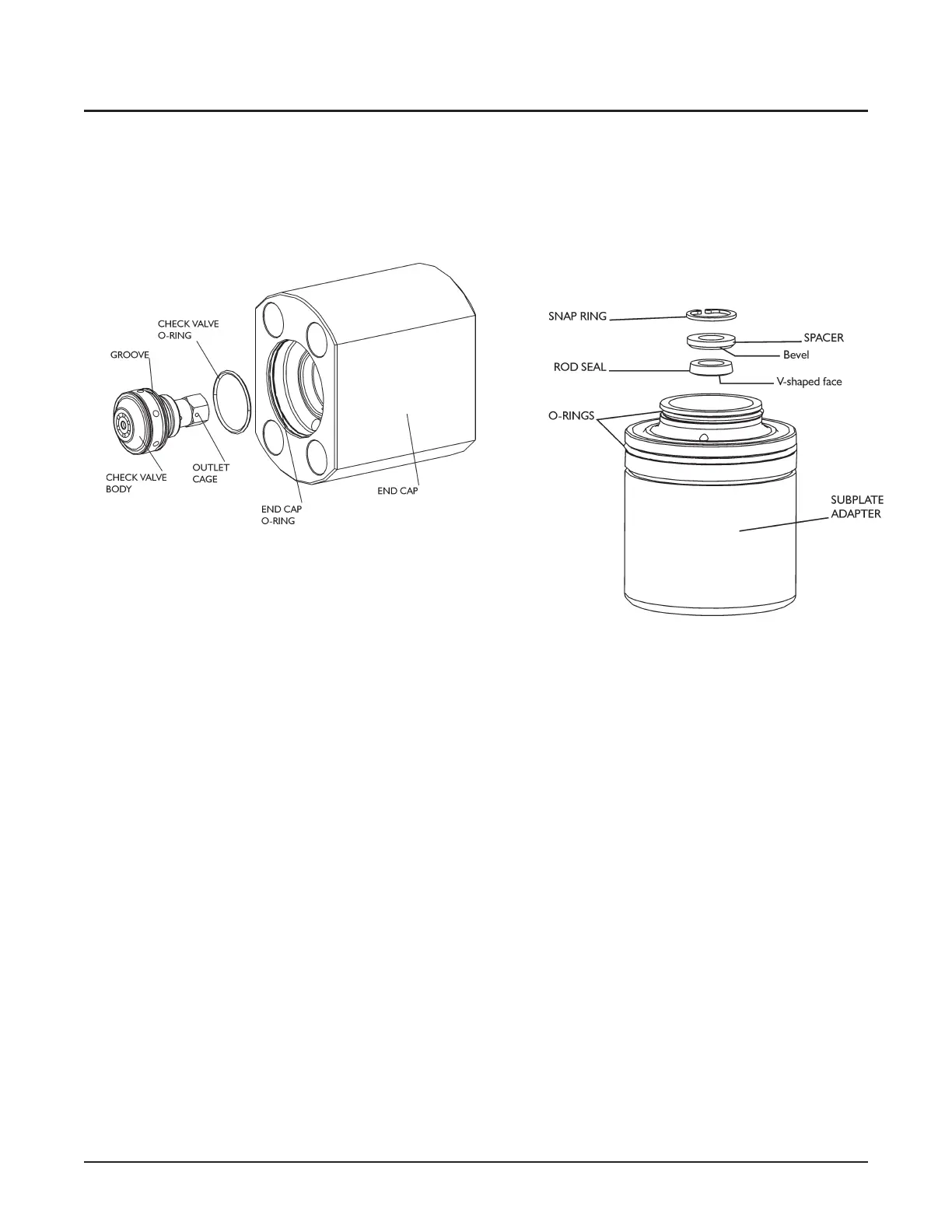

Assemble the end cap

1. Lightly lubricate the new check valve o-ring with

o-ring lube and install it into the grooves on the

check valve body.

2. Lightly lubricate the end cap o-ring with o-ring lube

and install it in the groove in the inner diameter of

the end cap.

3. With the outlet cage facing the end cap, insert the

check valve body into the end cap.

Repeat for the remaining end caps.

Check plunger torque

1. Install the plunger nut tool over the plunger and

plunger nut. Use a torque wrench to torque the

plunger nut to 20 ft-lb (27 N-m).

2. Rotate the pulley to fully extend the next plunger to

be checked.

Repeat steps for the remaining plungers. When finished,

wipe off dirt and grease from all three plungers.

