© Flow International Corporation M-416 | 37

CHAPTER 3

Maintenance & Troubleshooting

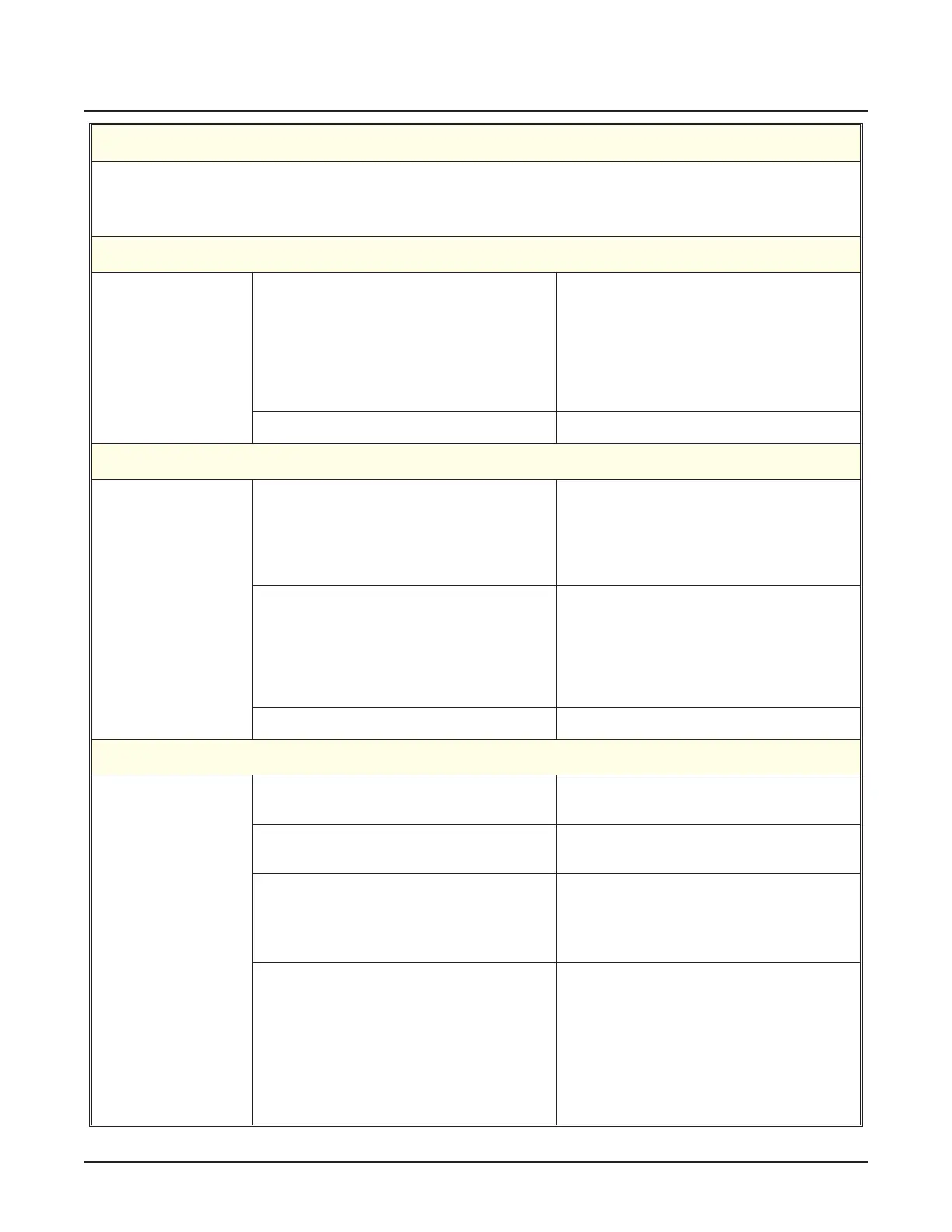

My UHP pressure seems to change depending on the state of the on/off valve (whether it's on or off).

Some degree of pressure change (2000-3000 psi [138-207 bar]) with the switching of the on/off valve is normal.

My pump does not start.

Pump not wired.

•

Check that operator-supplied service dis

-

connect is on and all fuses are properly

sized and functional

•

Check that the motor starter disconnect is

turned on

•

Check for loose wiring. Call a certified

electrician.

Tripped circuit breaker in control box. Call Flow Technical Service.

My pump starts but immediately shuts down.

Crankcase oil temperature too high (can be

validated through FlowMaster Advanced

Diagnostics).

•

Ensure proper oil level

•

Verify electrical sensor is functioning prop-

erly and replace if necessary

•

Replace crankcase if all other options have

been exhausted

Low inlet water pressure.

