MAINTENANCE

GENERAL

INFORMATION

4-17.

DISPLAY

REMOVAL

4-18.

Use the following procedure to remove

the

LCD:

1. Preform the Main

PCB

Access

procedure.

2. Turn the instrument right side up.

3. Remove

the two screws that connect

the Main

PCB

Assembly and the Front Panel

Assembly.

The screws are

located at the

right front

of the

instrument.

4.

Carefully

slide the front panel

forward

until it

is

clear of the switches and

the

LCD.

Let

the

Front Panel

Assembly

drop

clear of the

LCD.

5. Remove the two screws connecting

the

LCD to

the Main PCB Assembly.

6. Place your fingernail under the grey

tabs on

the

display frame and lift

them

free

of the

screwposts

on

the

display mounting

bracket.

7. Rotate the display frame

forward

and

down

until

the

two

hooks on the bottom

of the

display

frame

release the display

mounting

bracket.

8.

The

LCD may now

be

lifted

free

from

the

display mounting bracket.

9 . A small

length

of flat, flexible

material

may

fall

out. This is the “zebra strip”

an elastomeric

strip

of

alternate

areas of conductive

and

non-

conductive

material. When the

screws

are

tightened to hold down the

display

assembly,

the

zebra strip provides electrical

contact

between the

pins

on the LCD and

the land

pattern on the Main PCB.

The zebra

strip

is

located in a channel on the

display

mounting

bracket.

10. To reassemble, reverse

the

previous

procedures

in

a

logical order.

4-19.

Cleaning

CAUTION

Do not use

aromatic

hydrocarbons

or

chlorinated solvents

for

cleaning.

These

solutions will react

with

the

plastic

materials

used in the instrument.

CAUTION

Do

not get the liquid

crystal

display wet.

Remove

the

display assembly before washing

the

pcb

and do not

install

it

until

the pcb has

completely

dried.

4-20.

Clean

the front panel and case

with

a

mild

solution

of

detergent and water. Clean

dust

from

the circuit

board

with

clean,

dry,

low

pressure air

(<20

psi).

Contaminates

can be

removed

from the pcb

with

demineralized

water

and a soft brush (remove the

LCD

before

washing

the

Main PCB Assembly and

avoid

getting

excessive

amounts of

water

on

the

switches).

Dry

with clean,

dry,

low pressure air,

and

then

bake at

50°

C to

60°

C (124°

F to

140°F) for 24

hours.

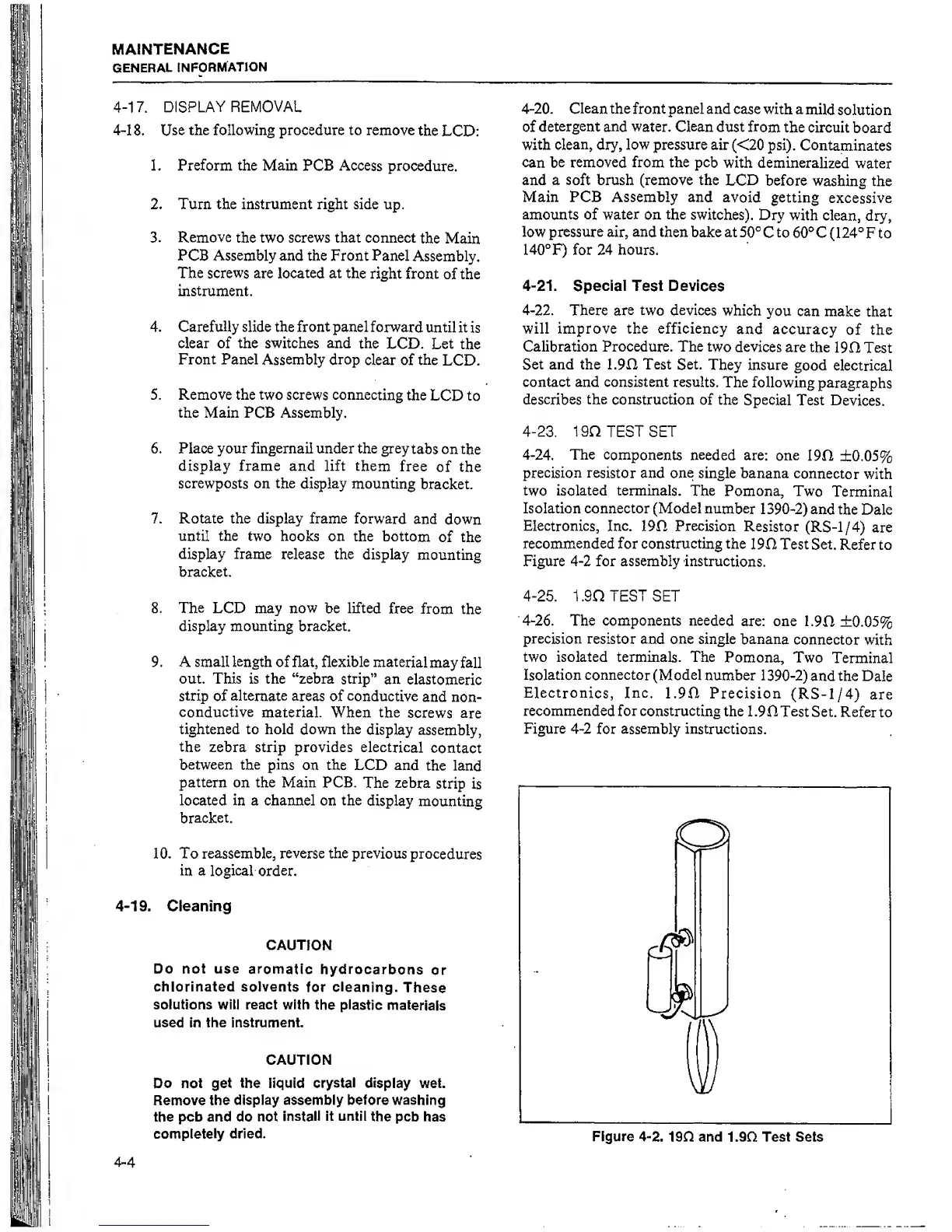

4-21.

