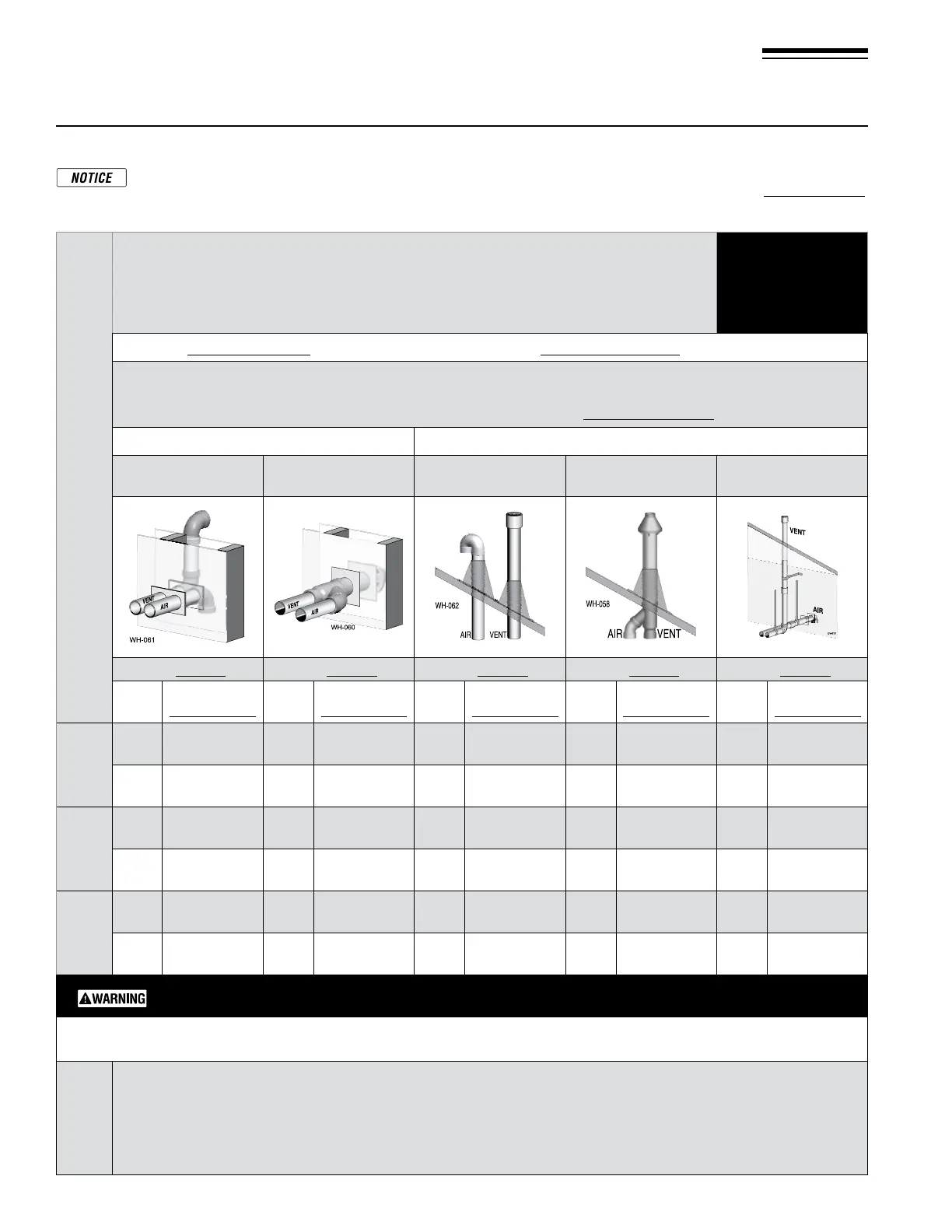

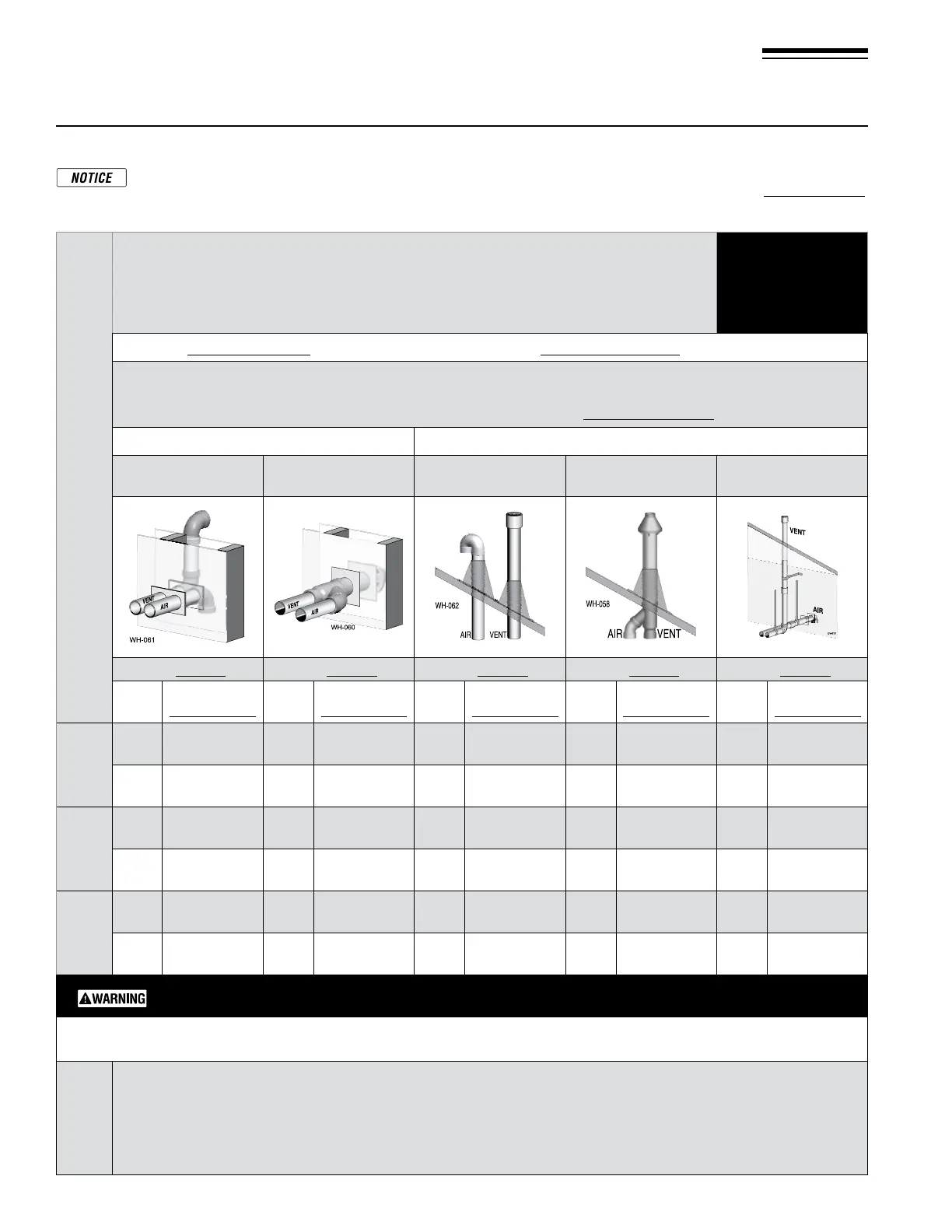

Figure 20 Venting and air piping — DIRECT VENT ONLY — OPTIONS and PIPING LIMITS

e table below lists the acceptable vent/air pipe terminations described in this manual. Follow all instructions provided to install the

vent/air system. NOT SHOWN below, but also approved, are the polypropylene piping and terminations listed in Figure21,page17.

For these applications, use ONLY the manufacturers’ parts listed and follow all instructions provided by the pipe manufacturer.

Part number 550-142-950/0122

16

FreeStyle

®

series

2

wall mount gas-fired water boiler – boiler manual

6 Venting/air piping — general continued

FreeStyle® Model

Maximum vent and air pipe length =

100 feet for all applications

(Minimum length for all applications is 2 feet equivalent plus termination)

(All applications include allowance for the termination ttings plus one elbow in air piping and one elbow in vent piping)

USE

SWEEP

ELBOWS

ONLY

See Figure 21, page 17 for material specifications | See Figure 164, page 121 for part/kit numbers

Vent and air pipe sizes:

Maximum vent lengths apply for 3” vent and air pipe.

Boilers will derate as vent/air pipe length increases —

*

see Rating data on Figure 178, page 135 for derate amounts.

SIDEWALL termination VERTICAL termination

Separate pipes

[Note 1]

PVC or PP Concentric

[Note 1]

Separate pipes

[Note 1]

PVC or PP Concentric

[Note 1]

Vertical vent,

Side Air [Note 1]

See page21 See page23 See page25 See page27 See page29

Size,

inches

Materials

Fig. 21,page17

Size,

inches

Materials

