Part number 550-142-950/0122

39

FreeStyle

®

series

2

wall mount gas-fired water boiler – boiler manual

18 Primary/Secondary System Piping

Figure 49 Maximum and minimum ow rates through

boiler heat exchanger

System water piping methods

Primary/secondary piping to boiler

Using primary/secondary piping will provide the most ecient

and reliable operation of the boiler and the heating system.

1. Use information beginning on this page to size pump for

proper ow through the boiler.

2. Reference suggested piping layouts on pages 40-45.

System water piping methods

Near boiler piping

1. Connect boiler to system only as shown in Figure51,page40.

e primary/secondary piping shown ensures the boiler loop

will have sucient ow.

2. Install a system circulator or zone circulators as shown in the

piping diagrams in the Primary/Secondary System Piping

section in this manual. ese circulators must be supplied

by the installer.

System or zone circulators ow rates

1. Size circulators based on the ow rate required to achieve the

temperature drop required. You can closely estimate temper-

ature rise (or drop) through a circuit by using the following

formula, where TD is temperature rise (or drop), FLOW is

ow rate (in gpm), and BTUH is the heat load for the circuit:

FLOW =

BTUH

—–—–—–—–

TD x 500

Examples:

1. Consider a system loop for a system with total heating load

equal to 143,000 Btuh. e desired temperature drop through

the system piping is 20°F. en the required ow rate is:

FLOW =

143,000

—–—–—–—–

20 x 500

= 14 gpm

SIMPLIFIED:

For 20° temperature drop, FLOW = MBH / 10.

System or zone circulator head requirement

1. e circulator must be capable of delivering the required

ow against the head loss that will occur in the piping.

2. Determine the pipe size needed and the resultant head

loss using accepted engineering methods.

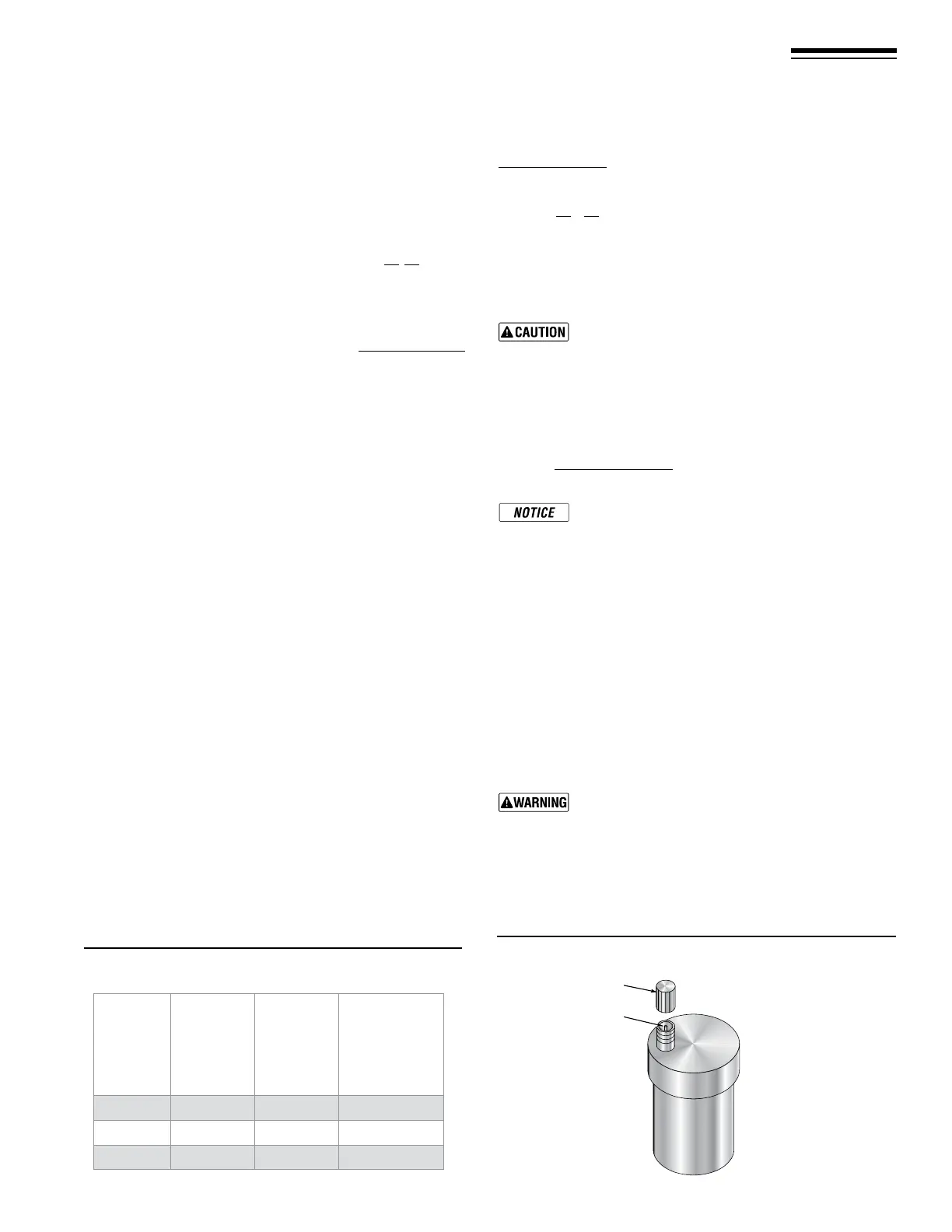

Boiler

Model

MAX

Flow Rate

20° F

temperature

rise

GPM

MIN

Flow Rate

50° F

temperature

rise

GPM

Flow Rate

Delta T1

protection

67° F

temperature

rise

GPM

FS-80 7.9 2.9 2.3

FS-120 12.0 4.3 3.4

FS-155 15.2 6.1 4.5

Expansion Tank Location

Figure51,page40show typical installation of the system expansion

tank. It is highly recommended that you locate the air separator

and expansion tank as shown in the suggested piping drawings

on pages 39 - 41.

