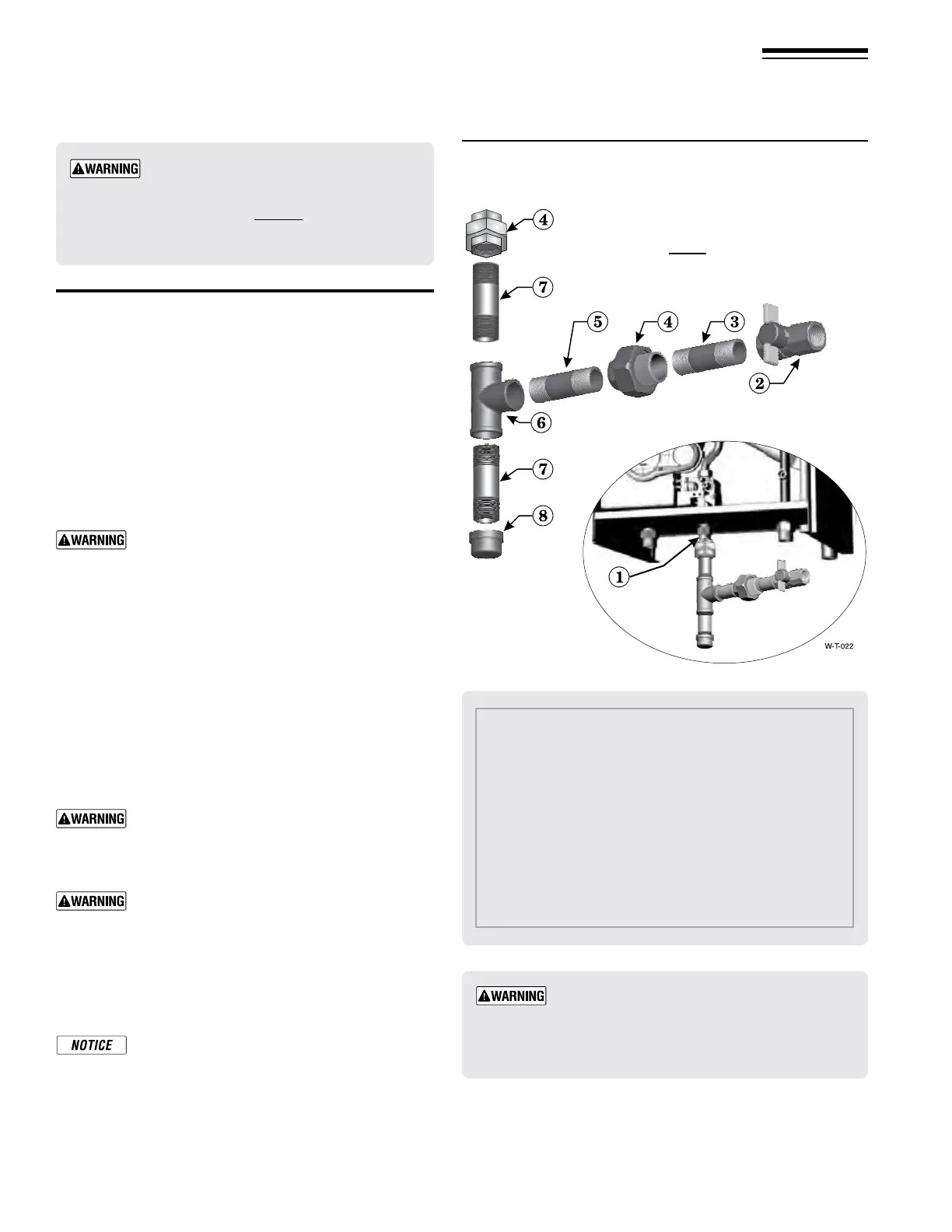

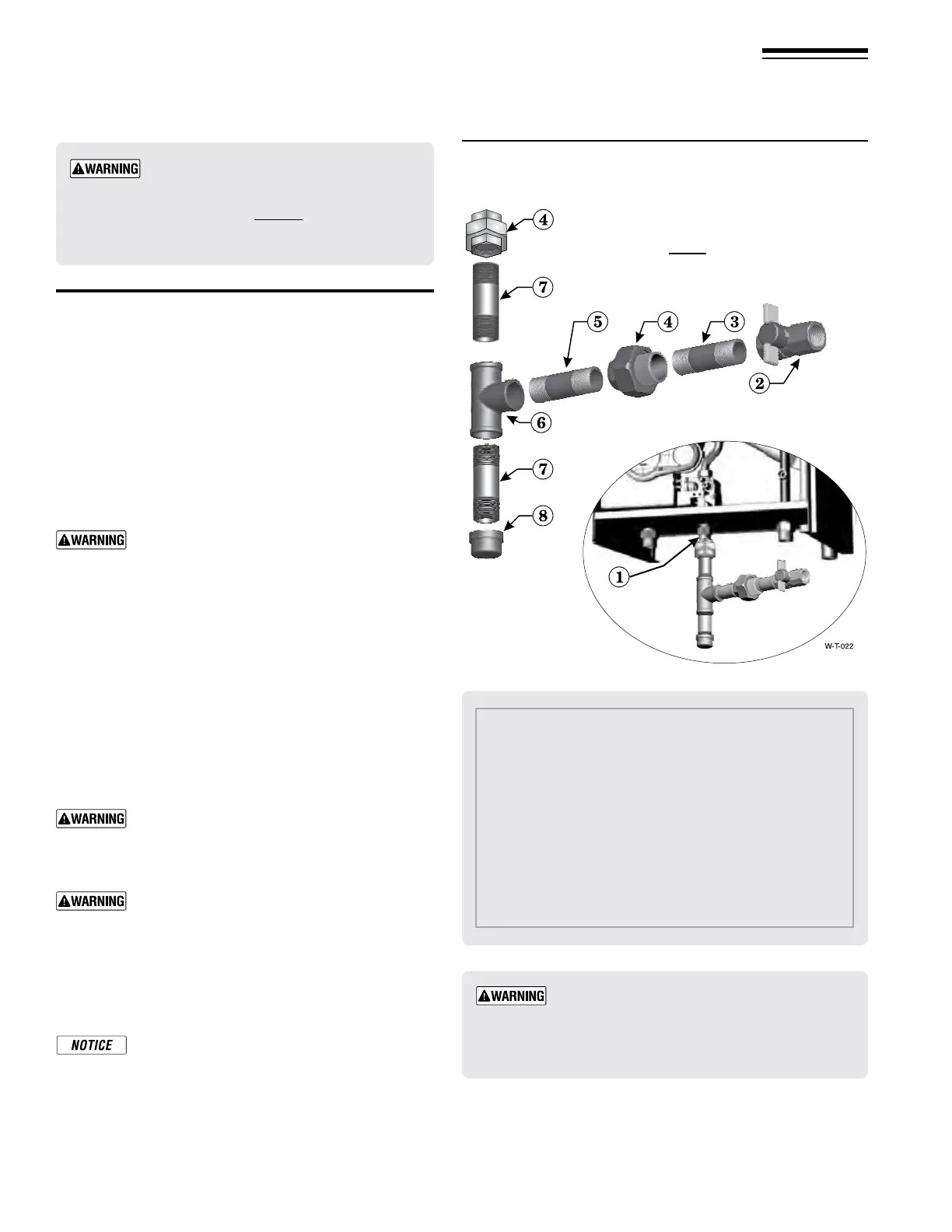

Figure 63 Connect gas supply piping

(Heating Only boiler shown).

Part number 550-142-950/0122

50

FreeStyle

®

series

2

wall mount gas-fired water boiler – boiler manual

21 Gas piping

FreeStyle

®

boilers are shipped ready to re

natural gas ONLY. You must install the pro-

pane venturi if the boiler will be connected

to propane. See page10. Failure to comply

could result in severe personal injury, death

or substantial property damage.

Connecting gas supply piping

1. Remove jacket door and refer to Figure63 to pipe gas to

boiler.

a. Place a pipe wrench on the gas line inside the jacket

when tightening the gas line assembly to the boiler gas

connection (item1).

b. Install steel pipe ttings as shown in Figure63. All

pipe ttings and gas cock are supplied by the installer.

2. Use pipe dope compatible with propane gases. Apply spar-

ingly only to male threads of pipe joints so that pipe dope

does not block gas ow.

Failure to apply pipe dope as detailed above can

result in severe personal injury, death or substan-

tial property damage.

3. Connect gas supply piping to the ½” NPT gas cock for

80/120 boilers and ¾” NPT for 155 boilers (item2).

4. Support gas piping with hangers, not by boiler or its ac-

cessories.

5. Purge all air from gas supply piping.

6. Before placing boiler in operation, check boiler and its gas

connection for leaks.

a. During any pressure testing at less than 13” w.c., close

the gas shuto valve and disconnect system gas piping.

