18

Installation and Operation Manual

SystemsSystems

2001 and 2002

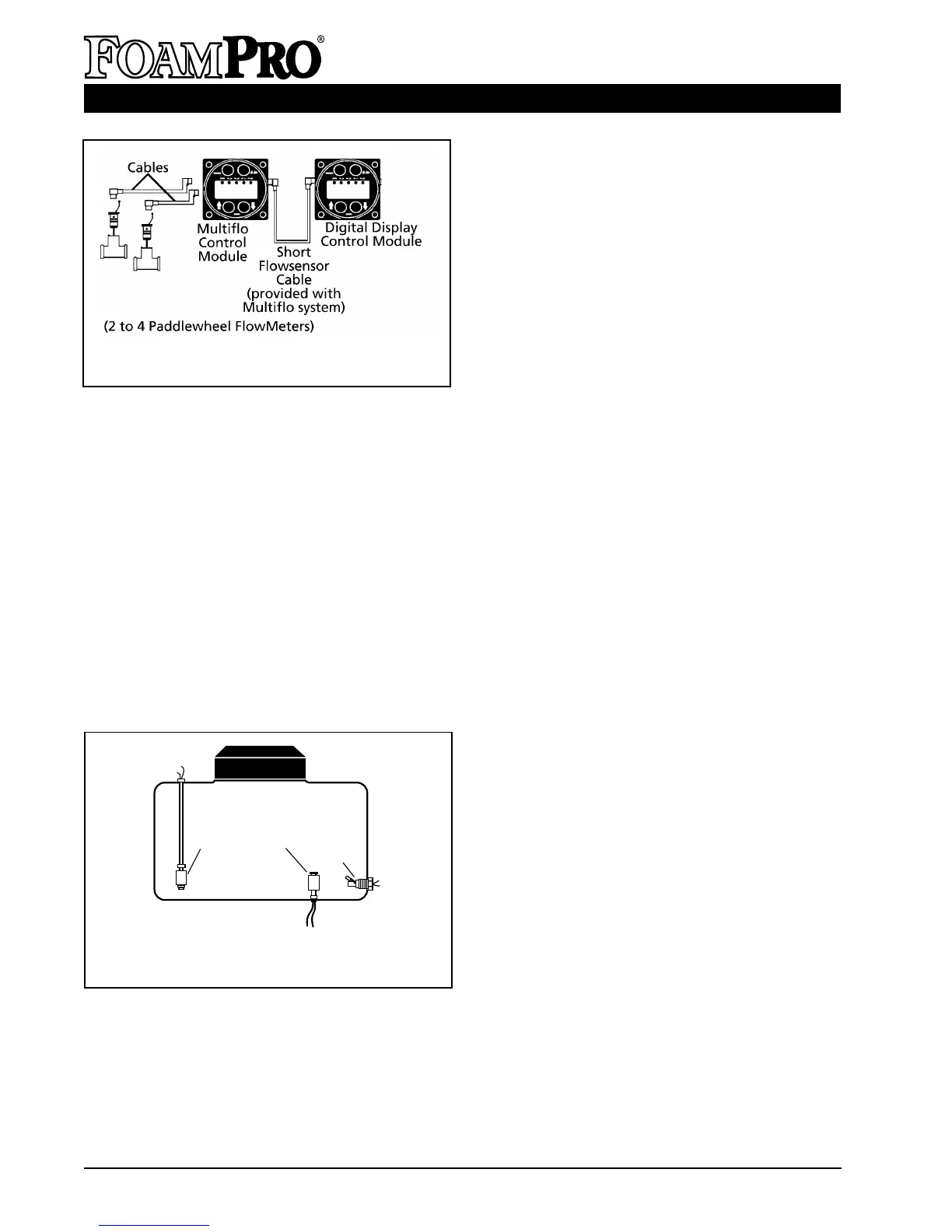

Figure 18. Foam Tank Low Level Sensor

Mounting Options

be hung from a long nipple attached to the top

of the tank. The nipple should be rigid enough

to withstand the force of sloshing foam when the

vehicle is in motion. Make sure the low level

sensor does not contact the side of the foam

tank when the vehicle is in motion (See Figure

18). Since wire connections must be made

inside the nipple, a

3

/8 inch NPT nipple with

3

/8

by

1

/8 inch NPT reducer at the lower end is the

minimum size recommended.

CAUTION: The foam tank low level sensor must

be utilized to protect the foam pump from dry

running. Failure to do so will void the warranty.

Connect the sensor wires to the low tank sensor

cable (blue coded cable ends). The low tank

switch sensor cable may be shortened or

lengthened (use 18-22 AWG). It has pigtails at

one end and is not polarity sensitive. Connect

the other cable end to the motor driver box on

the foam pump/motor base assembly (see

Figure 16).

Check low level sensor operation after

installation using a powered test light. With no

foam in the tank, the light should be on. If this

is not the case, remove the clip from the end of

the sensor. Remove the float and reinstall 180

o

out of position. Reinstall clip.

