17

Installation and Operation Manual

SystemsSystems

2001 and 2002

Figure 16. Motor Driver Box Connections

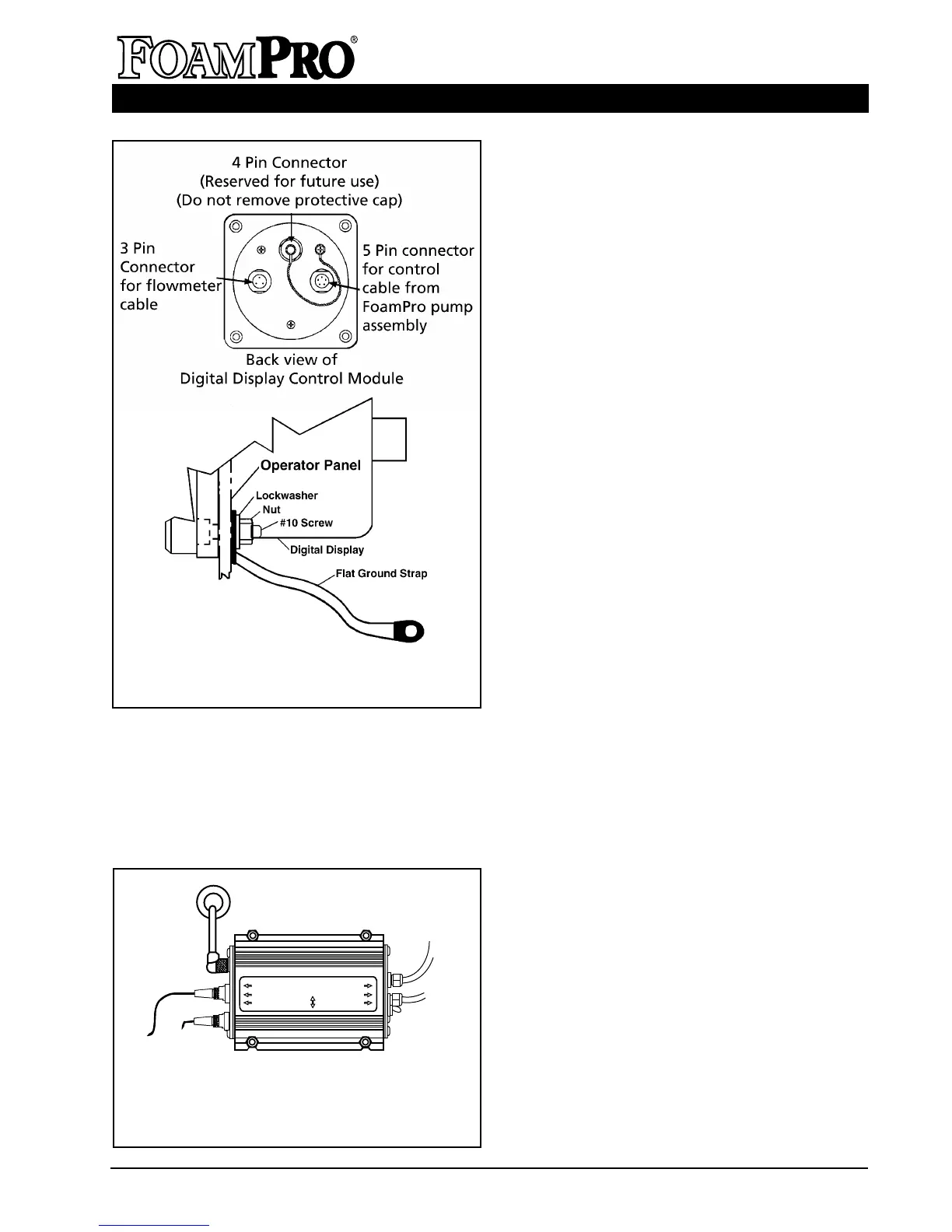

Figure 15. Digital Display Control

Module Cable Connections and

Grounding

SPEED SENSOR

TANK SENSOR

CONTROLLER

CAPACITOR

DIODE

CIRCUIT BREAKER

ON

OFF

+

+

* Connections to be made

during installation.

*

*

wires and connectors. Make sure there is

enough clearance behind the operator’s panel

for the cables. Once the Digital Display Control

Module is mounted, connect the control cable

(red coded cable end) from the motor driver box

terminal to the 5 pin connector on the back of

the Digital Display Control Module (see

Figure 15). A color coded decal on the motor

driver box identifies each cable connection (see

Figure 16).

NOTE: Make sure the panel where the Digital

Display Control Module is mounted has an

adequate ground. For stainless steel and vinyl

coated panels, a flat ground strap must be

attached from one of the four screws holding

the Digital Display Control Module in place, to

the frame of the fire truck to ensure adequate

grounding (see Figure 15).

B. FLOWMETER(s) CONNECTIONS

FOAMPRO FLOWMETER

If a single FoamPro paddlewheel type flowmeter

is to be used, a molded cable that connects

from the flowmeter to the 3 pin connector on the

Digital Display Control Module is supplied.

MULTIFLO FLOWMETER INTERFACE

MODULES

See the instructions supplied with the MultiFlo

interface for installations requiring multiple

Foampro flowmeters. Figure 17 shows the

interconnection of the flowmeters with the

Digital Display Control Module.

C. FOAM TANK CONNECTIONS

The foam tank low level sensor must be

mounted into the bottom of the foam tank to

monitor low foam concentrate level. The switch

has

1

/8 inch NPT threads. Mount the sensor in

the bottom of the foam tank in an upright

position. Use suitable sealant to prevent

concentrate leakage. There must be space

under the tank for the cable to be routed to the

pump base assembly (See Figure 18). Be sure

not to remove the float from the shaft on the

sensor assembly. If installed in the reverse

position, "

LO CON

" and "

NO CON

" will appear

on the Digital Display Control Module, and the

system will automatically shut down after two

minutes, even if there is foam in the tank.

When the bottom of the foam tank is not

accessible, the low level sensor float switch can

Loading...

Loading...