Fig. 21,page17

Size,

inches

Materials

Fig. 21,page17

Size,

inches

Materials

Fig. 21,page17

Size,

inches

Materials

Fig. 21,page17

80

2

PVC/PVC-DWV

CPVC, PP, SS

2

PVC/PVC-DWV

CPVC, PP, SS

2

PVC/PVC-DWV

CPVC, PP, SS

2

PVC/PVC-DWV

CPVC, PP, SS

2

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

120

2

PVC/PVC-DWV

CPVC, PP, SS

2

PVC/PVC-DWV

CPVC, PP, SS

2

PVC/PVC-DWV

CPVC, PP, SS

2

PVC/PVC-DWV

CPVC, PP, SS

2

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

155

2

CPVC, PP, SS

2

--------

2

CPVC, PP, SS

2

--------

2

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

3

PVC/PVC-DWV

CPVC, PP, SS

All elbows in vent and air piping must be sweep elbows ONLY. DO NOT use short-radius elbows.

Equivalent feet for elbows (USE SWEEP ELBOWS ONLY) —

deduct from max equivalent length of piping (does not apply to termination ttings).

• 7 feet per for each additional 90° sweep elbow or 45° elbow —

If piping contains more than 1 elbow in air or vent piping, other than termination ttings.

Note 1:

ABS may be used for intake air.

Material abbreviations: PP = polypropylene, SS = AL29-4C stainless steel.

If using stainless pipe, provide adapters for terminations, if required.

IPEX 3” PVC concentric vent kits can be used with standard PVC pipe, ttings and cement (ANSI/ASTM D1785) except if ULC S636 compliance

is required. For ULC S636 compliance, all pipe, ttings and cement must be IPEX System 636. For UL 1738 compliance all pipe, ttings and

cement must be IPEX System 1738. If using IPEX kits, use only IPEX product code 196006 for 3” venting.

Loading...

Loading...