•

Validate proper operation of inlet solenoid,

pressure gauges and switches; replace if

necessary

•

Verify adequate operator-supplied water

source

•

Check fuses

Motor overload shutdown has been tripped. Check with a certified electrician.

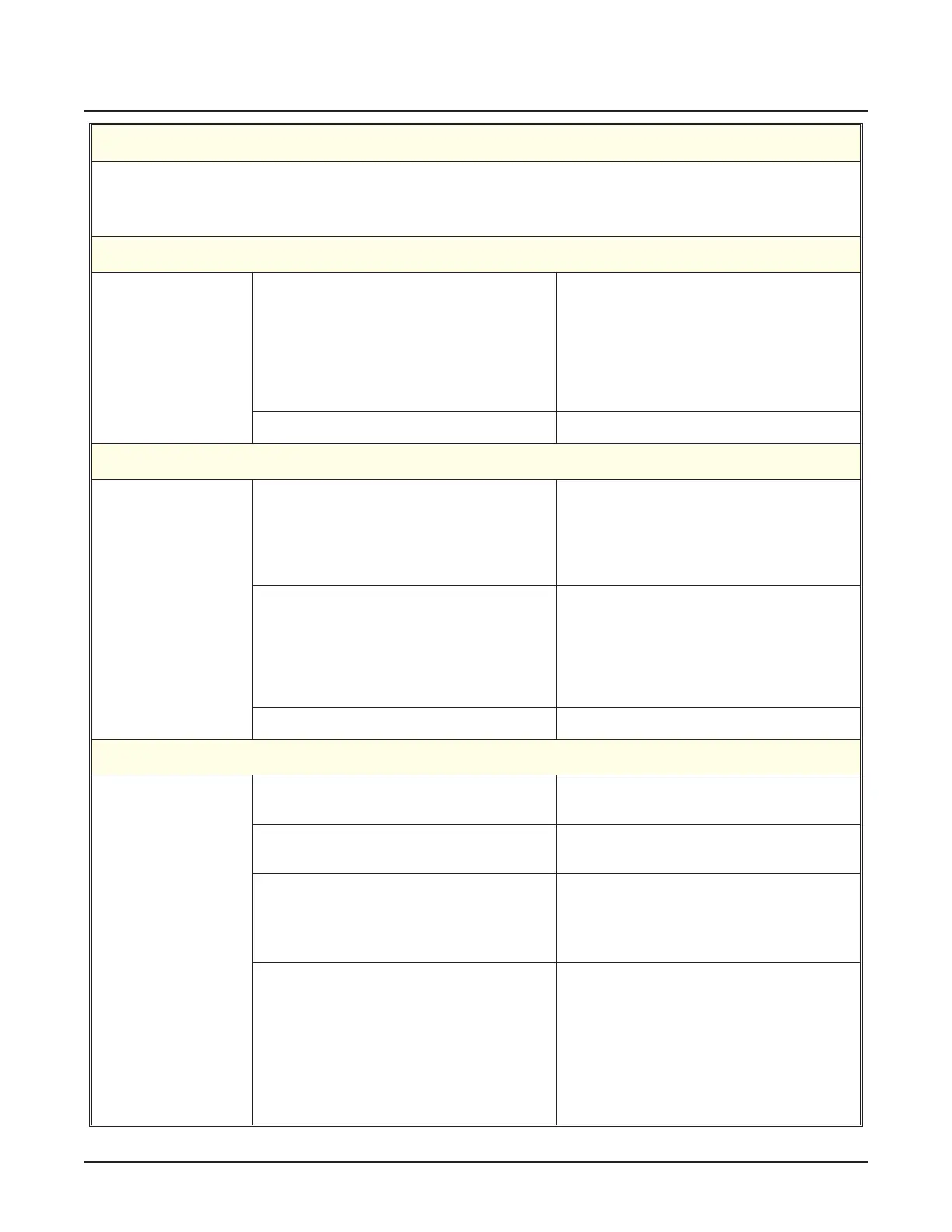

My inlet water gauges are not reading pressure.

Operator-supplied water not on, or supply

pressure is insufficient.

Turn water on, inspect water supply pressure.

Failed inlet pressure gauges or gauge snubbing

orifices are clogged.

Replace gauges or clean snubbing orifices.

Inlet solenoid valve not opening.

•

Verify that an open signal is sent to the

valve

•

Check wiring and tighten or replace

•

Check fuses

Kinked or obstructed gauge line. Re-position the line or replace if damaged.

Loading...

Loading...