Special Test Devices

4-22.

There are two devices

which

you can

make

that

will improve the efficiency

and accuracy

of the

Calibration Procedure. The

two

devices are

the

190 Test

Set and the 1.90 Test Set.

They insure

good electrical

contact and consistent

results.

The following

paragraphs

describes

the

construction

of the

Special

Test

Devices.

4-23.

1

90 TEST SET

4-24.

The

components needed

are:

one

190

±0.05%

precision resistor

and

one

single banana

connector

with

two

isolated terminals.

The Pomona,

Two

Terminal

Isolation connector (Model

number

1390-2)

and

the Dale

Electronics, Inc.

190

Precision

Resistor

(RS-1/4)

are

recommended for constructing the

190 Test Set.

Refer to

Figure

4-2

for assembly instructions.

4-25.

1 .90 TEST SET

4-26.

The components needed

are: one

1.90

±0.05%

precision resistor

and one single

banana

connector

with

two isolated terminals. The

Pomona, Two

Terminal

Isolation connector

(Model

number

1390-2) and the

Dale

Electronics, Inc.

1.90 Precision

(RS-1/4)

are

recommended for

constructing

the

1.90 Test

Set. Refer

to

Figure

4-2

for

assembly instructions.

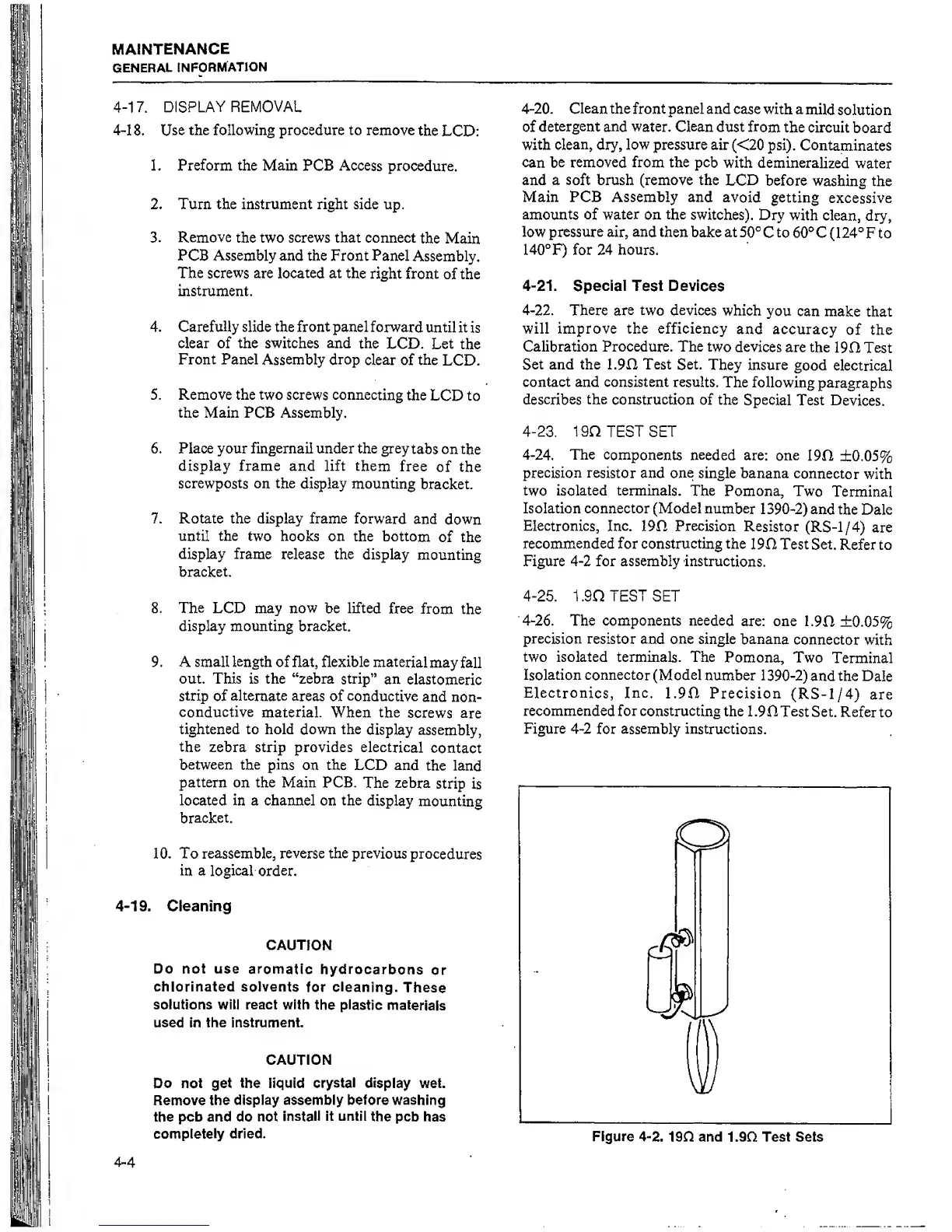

Figure 4-2.

190 and 1.90 Test

Sets

Loading...

Loading...