14

Installation and Operation Manual

SystemsSystems

2001 and 2002

from the check valve (see Figure 11).

This will avoid sediment deposits or the

formation of an ice plug.

The check valve in the water way is required to

keep foam solution out of the main pump and

allow pump priming without drawing foam into

the piping. See Figure 12.

H. DRAIN LINES

On apparatus with multiple drain lines, the

drains from the foam solution discharge line

should not be piped into a multi drain system

before the check valves. The standard multi

drain system from most manufacturers will allow

cross talk between the drain lines and the

apparatus water tank, resulting in contamination

of the water tank with foam. A separate drain

system should be provided for the foam solution

piping to prevent contamination of the water

tank and fire pump.

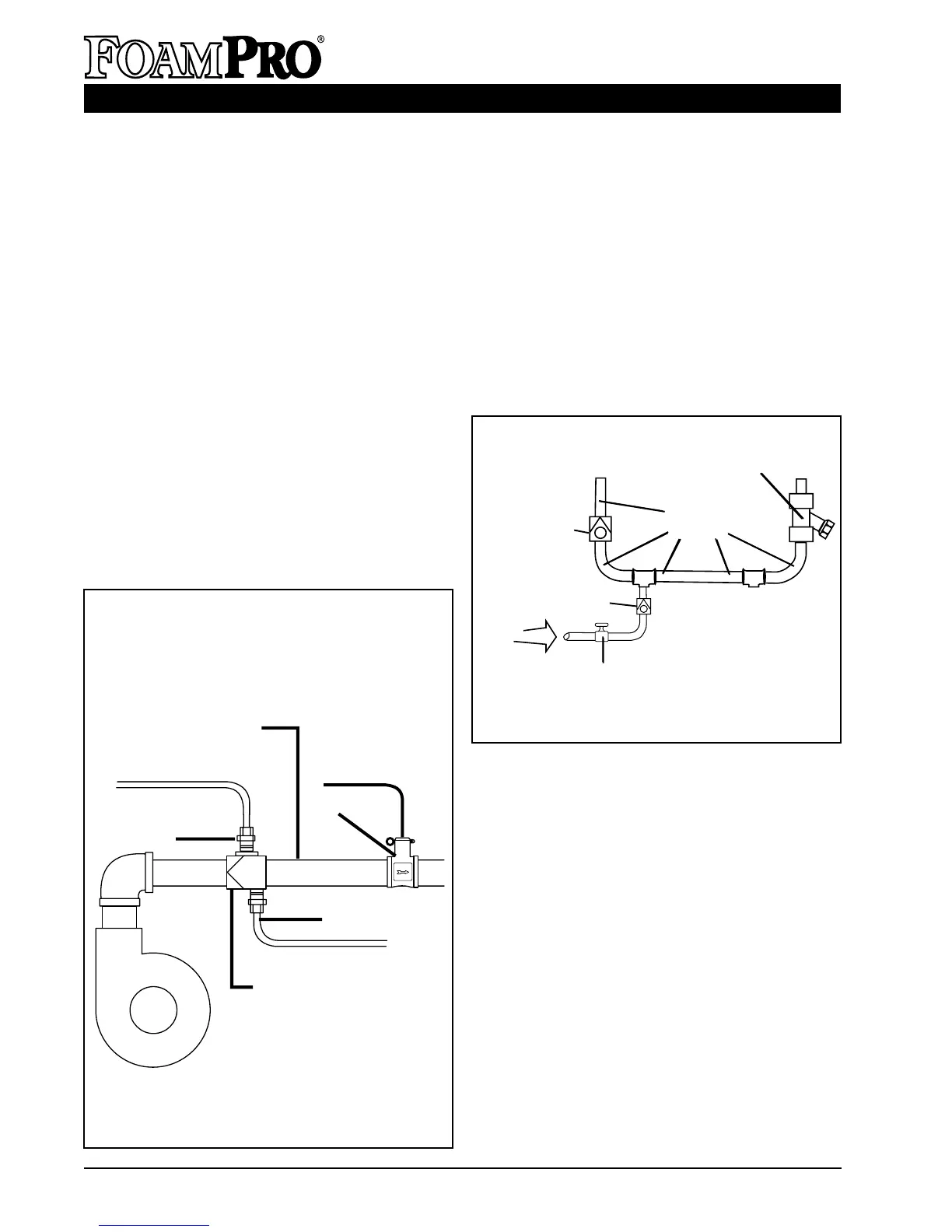

Figure 12. Recommended

Midship Pump Installation

I. FLUSHING SYSTEM

Depending on the corrosiveness of the foam

concentrates to be used, a flushing system may

be required in the foam concentrate injection

system. Generally, all Class B foam

concentrates must be flushed from the system

after use. Most Class A foam concentrates are

less corrosive and therefore may not require

flushing. Fig. 12-4 is a recommended diagram

for a flush circuit. When a dual tank system is

installed on the apparatus, provision for flushing

the foam concentrate injection system is built

into the dual tank selector system.

Minimum Length of

Nipple for 2-1/2''

[158.75 mm] Pipe is

12-1/2"[317.50 mm].

