Lap inlet face of check valve body

13. Use the glass lapping plate from the tool kit and

320 grit lapping paper from the repair kit. Lightly

wet the paper with water.

14. Place the check valve body with the inlet face

against the lapping paper. With a light downward

pressure, lap the body in a figure-8 pattern.

CAUTION

Be very careful not to rock the check valve body

while lapping the surface—flatness is very critical.

After 10-12 laps, rotate the check valve body 45°

and continue lapping until the surface has a smooth

matte finish free of any deep scratches or signs of

deformation from the inlet poppet. Re-wet the pa

-

per as needed.

15. Thoroughly clean the check valve body openings to

remove particles from the lapping process.

Installation and reassembly

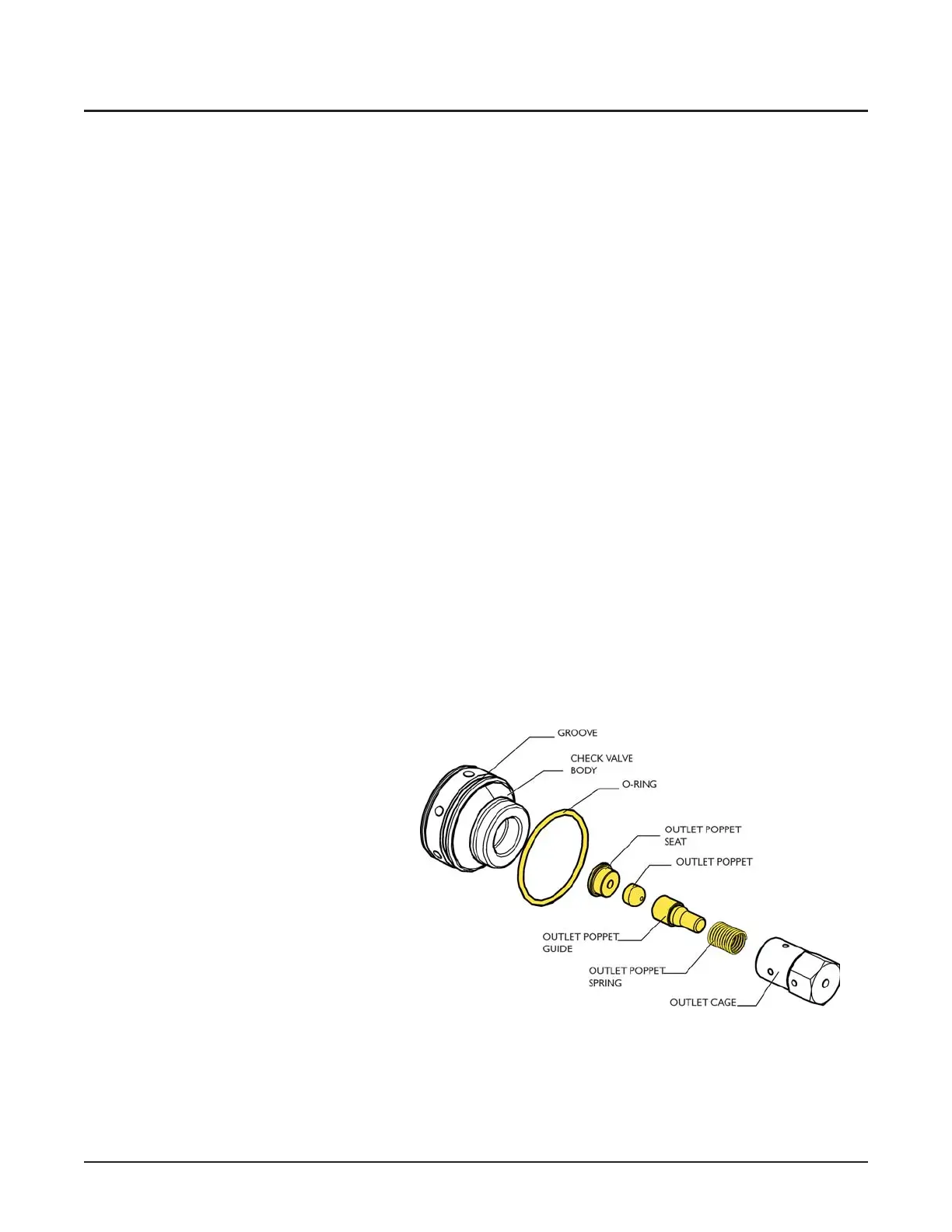

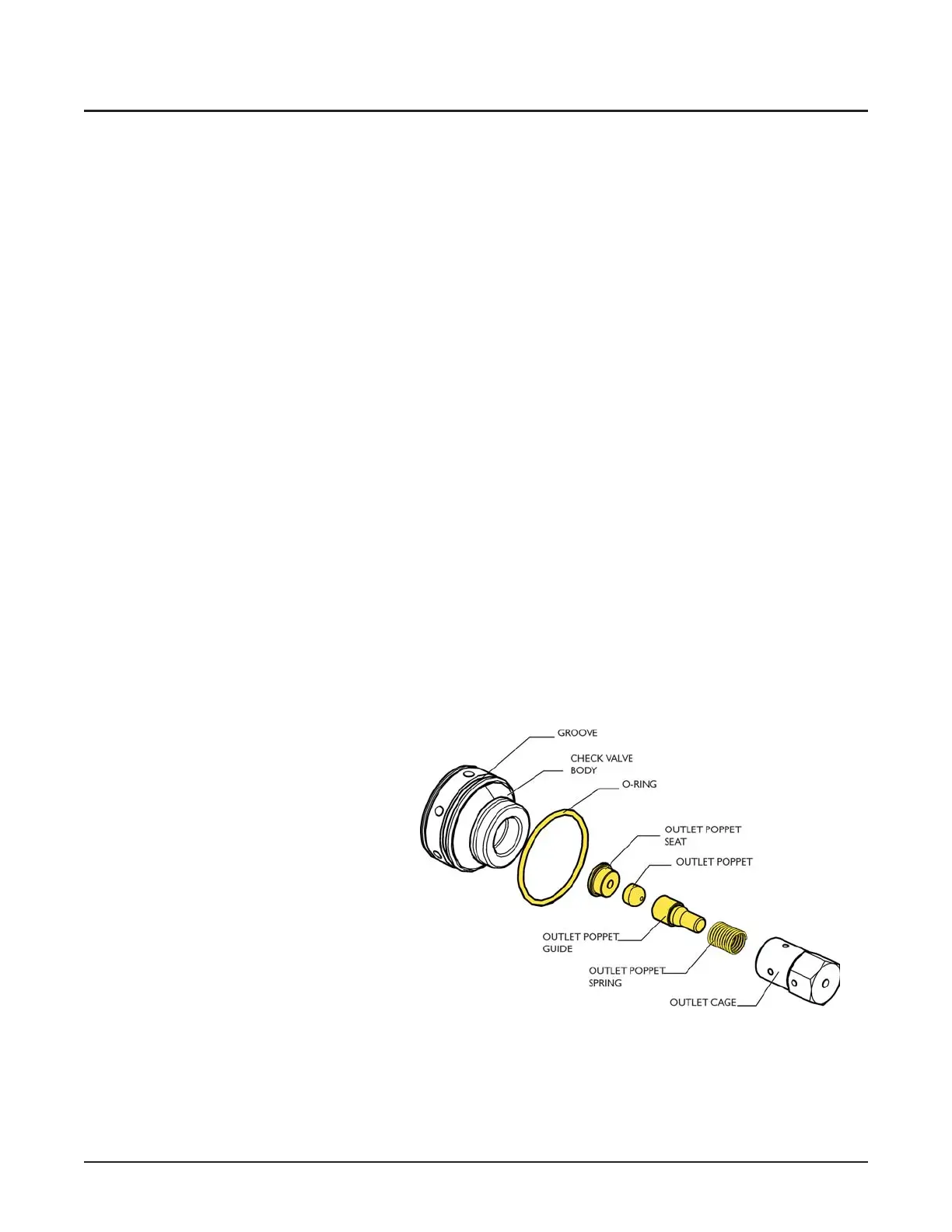

Assemble the check valve

1. Insert the new outlet poppet into the new outlet

poppet guide.

Note: Install poppet into the outlet poppet guide as

shown, with the radiused back of the outlet poppet

going in first. The counterbore in the outlet poppet

is visible after installation

2. Place the new outlet poppet spring around the

guide. The spring should be loose on the guide.

3. Place the assembly into the outlet cage along with

the outlet poppet seat.

4. Hold the outlet cage assembly (threaded end of the

outlet cage facing up), so that the installed compo

-

nents will not fall out. Apply a thin film of Blue Lu

-

bricant to the threads of the outlet cage.

5. Carefully thread the check valve body onto the

outlet cage assembly.

6. Secure the check valve body in the rebuild clamp

with the inlet face downward.

7. Secure the rebuild clamp in a vise. Torque the outlet

cage to 30 ft-lb (41 N-m).

Repeat Steps 1–7 for the remaining check valves.

58 | M-416 ©FlowInternationalCorporation

HYPLEX PRIME PUMP

Maintenance & Service Manual

Loading...

Loading...