At higher test pressures, disconnect boiler and gas valve

from gas supply piping.

Do not check for gas leaks with an open ame

— use bubble test. Failure to use bubble test or

check for gas leaks can cause severe personal

injury, death or substantial property damage.

DO NOT adjust or attempt to measure gas valve

outlet pressure. e gas valve is factory-set for the

correct outlet pressure. is setting is suitable for

natural gas and propane. Attempting to alter or

measure the gas valve outlet pressure could result

in damage to the valve, causing potential severe

personal injury, death or substantial property

damage.

Flexible appliance gas connectors are NOT rec-

ommended.

Use two wrenches when tightening gas piping at

boiler, using one wrench to prevent the boiler gas

line connection from turning. Failure to support

the boiler gas connection pipe to prevent it from

turning could damage gas line components.

1 Boiler gas supply connection, ½”NPT male for 80/120

boilers and ¾” NPT for 155 boilers.

ALL OF THE FOLLOWING ARE SUPPLIED BY THE INSTALLER:

2 T-handle gas cock, ½” NPT for 80/120 boilers and ¾” NPT for 155

boilers.

3 Nipple, ½” NPT for 80/120 boilers and ¾” NPT for 155 boilers.

4 Unions, ½” NPT for 80/120 boilers and ¾” NPT for 155 boilers.

5 Nipple, ½” NPT for 80/120 boilers and ¾” NPT for 155 boilers.

6 Tee, ½” NPT for 80/120 boilers and ¾” NPT for 155 boilers.

7 Nipple, ½” NPT x 6” for 80/120 boilers and ¾” NPT x 6” for 155

boilers, for drip leg.

8 Cap, ½” NPT for 80/120 boilers and ¾” NPT for 155 boilers.

Union or Coupling must be used.

Loading...

Loading...