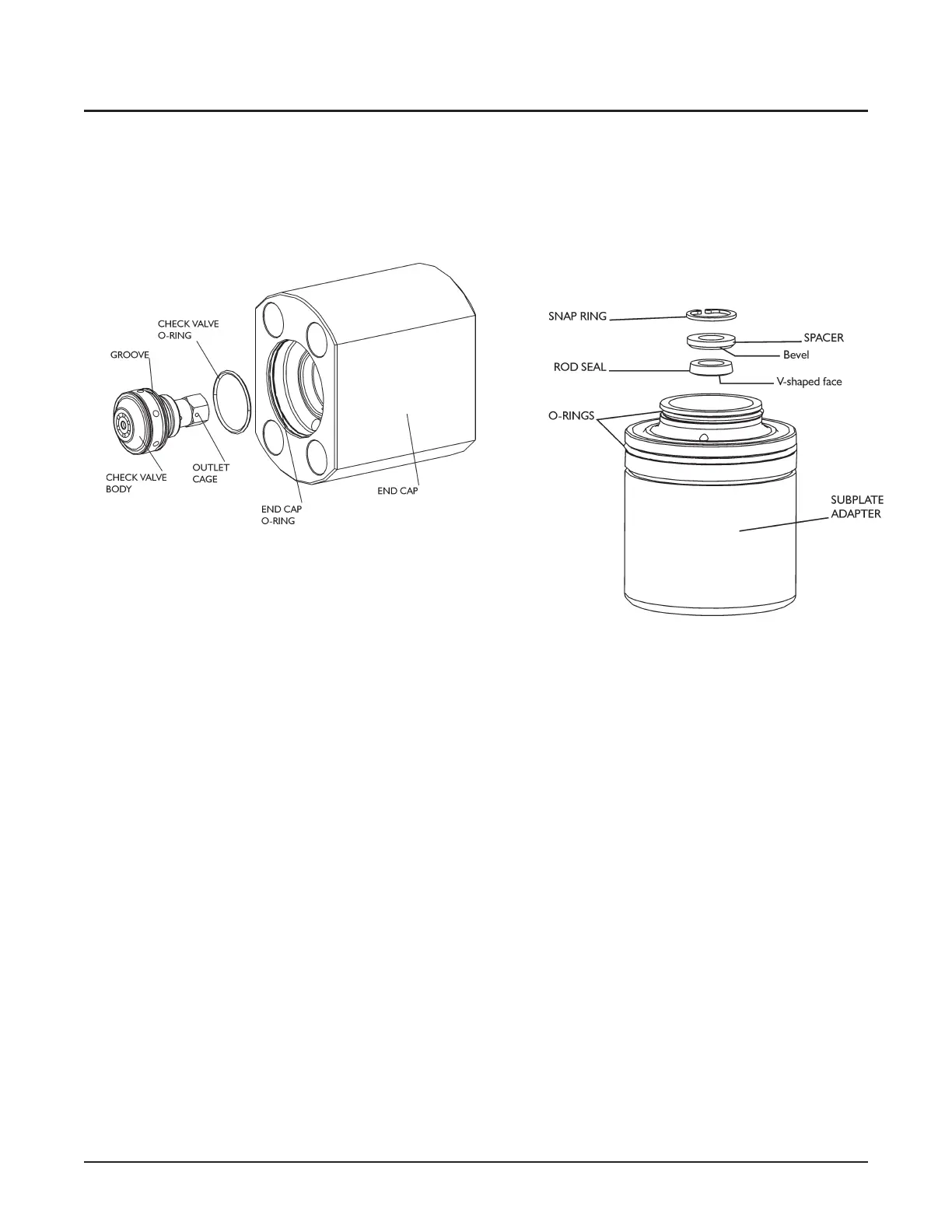

Rebuild the subplate adapter

1. Make sure the tie rods are firmly seated in the

subplate.

Note: Hand tight is sufficient.

2. With the v-shaped face toward the subplate adapter,

install the new rod seal in the counterbore of the

subplate adapter.

3. Place the new spacer in the counterbore with the

chamfered side down (toward the newly-installed

seal).

4. Secure the rod seal and spacer with the new

snap ring.

5. Lubricate and install the two new o-rings onto the

adapter, and slide the adapter over the plunger until

it engages the counterbore of the subplate.

Repeat Steps 1-5 for the remaining subplate adapters

© Flow International Corporation M-416 | 59

CHAPTER 4

Service

Loading...

Loading...