Inspect/ll condensate system

Inspect/check condensate lines and ttings

1. Inspect the condensate drain line, condensate PVC ttings and

condensate trap. (See page49 for component locations.)

Fill condensate trap with water

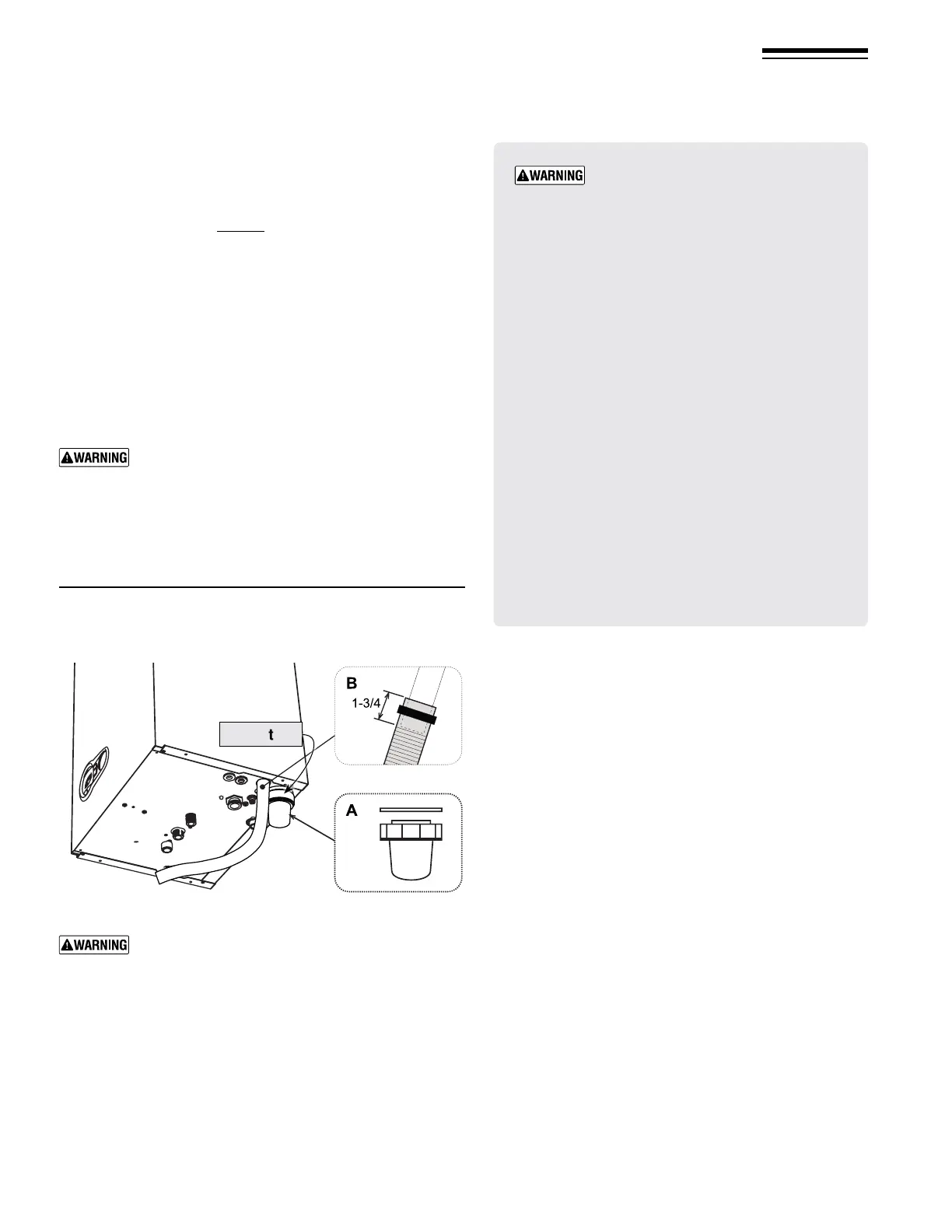

1. Loosen the nut that secures the condensate trap body to the

boiler condensate connection (see Figure103). Pull the trap

down to disengage from heat exchanger. \Pull the trap body

forward enough to allow pouring water into the top of the trap.

2. Fill the trap with fresh water until water begins to run into the

condensate drain tube.

3. Reattach the trap body by sliding onto the boiler condensate

outlet, then retightening the trap body nut.

e condensate trap must be lled with water during

all times of boiler operation to avoid ue gas emission

from the condensate drain line. Failure to ll the trap

could result in severe personal injury or death.

Nut

Figure 103 Disconnect condensate trap assembly to ll

trap body with water

If it is suspected that the condensate drain con-

nection is or was blocked, then boiler components

like the gas valve, blower venturi, igniter and heat

exchanger need to be inspected. Check for damages

occurring from water accumulation in this cabinet.

Any damaged components need to be replaced.

Failure to replace water damaged components could

result in severe personal injury or death.

Part number 550-142-950/0122

78

FreeStyle

®

series

2

wall mount gas-fired water boiler – boiler manual

33 Startup — nal checks

Check for gas leaks

Before starting the boiler, and during initial operation,

use a leak detector or smell near the oor and around

the boiler for gas odorant or any unusual odor. Remove

boiler jacket door and smell the interior of the boiler

jacket.

Do not proceed with startup if there is any

indication of a gas leak. Repair any leak at once

.

DO NOT adjust or attempt to measure gas valve out-

let pressure.

e gas valve is factory-set for the correct

outlet pressure. is setting is suitable for natural gas

and propane, requiring no eld adjustment. Attempting

to alter or measure the gas valve outlet pressure could

result in damage to the valve, causing potential severe

personal injury, death or substantial property damage.

Propane boilers only — Your propane supplier mixes

an odorant with the propane to make its presence de-

tectable. In some instances, the odorant can fade, and

the gas may no longer have an odor. Before startup

(and periodically thereaer), have the propane supplier

verify the correct odorant level in the gas.

Loading...

Loading...