A side mount low tank sensor is available to be

used if both the top and bottom of the tank is

not accessible (See Figure 18). The side mount

low tank sensor has

1

/2 inch NPT threads and

the center of the switch must be located

approximately 2 inches [51 mm] from the bottom

of the foam tank with the float positioned on top

of the switch to move up and down.

NOTE: When the side mount low tank sensor

senses a low concentrate condition, the

system will operate for two minutes unless

the foam concentrate level is restored. If the

foam concentrate level is not restored, the

system will shut down after two minutes.

When locating the side mount low tank level

switch on the foam tank, sufficient foam

volume must be present for two minutes of

operation. This determination will be made

using the most frequent foam concentrate

injection rate and water flow.

The side mount low tank sensor must be sealed

with a suitable sealant to prevent concentrate

leakage. After installation, check operation of

the side mount low tank sensor with a powered

test light. With no foam in the tank, the light

should be on. If light does not come on, rotate

the side mount low tank sensor until the test

light is on. The float should be allowed to swing

up and down freely.

D. DC MOTOR

Provide adequate electrical power (see the

listing on Page 15) from the battery. Use

8 AWG minimum wire directly to the battery or

battery switch. Long wire runs may require

6 AWG wire for proper operation.

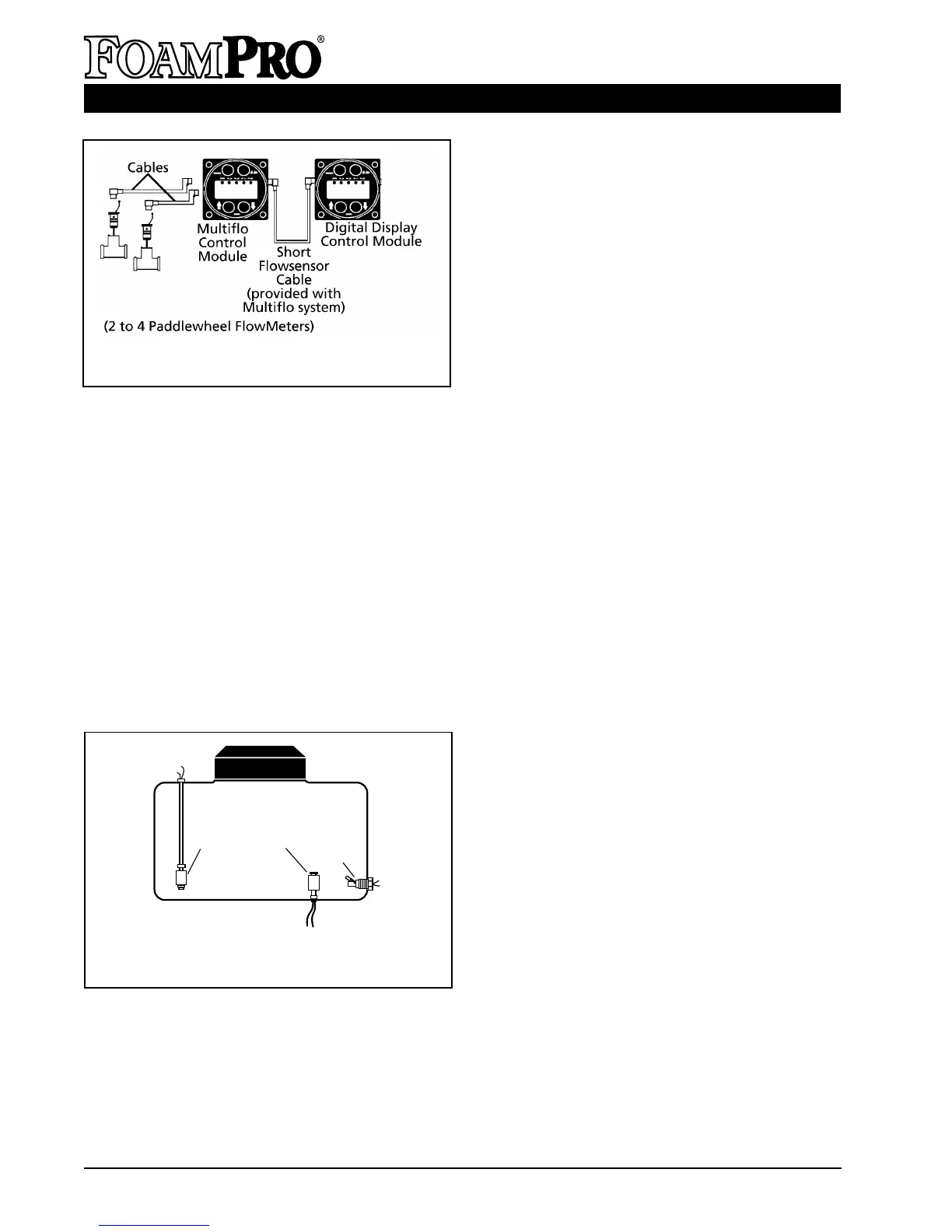

Figure 17. Multiflo and Flowmeter

Connections

Top Mount

Low Tank Sensor

BOTTOM MOUNT

Side Mount

Tank Sensor

(OPTIONAL)

Loading...

Loading...