16

Installation and Operation Manual

SystemsSystems

2001 and 2002

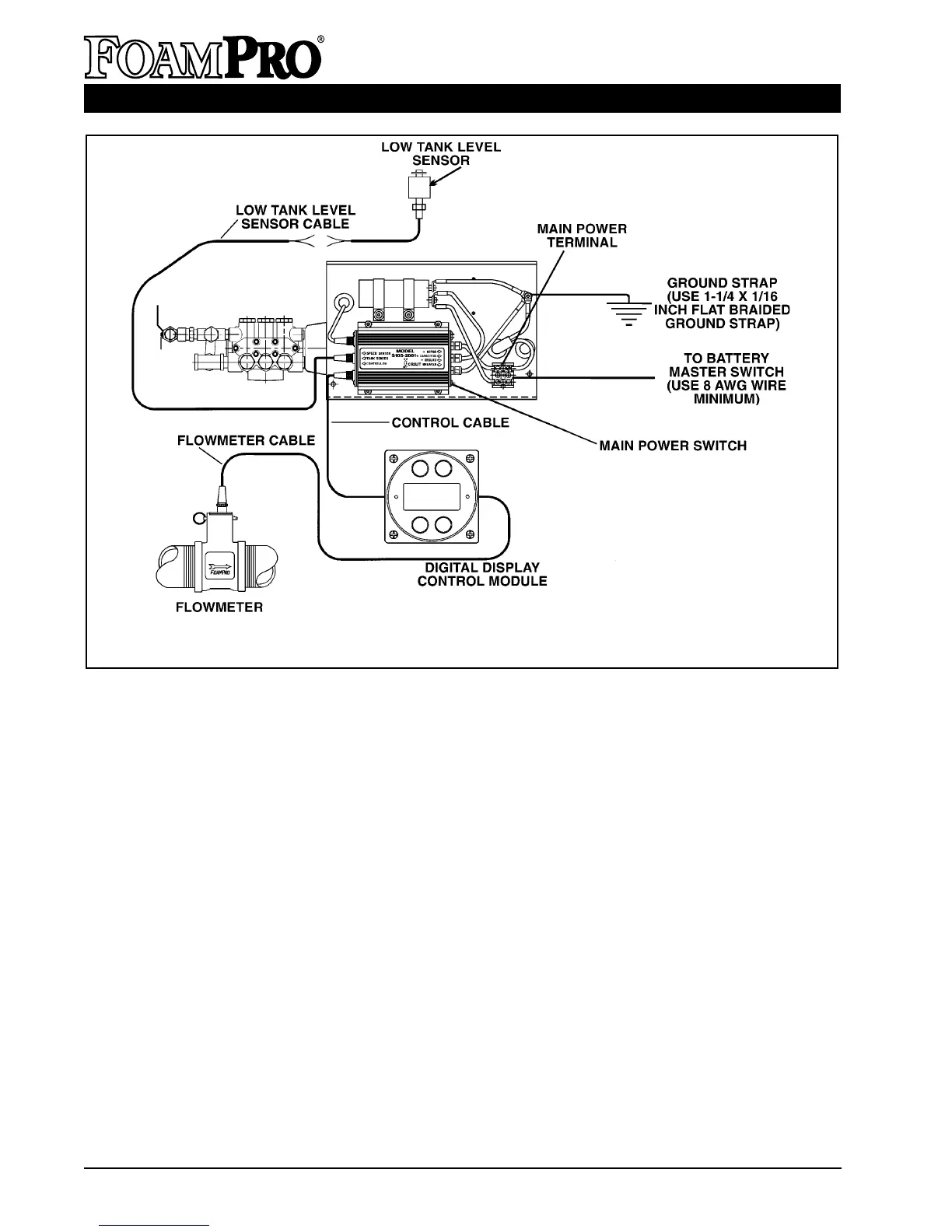

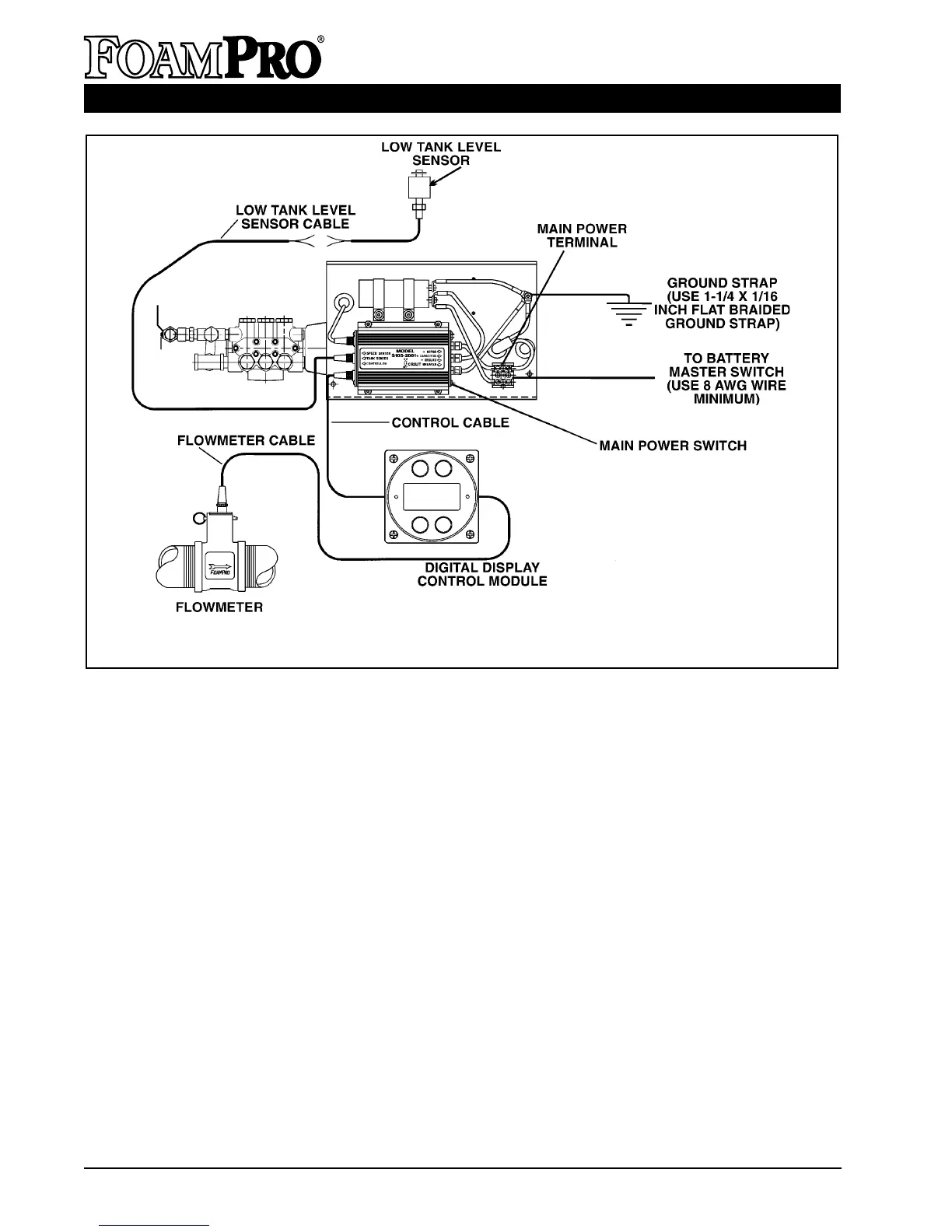

Figure 14. FoamPro 2001 Electrical Wiring Diagram

• Do not mount radio transmitter or transmitter

cables in direct or close contact with the

FoamPro unit.

• Use care when installing molded cables.

Count pins or check color codes before

connecting. Bent pins caused by improper

hookup can prevent proper operation even

when cables are reattached properly.

• Before connecting the molded cables,

inspect the yellow seal washer in the female

connector. If the seal washer is missing or

damaged, water can enter the connector and

cause corrosion of the pins and terminals

that will cause system failure.

• CAUTION: The cables shipped with each

FoamPro unit are tested at the factory with

that unit. Improper handling and forcing

connections can damage these cables,

which could result in other system damage.

• CAUTION: Always disconnect the ground

straps and control cables from the Digital

Display Control Module or other FoamPro

equipment before electric arc welding at any

point on the apparatus. Failure to do so will

result in a power surge through the unit that

could cause irreparable damage to the

display or other system components.

A. DIGITAL DISPLAY/CONTROL MODULE

The Digital Display Control Module is designed

to be mounted in the operator panel of the

apparatus. The cutout that will be needed in the

operator panel is a 3-

7

/8 inch [98 mm] diameter

hole (the same as a 3-

1

/2 inch [89 mm] pressure

gauge). The display is secured with four #10

socket head screws in the four holes in the face

(See Page 40 for a mounting template). The

display requires 5 inches [127 mm] minimum

from the back of the operator panel to clear

HYPRO

Loading...

Loading...