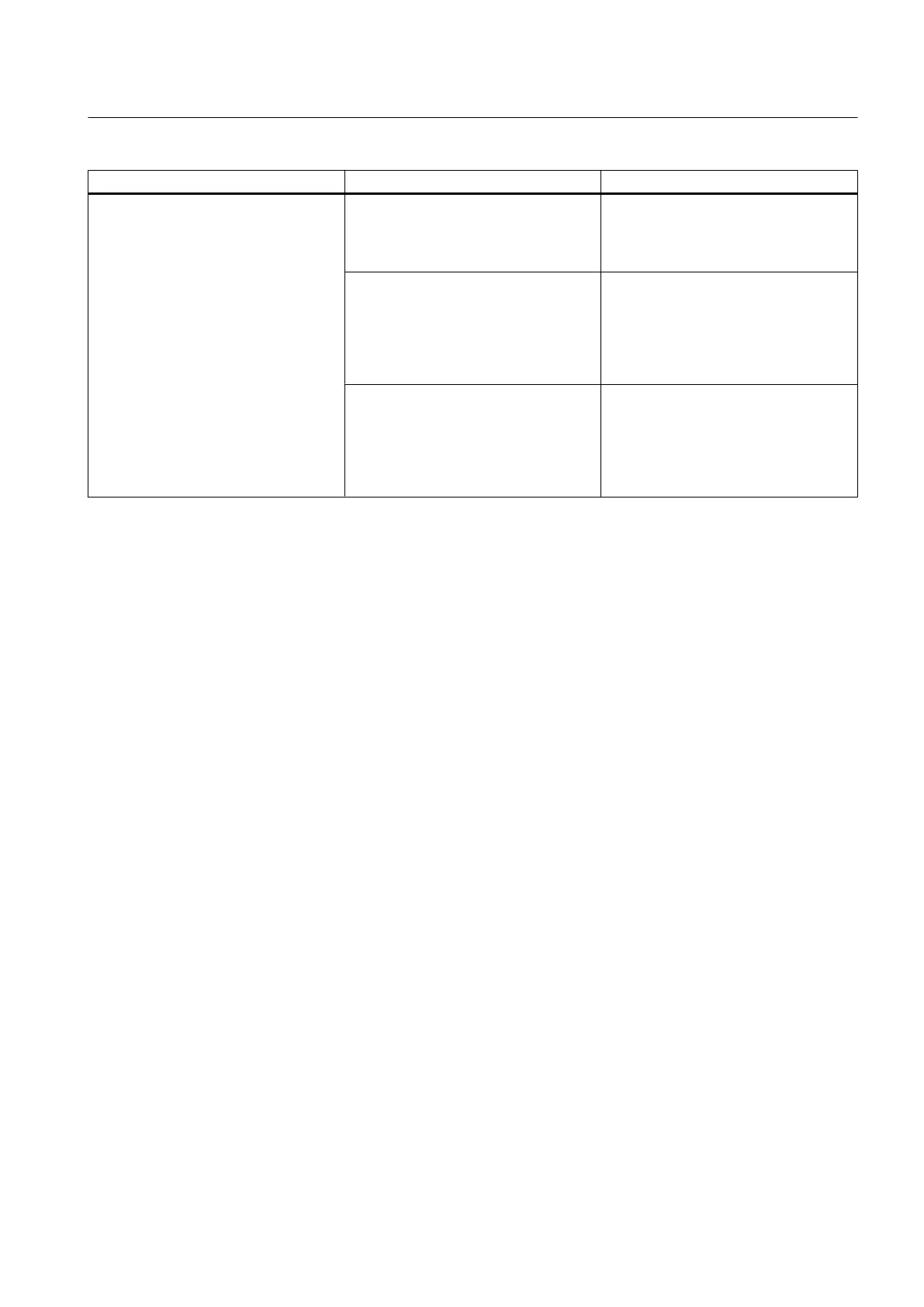

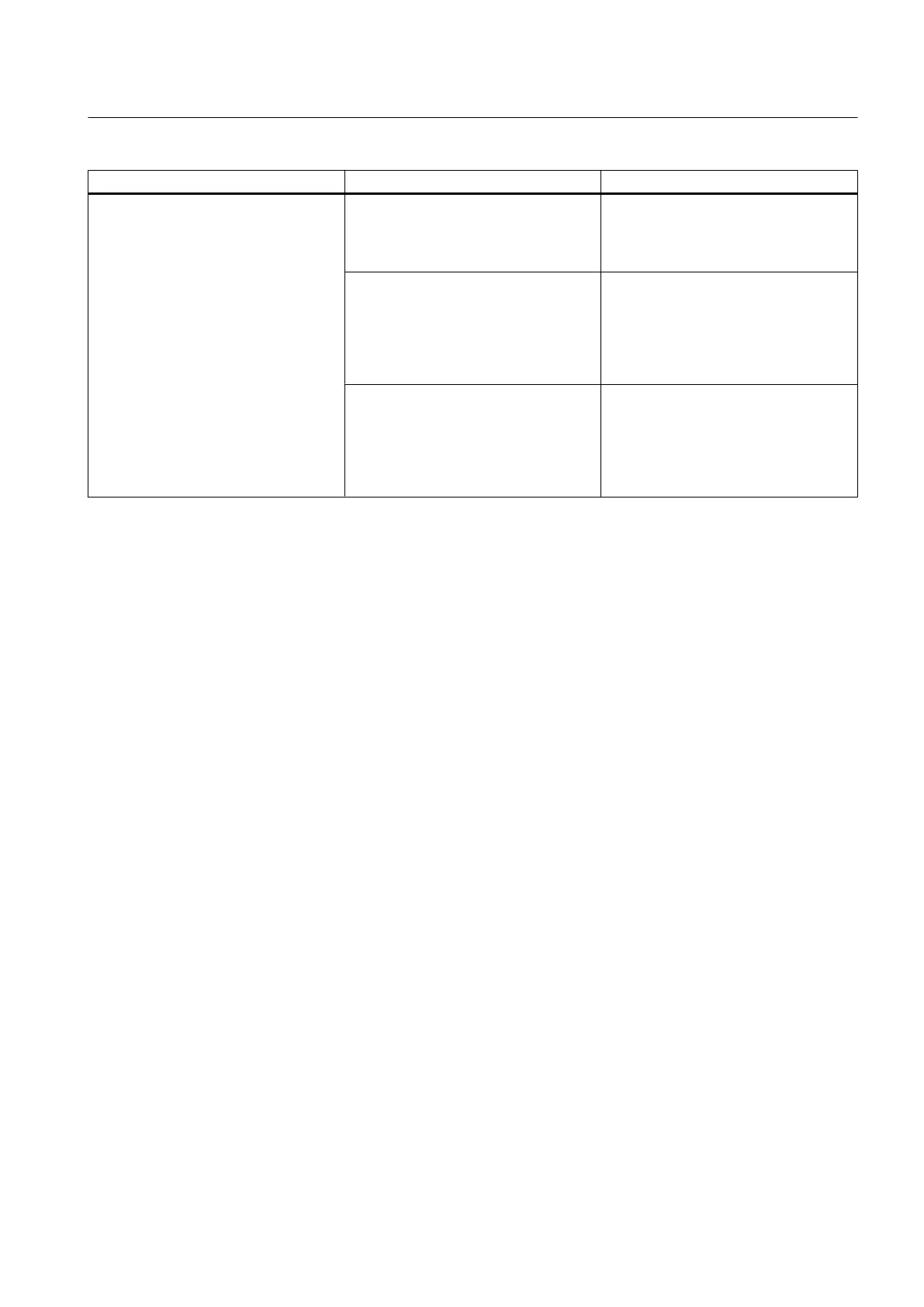

Fault Cause Rectification

Presence of vibration Coupling not suitable for the operating

conditions.

Check the possible causes given in sec‐

tion Unsuitable coupling (Page 39).

Use a coupling that is suitable for the

operating conditions.

Incorrect assembly of the coupling.

Check the possible causes given in sec‐

tions Assembly-related causes

(Page 39) and Specific installation-rela‐

ted and maintenance-related causes

(Page 40).

Reassemble the coupling in accordance

with these instructions.

Please observe all the stipulations and

requirements given in chapter Assem‐

bly (Page 23).

Incorrect maintenance of the coupling.

Check the possible causes given in sec‐

tions Maintenance-related causes

(Page 40) and Specific installation-rela‐

ted and maintenance-related causes

(Page 40).

Please observe all the stipulations and

requirements given in chapter Servic‐

ing (Page 43).

7.2.2.2 Possible causes

Unsuitable coupling

● Important information on the description of the drive unit and the environment were not

available when the coupling was chosen.

● System torque too high and/or torque dynamics not permissible.

● System speed too high.

● Application factor not selected correctly.

● Chemically aggressive environment not taken into consideration.

● Coupling not suitable for the ambient temperature.

● Diameter and/or assigned fit of the finished bore not permissible.

● Width across corners of the parallel keyways greater than the width across corners of the

parallel keyways in accordance with DIN 6885/1 for the maximum permissible bore.

● Shaft-hub connection incorrectly sized.

● Maximum permissible load conditions not taken into consideration.

● Maximum permissible overload conditions not taken into consideration.

● Dynamic load conditions not taken into consideration.

● Coupling and the machine and/or drive train form a critical torsional, axial or bending

vibration system.

Assembly-related causes

● Damaged parts installed.

● Shaft diameter outside the stipulated tolerance range.

Operation

7.2 Faults - causes and rectification

N-EUPEX / N-EUPEX DS 3100en

Operating Instructions 10/2017 39

Loading...

Loading...