12

Installation and Operation Manual

SystemsSystems

2001 and 2002

The hose from the CAL/FLUSH port may have a

lower pressure rating since it is plumbed to the

atmosphere and will not receive high pressures.

This hose is used for calibrating the foam pump,

pumping the concentrate into a container to

empty the tank or to assist in priming of the

foam pump. The hose from the CAL/FLUSH

port must be long enough to reach a container

outside the truck. This hose must be coiled for

storage when not in use.

D. LINE STRAINER

The line strainer that is provided with the

FoamPro unit has

3

/4 inch NPT female threaded

ports and is to be installed on the inlet port side

of the foam pump. The hose from the foam tank

should have adequate wall stiffness to withstand

the vacuum of the foam pump while it is

operating (23 in. [584 mm] Hg and 50 psi

[3 BAR]).

NOTE: If a pressurized water flush from one of

the discharges is incorporated, the plumbing and

line strainer exposed to this pressure must be

rated at or above the operating pressure of all

other discharge plumbing components. (400 psi

[28 BAR] minimum) (600 psi [41 BAR] for

2002HP models).

E. FLOWMETER(S)

The FoamPro System 2001 and 2002 are

designed to accept flow reading signals from the

FoamPro paddlewheel style flowmeter.

Proper flowmeter sizing is critical to system

accuracy. Select a flowmeter size based on

actual flows required, not standard pipe sizes.

Refer to the installation drawing at the end of

this manual (Page 39) for proper flowmeter sizing.

The flowmeters require that the amount of

turbulence in the pipe being monitored is as low

as possible. Excessive turbulence produces

unstable and inaccurate flow readings. The

following installation guidelines will help attain

the best readings and maintain accuracy of the

FoamPro system.

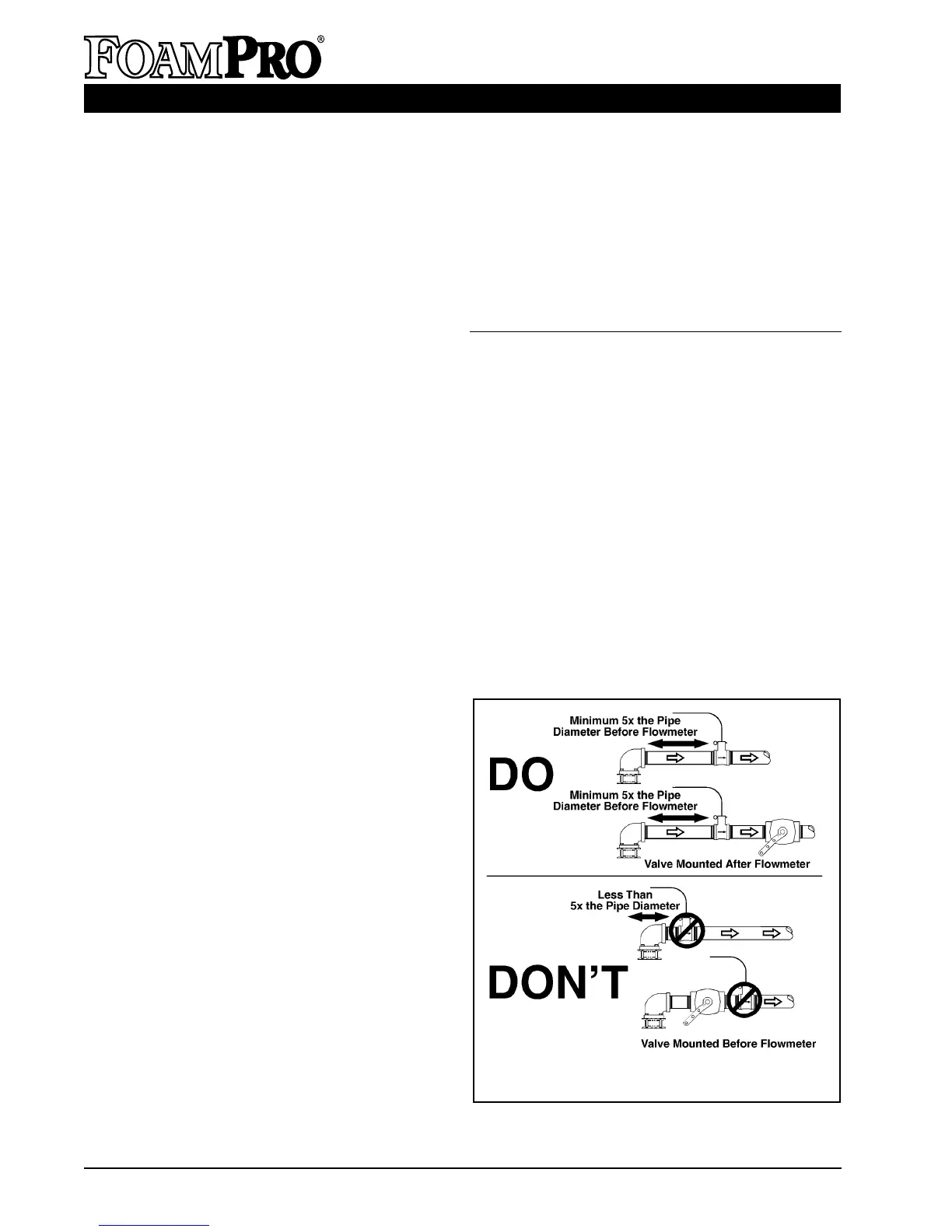

Figure 7. Flowmeter Placement

a. A minimum 5 times the pipe diameter of

straight run pipe without any fittings is

necessary upstream of the flowmeter.

10 times is better — the longer the straight

run, the lower the turbulence. Here are

some examples of required straight run:

Pipe Recommended

Size Straight Run Pipe

1-

1

/2 in. [38 mm].... 7-

1

/2 to 15 in. [191 to 381 mm]

2 in. [50 mm] ........ 10 to 20 in. [254 to 508 mm]

2-

1

/2 in. [64 mm].... 12-

1

/2 to 25 in. [317 to 635 mm]

3 in. [76 mm] ........ 15 to 30 in. [381 to 762 mm]

4 in. [100 mm] ...... 20 to 40 in. [511 to 1016 mm]

b. The downstream plumbing of the flowmeter

is not as critical; but again, straight runs

without fittings help maintain accurate flow

readings.

c. Do not mount a flowmeter directly after

an elbow or valve. Valves create severe

turbulence when they are “gated-down”.

d. Try to mount the flowmeters in a position

that is accessible for routine inspection and

maintenance.

Loading...

Loading...