13

Installation and Operation Manual

SystemsSystems

2001 and 2002

Injector Above

Horizontal Plane

DO

DON'T

Injector Below

Horizontal Plane

INJECTOR ABOVE

HORIZONTAL PLANE

DO

INJECTOR BELOW

HORIZONTAL PLANE

FOAMPRO PADDLEWHEEL

FLOWMETERS

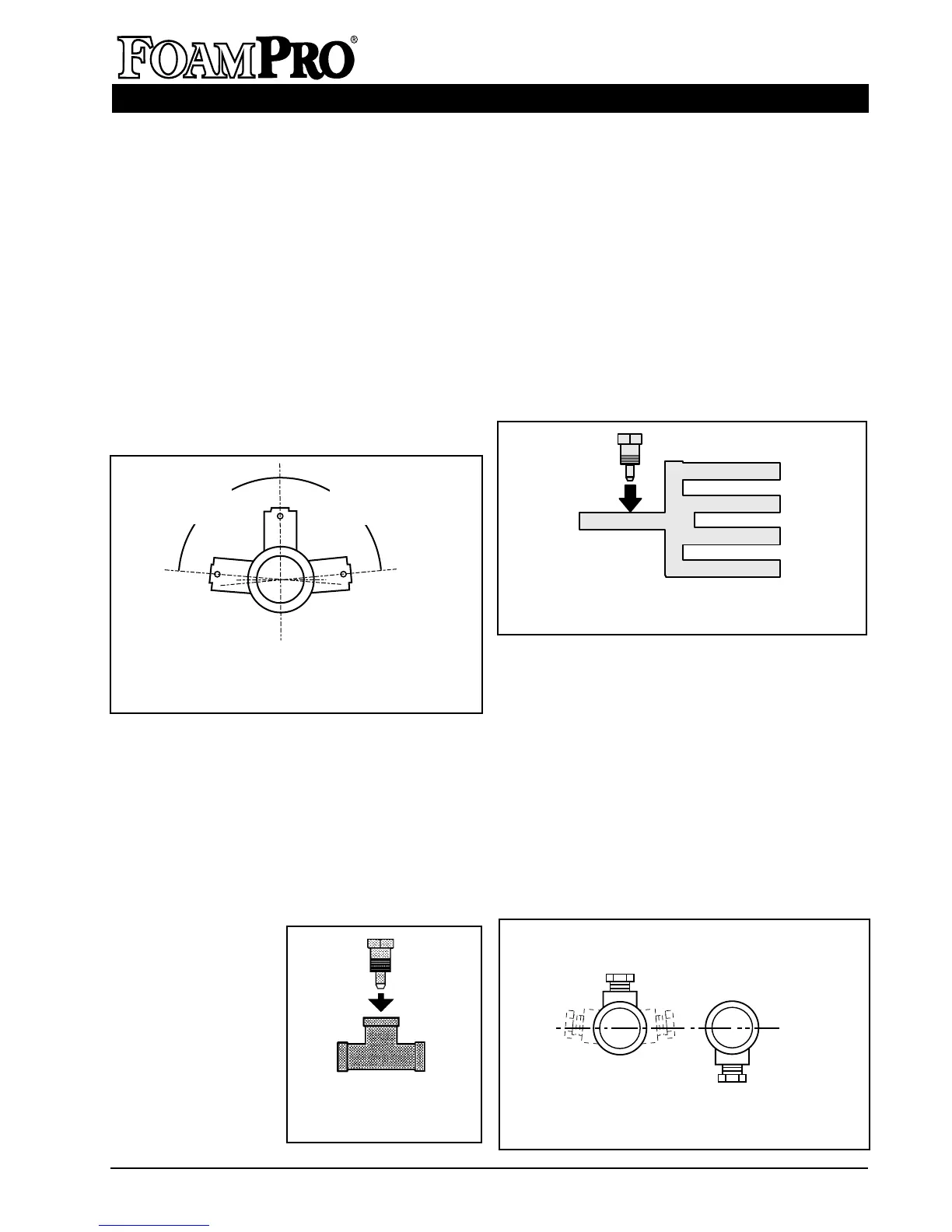

The FoamPro paddlewheel style flowmeter

fittings are specially designed tees that make

inspection and maintenance of the flow sensor

easy. The threads of the tees are NPT. In

horizontal runs the tees should be mounted as

close to upright as possible within the range

shown in Figure 8.

With the use of a MultiFlo interface, two to four

flowmeters may be monitored simultaneously.

A single injection point that will supply foam

agent to all foam discharge outlets is required.

