Disassembly

1. Push in the E-stop.

WARNING

Place the main electrical disconnect OFF and bleed down

all high-pressure lines. Place an “Out of Service” tag on the

main electrical disconnect and lock it out. Failure to do so

may result in equipment damage or injury to personnel.

2. Disconnect all high-pressure and low-pressure inter

-

face connections to access the tie rods. Place the

manifold and PCV assembly combination aside.

3. Use the pressure loading tool to unload the tie rods

(see Unloading the tie rods on Page 43).

For each of the three high-pressure cylinders

4. Remove the end cap, high-pressure cylinder, inlet

poppet, springs, filler tube, and sleeve. Discard the

inlet poppet and spring.

5. Remove and discard the o-ring from the ID of the

high-pressure cylinder.

6. Slide the dynamic seal carrier off the plunger if it did

not come out with the cylinder. Remove and discard

dynamic seal and rod seal.

CAUTION

Use care when removing dynamic seal and rod

seal. Do not scratch or nick seal carrier bores.

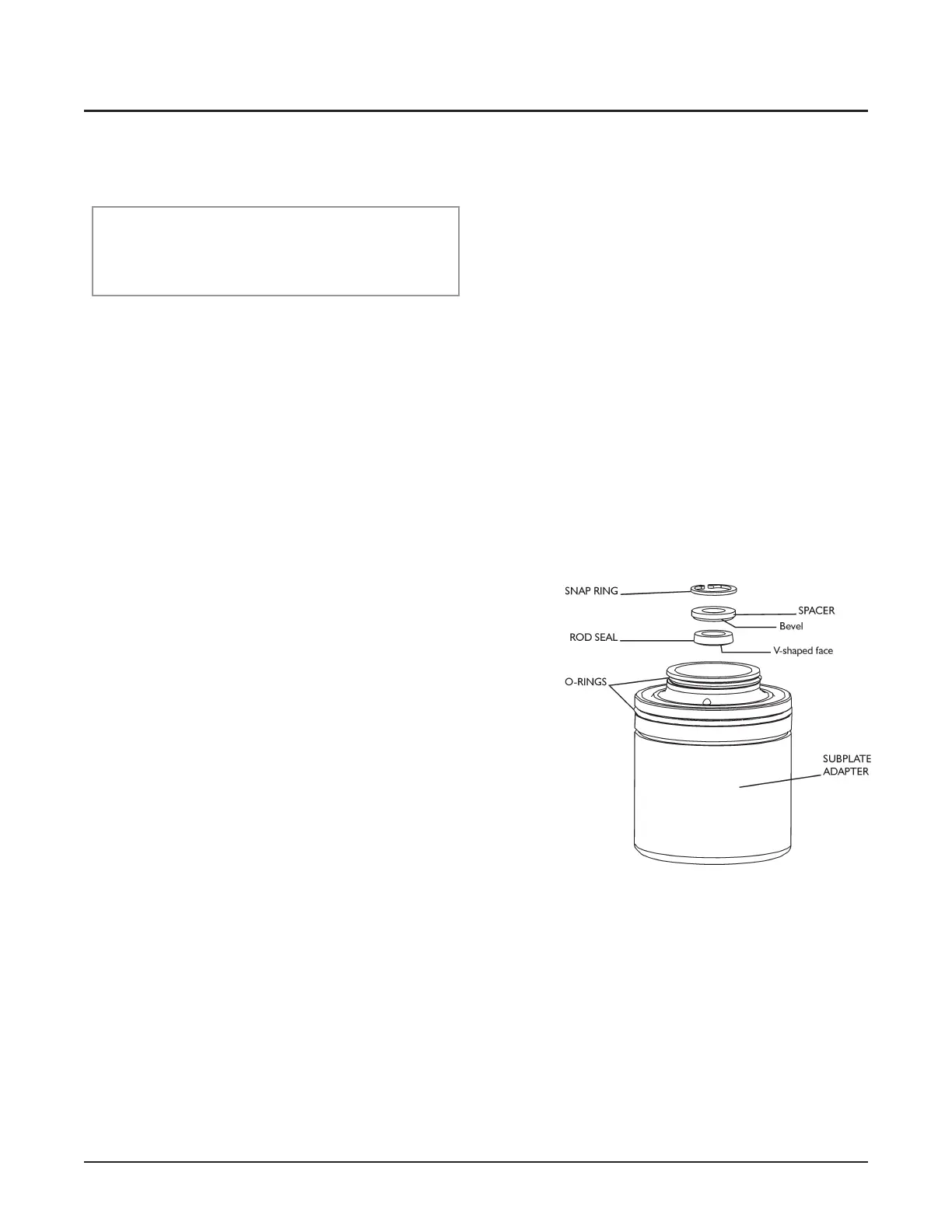

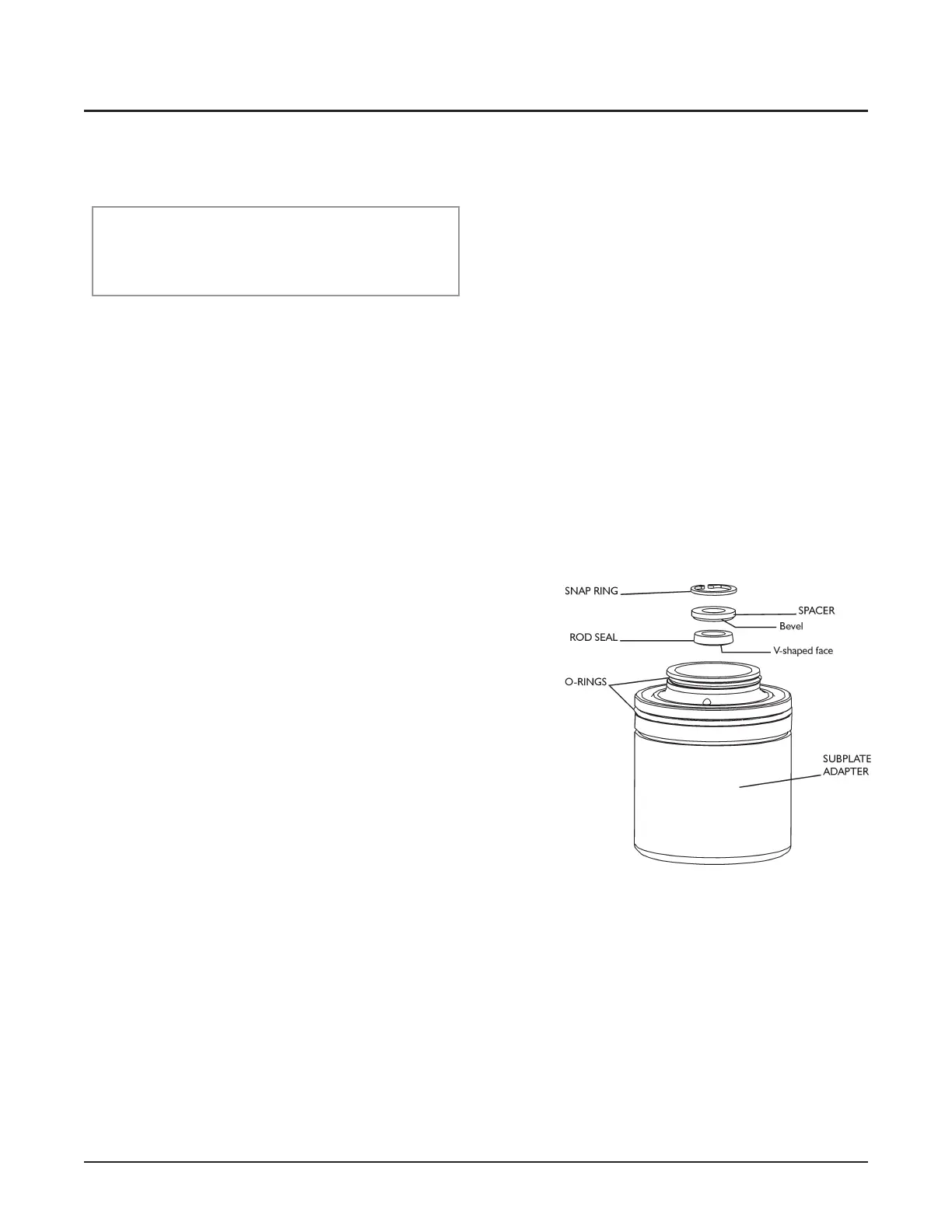

7. Remove the subplate adapter. If necessary, use pry

bars or screwdrivers to remove the adapter. Remove

the snap ring from the subplate adapter using snap

ring pliers. Remove the spacer and seal. Remove the

two o-rings from the outer diameter of the adapter.

Discard the seal, o-rings, and snap ring. Keep the

spacer for reuse.

56 | M-416 ©FlowInternationalCorporation

HYPLEX PRIME PUMP

Maintenance & Service Manual

Loading...

Loading...