram shows the axial position of the tapped hole.

① Coupling part 1; axial position of the tapped hole up to size 125 / 135

② Coupling part 1; axial position of the tapped hole as of size 140 / 152

③ Coupling part 2

④ Coupling part 4

Figure 5-2 Diameter and axial position of the tapped hole in the hub

Assembly

5.1 Preparatory work

N-EUPEX / N-EUPEX DS 3100en

26 Operating Instructions 10/2017

Loading...

Loading...