© Flow International Corporation M-416 | 35

CHAPTER 3

Maintenance & Troubleshooting

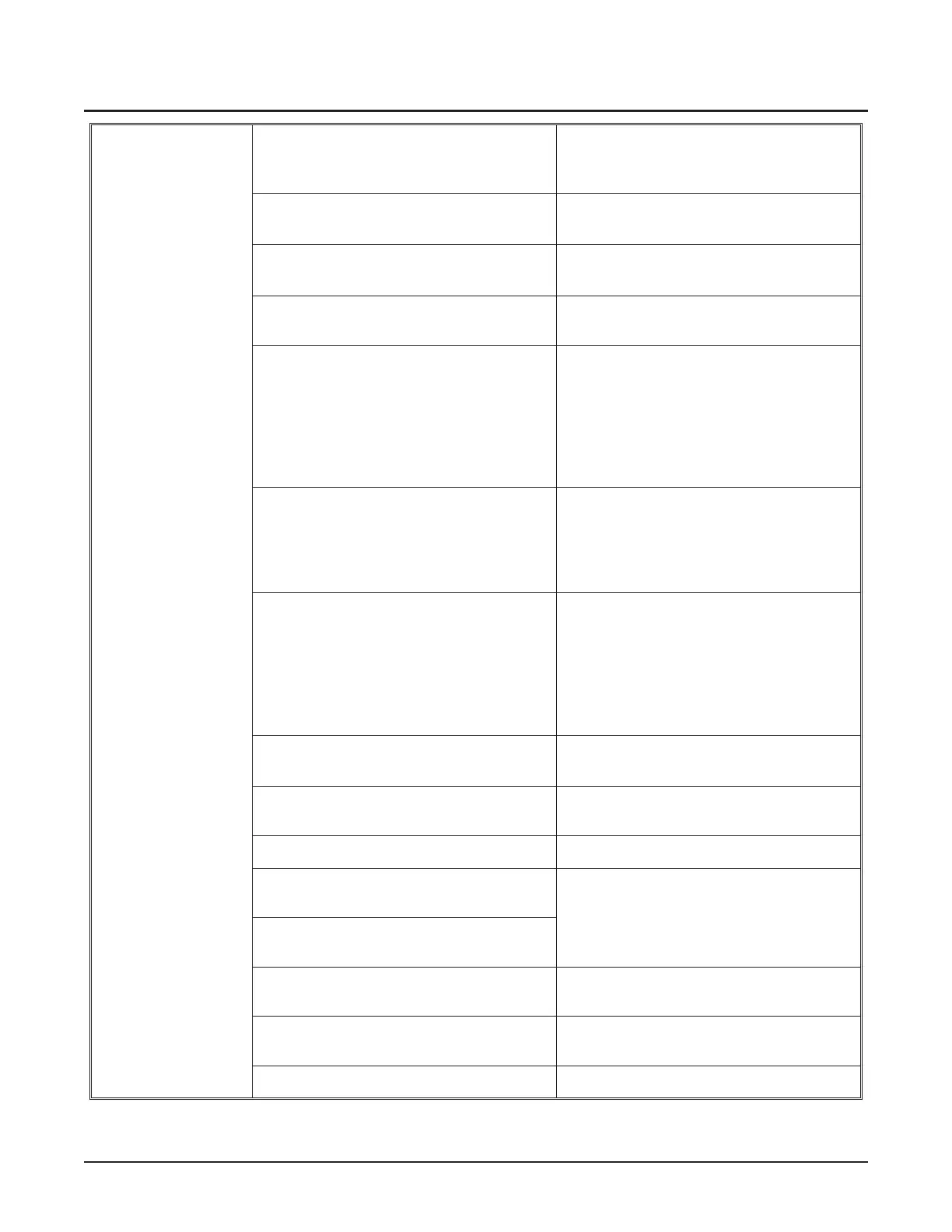

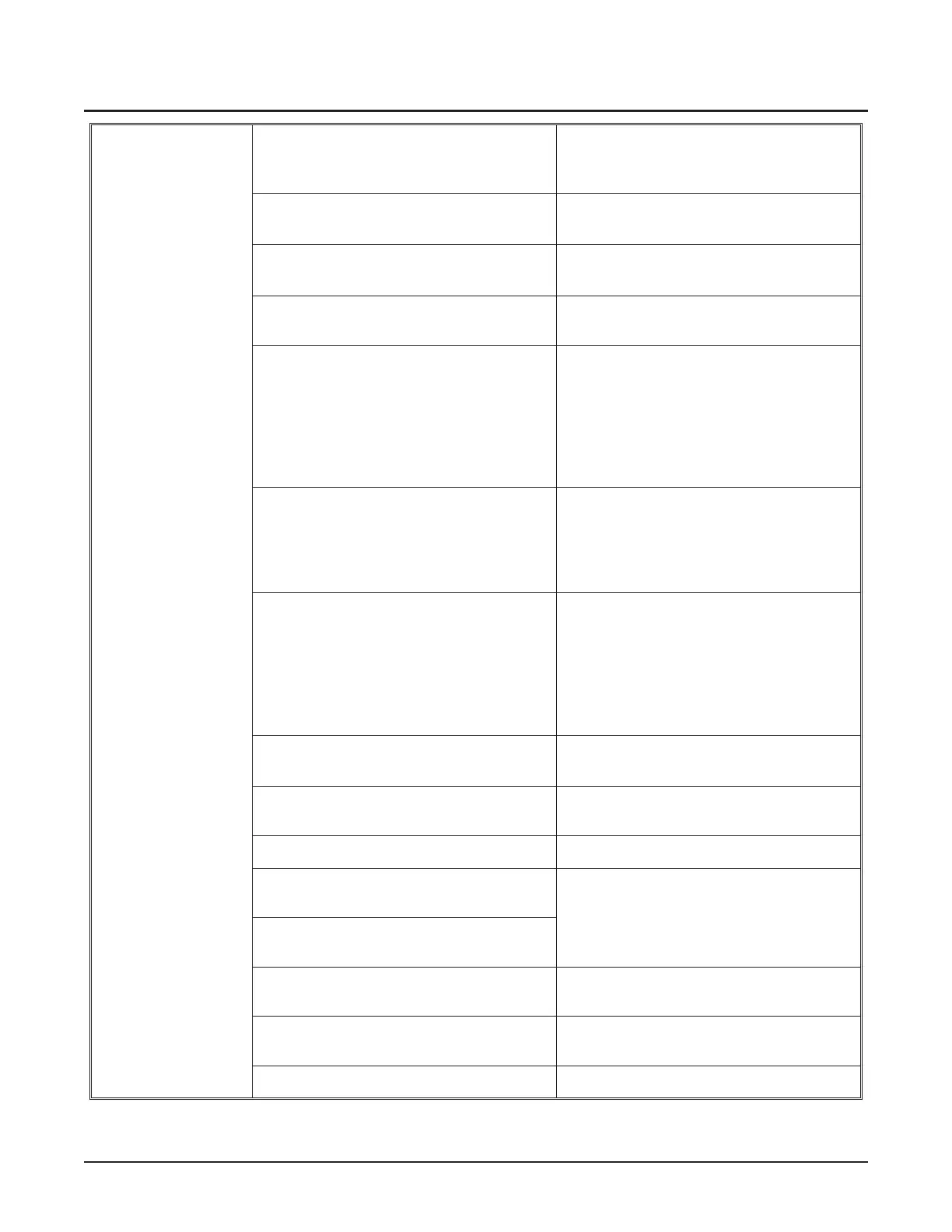

My pump does not

produce the pressure

requested from

FlowMaster

(continued).

Insufficient water pressure or volume from

operator supply.

•

Check water source (flow rate and pres

-

sure; filtration system)

•

Check hoses and fittings for leaks/kinks

Failed inlet check valve (damaged surfaces,

erosion, debris, etc.).

•

Rebuild per service procedure

•

Replace check valve assembly

Failed outlet check valve (damaged surfaces,

erosion, debris, etc.).

•

Rebuild per service procedure

•

Replace check valve assembly

Failed check valve body (damaged seating

surface, cracked indentations from debris).

Replace check valve body.

Failed UHP seal. May be an indication of a failed plunger, im

-

proper tie rod loading, elevated inlet water

temperature, or lack of cooling water (clogged

cooling ports).

•

Inspect seal carrier and plungers (replace as

necessary)

•

Replace dynamic seal and rod seal

Leaking UHP cylinder.

•

Inspect for cracks

•

Inspect seal carrier and check valve body

contact surfaces for spalling, erosion, or

damage. Replace as necessary.

•

Replace the cylinder

Failed UHP tubing and connections.

• Check gland for proper torque

•

Check collar position

•

Check tubing or fitting for cracks. Replace

as necessary.

•

Check for deformed cone on tubing (may

indicate over-torque). Replace tubing as

necessary.

Failed on/off valve.

•

Install on/off valve service kit

•

Replace on/off valve body

Clogged inlet water filters. Replace filters (see section Changing the filter

elements).

Mis-installed subplate adapter rod seal. Re-install rod seal properly.

Loose wiring connection to the air propor

-

tional control valve.

Check and tighten connections.

Failed or loose connection on the UHP trans

-

mitter.

Failed or improperly calibrated UHP pressure

gauge.

Replace gauge or transmitter (the gauge trans

-

mitter cannot be re-calibrated).

Excessive length of tubing between pump and

pressure gauge.

Call Flow Technical Service.

Failed air proportional control valve. Replace air proportional control valve.

Loading...

Loading...