Ensure that the expansion tank size will handle boiler and system

water volume and temperature. See tank manufacturer’s instruc-

tions and ratings for details. Additional tanks may be added to

the system if needed to handle the expansion. ese tanks may be

installed by connecting to tees in the system piping.

Undersized expansion tanks cause system water to

be lost from the relief valve and makeup water to be

added through the ll valve. Eventual boiler failure

can result due to excessive make-up water addition.

Always locate the cold-water ll connection at the

expansion tank. Never locate this elsewhere.

Diaphragm- or bladder-type tank:

Refer to Figure 51, page40 for suggested piping when using a

diaphragm- or bladder-type expansion tank.

Diaphragm- or bladder-type expansion tank—

Always check pressure and charge tank with tank

removed from system to be sure reading is accu-

rate. Boiler relief valve is set for 30 PSIG. Operat-

ing pressure of system, aer temperature expansion

above cold ll pressure, should not exceed 24 PSIG

to avoid weeping of relief valve.

Install an automatic air vent on top of the air separator, per separa-

tor manufacturer’s instructions.

Automatic air vents (if used — automatic air

vents must be used with diaghragm-type expansion

tanks only)

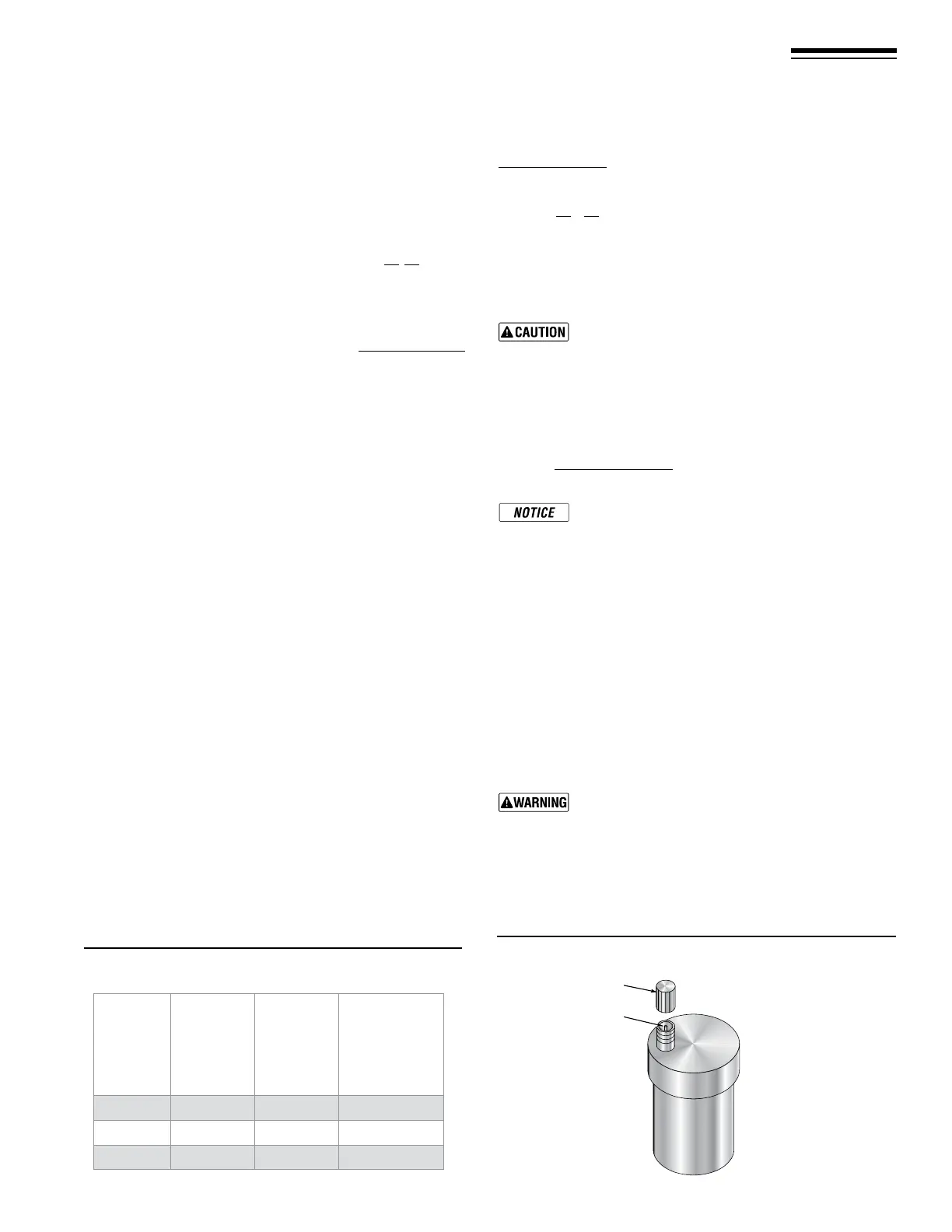

1. Remove the cap from any automatic air vent in the system

and check operation by depressing valve “B” slightly with the

tip of a screwdriver.

Scald hazard — Water from air vent may be very

hot. Avoid contact to prevent possible severe per-

sonal injury.

2. If the air vent valve appears to be working freely and not leak-

ing, replace cap “A”, twisting all the way on.

3. Loosen cap “A” one turn to allow vent to operate.

4. Have vent replaced if it does not operate correctly.

Figure 50 Automatic air vent

Loading...

Loading...