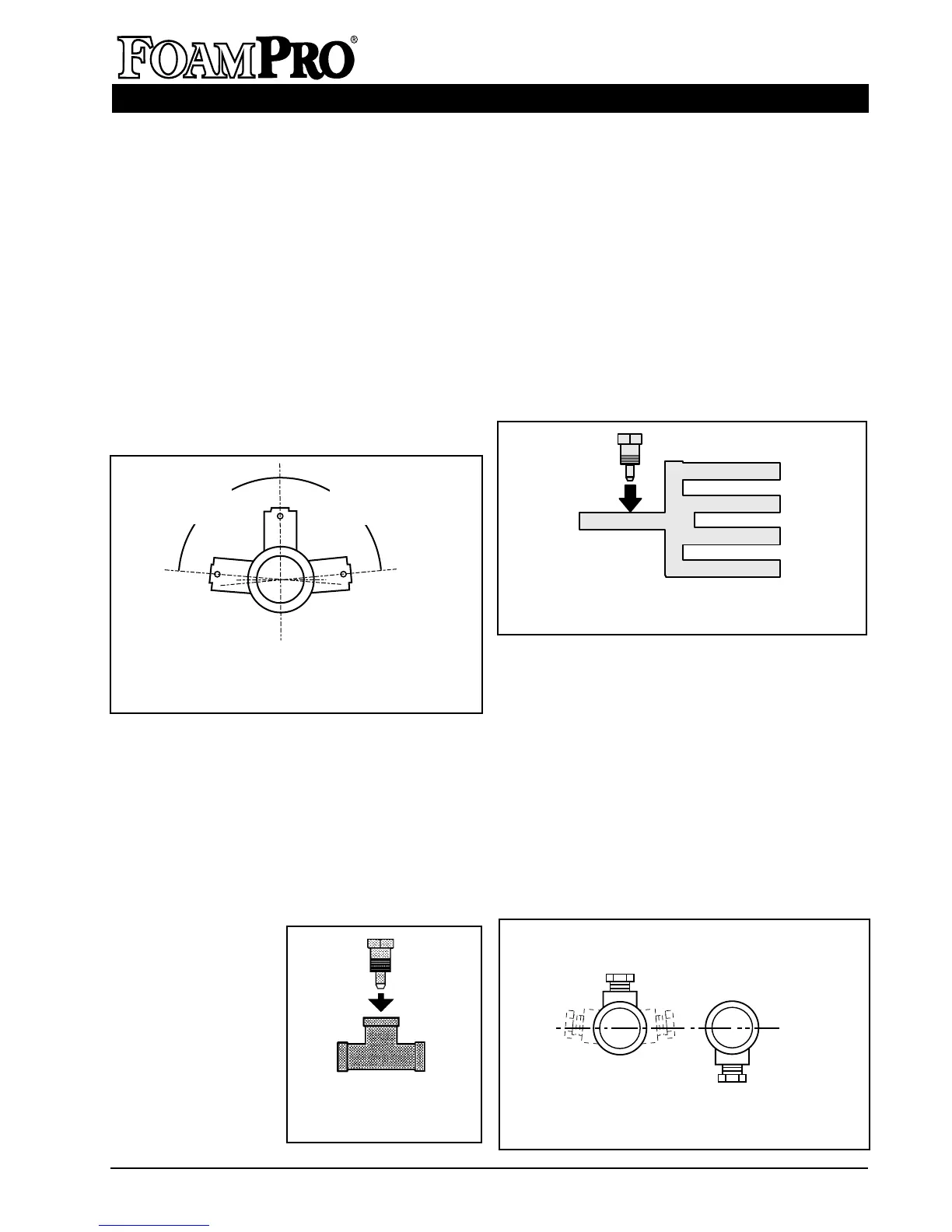

F. INJECTOR FITTING

The brass injector fitting ensures foam

concentrate is injected into the center of the

water flow for better mixing. It is designed to fit

into a 1 inch NPT threaded connection on a pipe

tee that is installed in the discharge piping of the

fire pump (See Figure 9). The inlet of the fitting

is

1

/2 inch NPT female thread and the outer

threads are 1 inch NPT. The injector may also

be inserted into a weld

fitting with 1 inch NPT

female threads. It

MUST be mounted in

a place that is

common to all

discharges which

require foam

capability. This fitting

is not used if using a

FoamPro Main Waterway Check Valve. A

separate injection point is not possible for each

discharge. If multiple flowmeters are used, the

injector must be installed before the flow meters

at the inlet to their common manifold (See

Figure 10).

Most foam concentrates by nature mix with

water very quickly, so each discharge from a

manifold will receive equal concentrations if the

manifold is properly designed and installed.

G. CHECK VALVES

A

1

/2 inch NPT check valve meets NFPA

requirements for a non-return device in the

foam injection system. To prevent foam

concentrate flow from the foam concentrate tank

due to static head pressure, the foam

concentrate check valve shall have a 4 to 6 psi

[0.1 to 0.3 BAR] cracking pressure and shall be

capable of withstanding the pressures that will

be generated in the foam injection line. It is

always a good idea to inject foam at a horizontal

or higher angle to allow water to drain away

Figure 9. Injector

Fitting Installation

Figure 10. Injector Fitting Placement for

Multiple Discharges

Figure 11. Foam Injector Position

DON’T

Figure 8. Flowmeter Position Range

TEE SHOWN WITHOUT

SENSOR INSTALLED

85°

Max.

85°

Max.

Injector

Fitting

Loading...

Loading...