Refer to the Table on

Page 12 for the

recommended Nipple

lengths for different

pipe sizes.

Main Waterway

Check Valve

Drain Line

Check Valve

Injection Port

Drain Port

Flowmeter

From Foam

Tank

Foam Strainer

Mounted On Foam

Pump Inlet

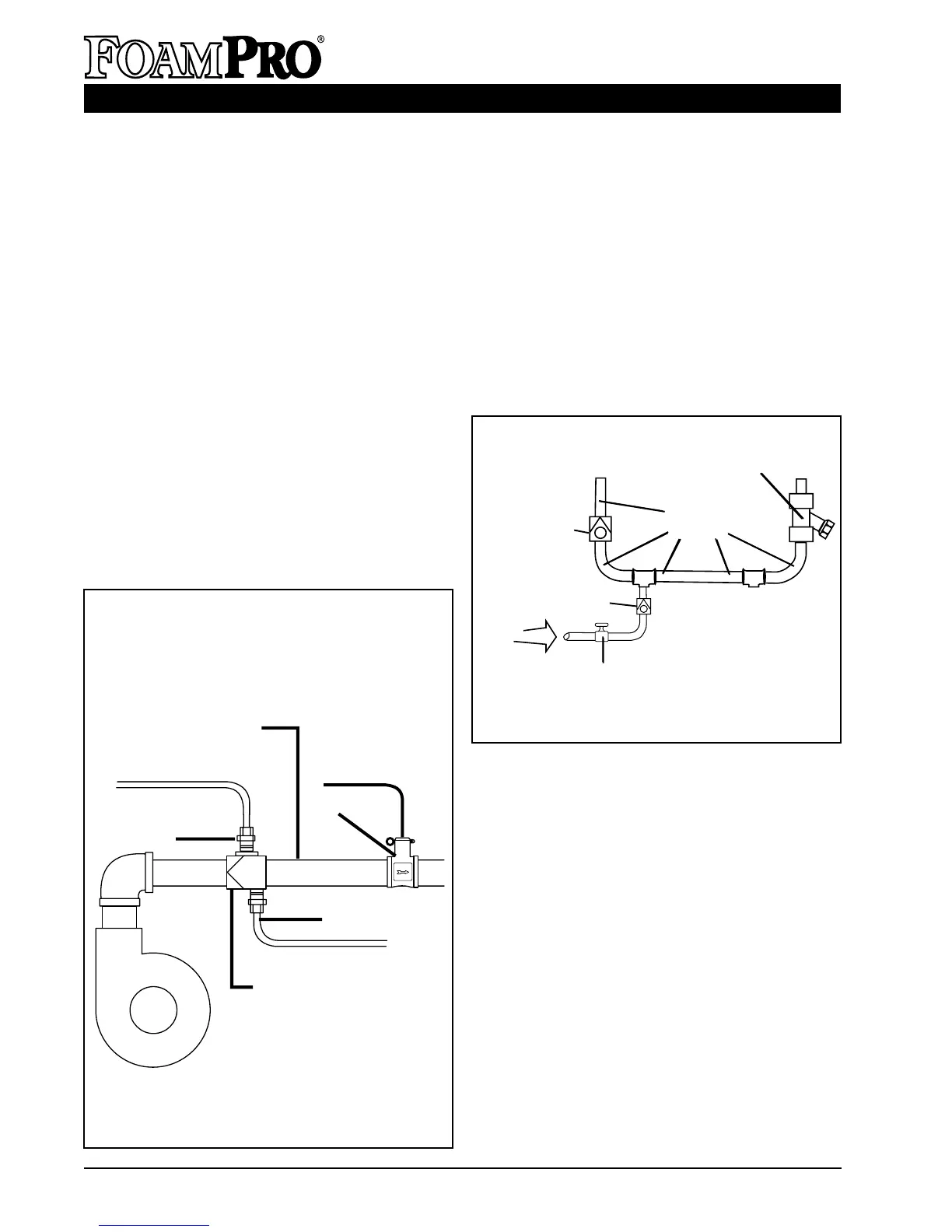

3/4 IN. ID

Hose

Check

Valve

Check

Valve

From

Fire

Pump

Flush Water

Shut-Off Valve

Figure 12-4

Foam Concentrate Flushing System Diagram

Flushing Foam Pumps

When returning the apparatus to ready condition after

foam operations, the FoamPro foam pumps should be

flushed. The following procedures can be used to flush

the foam pumps. Refer to Figure 12-4 and do the

following:

1. Energize apparatus and establish water flow

through foam solution discharge.

2. Close foam concentrate tank shut-off valve and

open flush water supply valve.

3. Energize FoamPro 2000 and allow electric motor

driven foam pump to run until discharge is clear.

4. Shut off FoamPro 2000 system by depressing the

FOAM button on the Digital Display Control Module.

Close flushing water supply valve.

5. Close foam solution discharge and shut down

apparatus.

6. Open foam concentrate tank shut-off valve.

7. Perform required maintenance checks on the

FoamPro 2000.

Loading...

Loading...