38 | M-416 ©FlowInternationalCorporation

HYPLEX PRIME PUMP

Maintenance & Service Manual

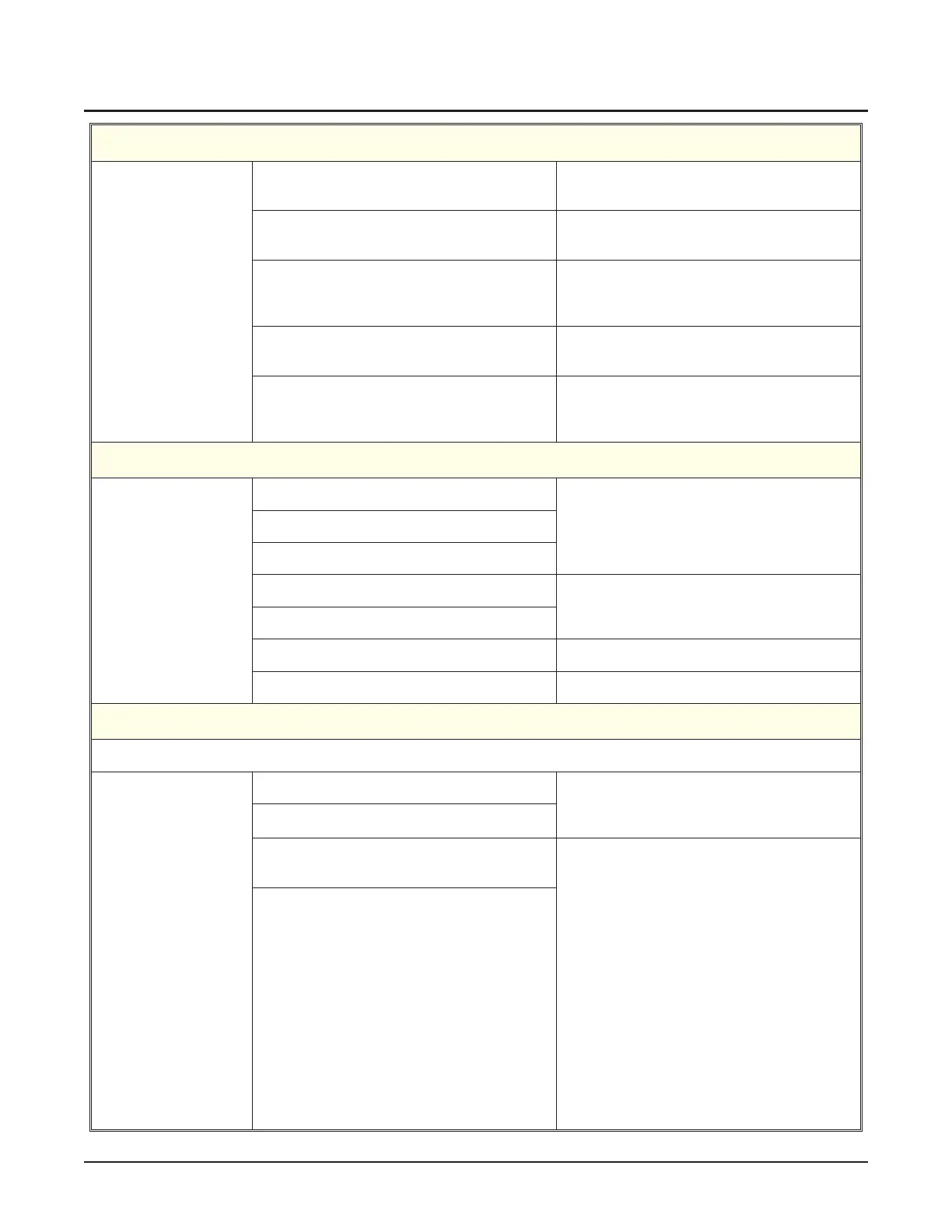

My pump's inlet water filters are clogging too quickly.

Missing (or clogged) operator-supplied

5 micron inlet water pre-filter.

Install or replace the pre-filter.

Improper inlet water plumbing material (use

of iron or galvanized steel).

Call Flow Technical Service.

Use of alternate filter vendor (non-Flow). Flow recommends purchasing components

from Flow International Corporation to ensure

part quality and safety.

Recent upstream water supply maintenance

or change of municipal supply.

Call Flow Technical Service.

Filter element order is reversed. Correct the order of the filters. The correct fil

-

ter element order is indicated by labels on the

pump frame.

My pump seems to be running hotter than previously

Failed inlet check valve. Install a Minor or Major Maintenance Kit.

