36 | M-416 ©FlowInternationalCorporation

HYPLEX PRIME PUMP

Maintenance & Service Manual

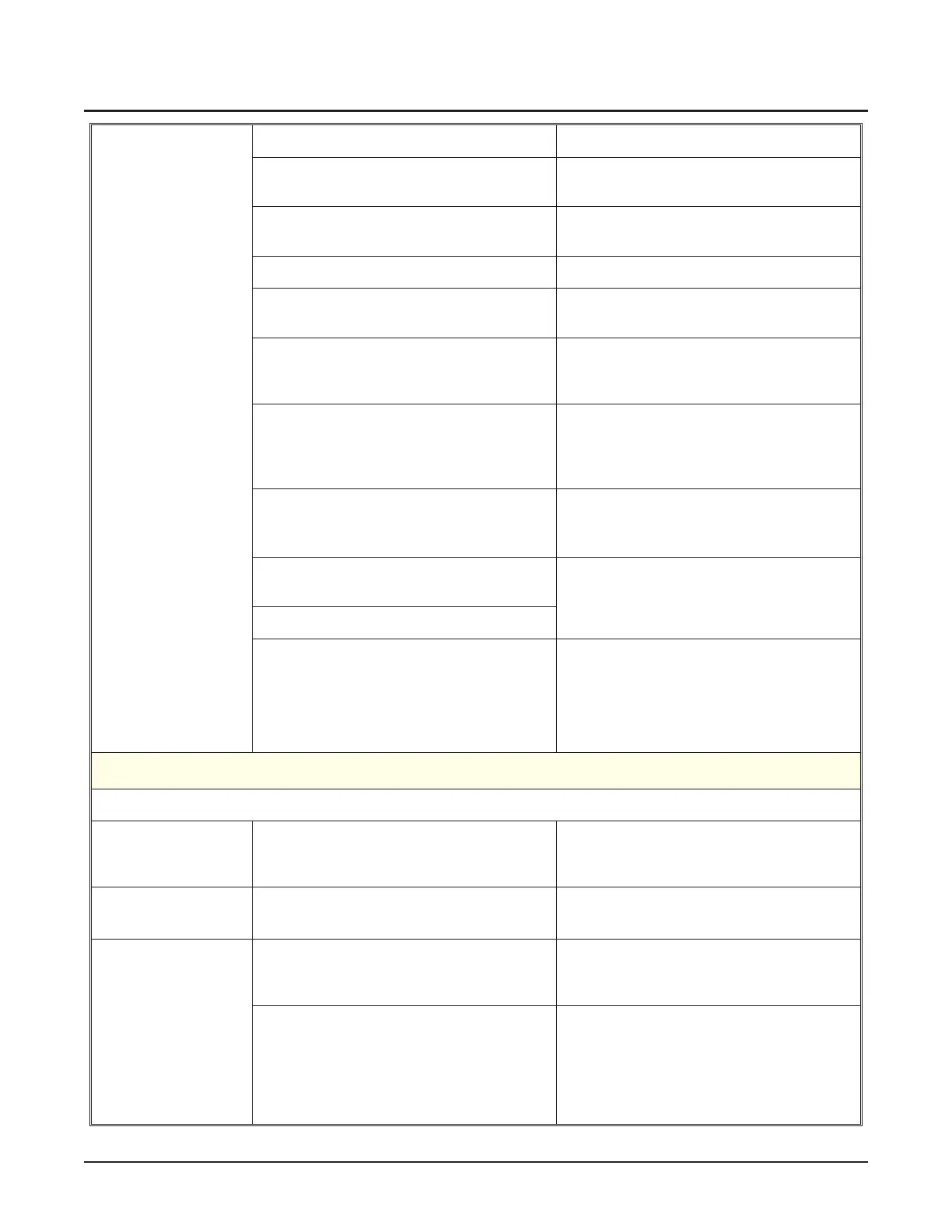

My pump does not

produce the pressure

requested from

FlowMaster

(continued).

Failed or improperly set air relief valve. Replace air relief valve.

Loose fittings or failed hose for low-pressure

water.

Tighten fittings or replace hose.

Improper pulley ratio for power frequency. Verify required pulley sizes for input power

(see Interface illustrations for part numbers).

Missing 3-phase power leg. Call a certified electrician.

Incorrect version of computer code (specifi

-

cally FlowMaster).

Call Flow Technical Service for correct revision

number and install correct version.

Worn PCV poppet and seat. Install PCV maintenance kit (see section In

-

stalling the pressure control valve maintenance

kit).

Debris in PCV poppet and seat.

•

Clean or remove debris, check for damage

of poppet and seat

•

Ensure proper plumbing of the PCV drain

line

Incorrect motor rotation.

•

Verify and ensure proper rotation

•

Call a certified electrician to swap polarity

on motor

Inlet water supply valve or solenoid failure (or

loose wires).

•

Replace valve

•

Tighten wire fittings

•

Check breaker inside electrical control box

2-way air valve failure or loose wiring.

2-way air valve override switch is improperly

positioned.

Position the override switch to "automatic"

mode.

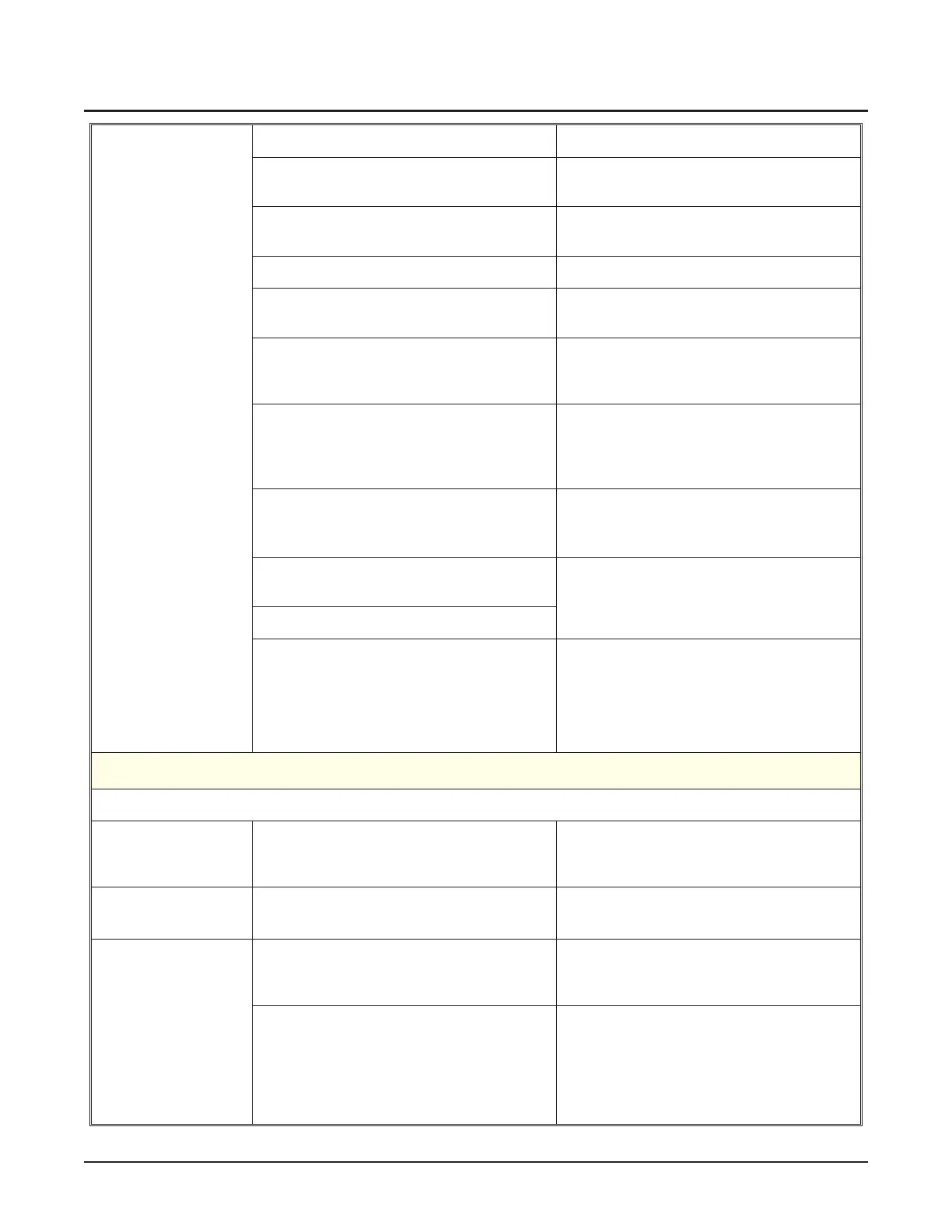

My UHP pressure display is not stable.

A signal fluctuation greater than 5000 psi indicates:

Slow movement

PCV poppet/seat damaged.

Install PCV maintenance kit (see section In

-

stalling the pressure control valve maintenance

kit).

Rapid movement

Check valve is damaged or debris is present.

•

Rebuild per service procedure

•

Replace check valve assembly

Cutting orifice is too large or damaged. Replace with correctly-sized orifice (see sec

-

tion Changing the orifice in your cutting head

manual).

UHP check valve components are damaged

or require maintenance.

Install a Minor or Major Maintenance Kit.

Loading...

Loading...