Failed outlet check valve.

Failed UHP seal.

Low oil level in crankcase. Add or replace oil with correct oil

(see Specifications section).

Bad or old oil in crankcase.

Blocked or kinked cooling water hose. Re-position hose or replace if damaged.

Air temperature is above specified limit. Call Flow Technical Service.

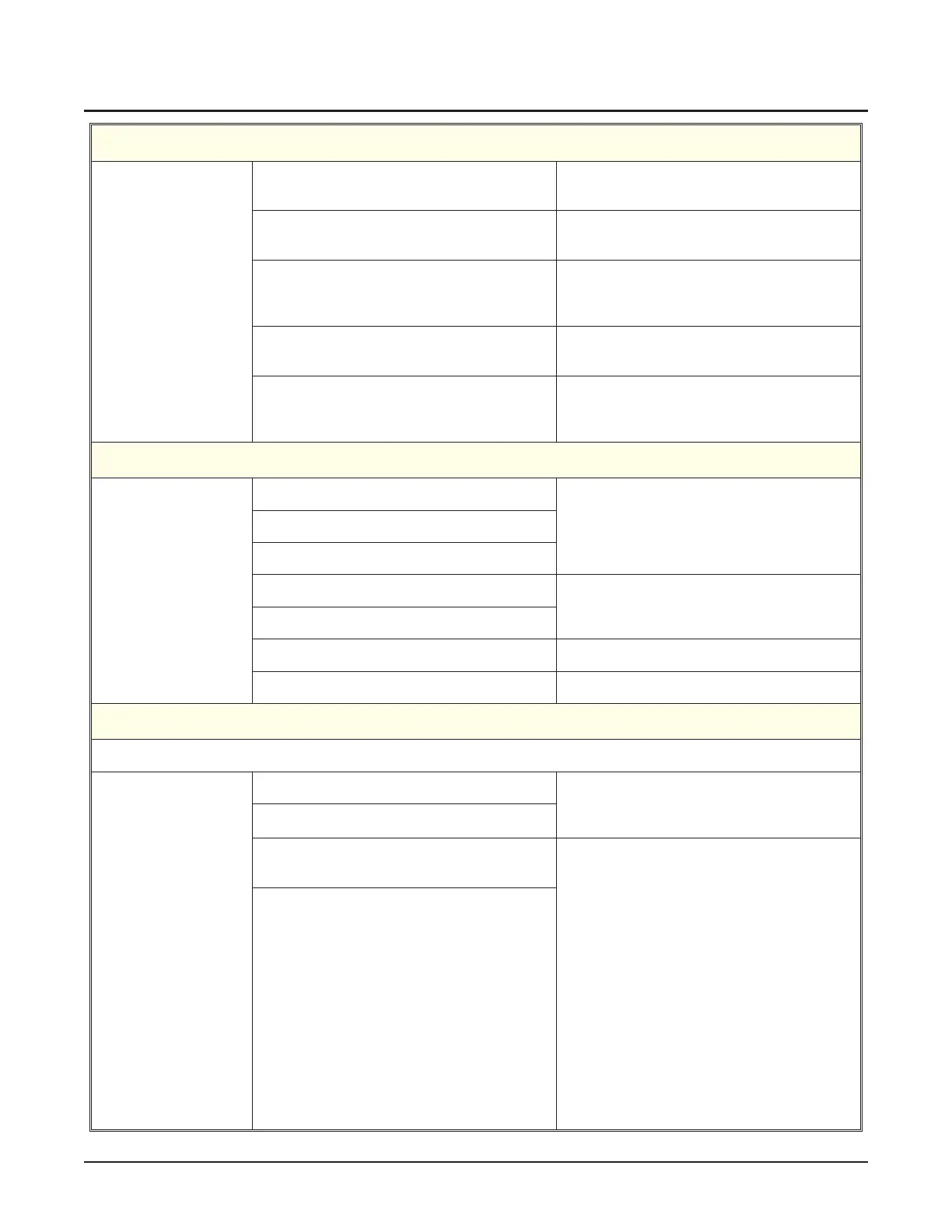

My pump's UHP tubing is failing quickly

Note: Tubing failures occur more frequently with age.

Use of alternate tubing vendor (non-Flow). Flow recommends purchasing components

from Flow International Corporation to ensure

part quality and safety.

Use of incorrect pressure-rated tubing.

Frequency of low-pressure pierces will shorten

tubing life.

Call Flow Technical Service.

UHP tubing length is causing "standing pres

-

sure spikes."

Loading...

Loading...