VERIFY PROPER OPERATION AFTER SERVICINGVERIFY PROPER OPERATION AFTER SERVICING

Failure to adhere to these guide-

lines can result in severe per-

sonal injury, death or substantial

property damage.

ELECTRICAL SHOCK HAZARD

TURN OFF ALL POWER TO THE BOILER WHEN

SERVICING

. Internal wiring is still powered when

the switch is o.

DO NOT JUMPER DEVICES

Never jumper (bypass) any device except for mo-

mentary testing.

REINSTALL Jacket door

e boiler jacket door must be securely fastened to

the boiler to prevent boiler from drawing air from

inside the boiler room. is is particularly important

if the boiler is located in the same room as other ap-

pliances. Failure to keep the jacket door securely fas-

tened could result in severe personal injury or death.

BEFORE SERVICING or

MAKING CONNECTIONS —

ALWAYS TURN POWER OFF TO THE BOILER

TO PREVENT ELECTRICAL SURGES, WHICH

CAN DAMAGE BOILER COMPONENTS.

LABEL WIRES BEFORE

REMOVING

Label all wires prior to disconnection

when servicing controls. Wiring errors

can cause improper and dangerous

operation.

Before calling for troubleshooting assistance, ll in

the “

FreeStyle

®

Boiler Startup Data Collection

Sheet

” (page136). Record the boiler size and Con-

sumer Protection (CP) number (located on the le side

exterior of the boiler jacket).

Part number 550-142-950/0122

89

FreeStyle

®

series

2

wall mount gas-fired water boiler – boiler manual

37 Troubleshooting

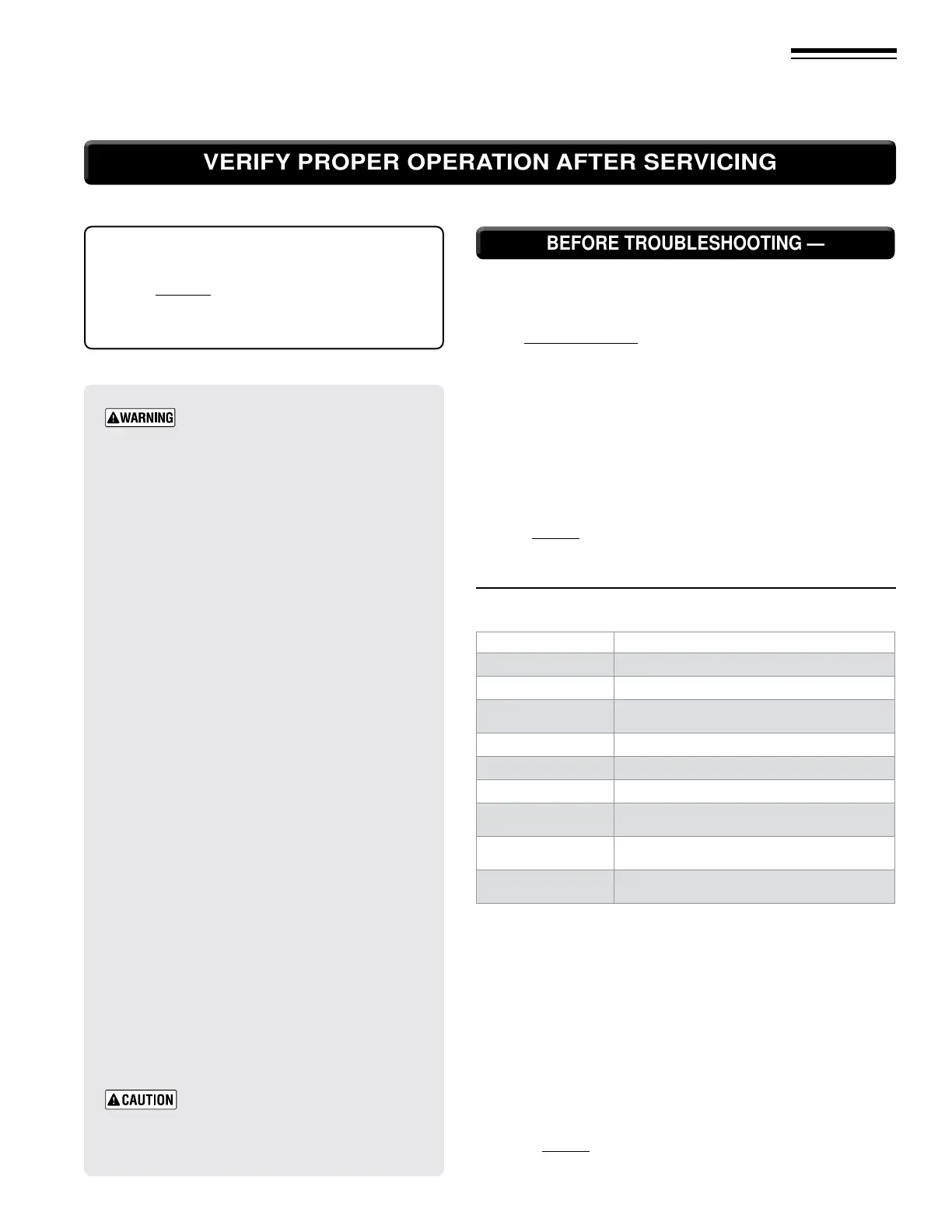

Tool Purpose

#2 Phillips screwdriver

Multiple uses

10 mm wrench

Remove heat exchanger cover plate

#20 long-handled Torx

driver

Remove burner screws

T-40 Torx driver

For gas valve adjustment

4mm Allen wrench

For gas valve Highre adjustment

Multimeter

Measurements on sensors and electrical components

Manometer

(Inclined or digital)

Measures the INLET gas pressure to the boiler

Combustion analyzer

(Digital preferred)

Combustion testing and boiler adjustments

Contact thermometer

Checking surface temperatures of heat exchanger and

pipes

Check the following:

1. Make sure thermostat is calling for heat and contacts (including

appropriate zone controls) are closed. Make sure all external limit

controls are either installed (and closed) or temporarily jumpered

for testing.

2. Make sure that connectors to control are securely plugged in at

module and originating control.

3. Gas pressures:

y Maximum: 13” w.c. with no ow (gas valve lockup pressure).

y Minimum: must be no less than the minimum values given

on page14 while operating on high re.

BEFORE TROUBLESHOOTING —BEFORE TROUBLESHOOTING —

1. Check for 120VAC (minimum 102VAC to maximum 132VAC)

to boiler.

2. Check the FreeStyle

®

control for error codes.

3. See Figure80,page62 for navigation instructions and the pages

following for the display key identication.

Hold reset button for 20 seconds:

y TS Flashing (parameter)

y Push heating – button

y IN ashing (information)

y Push heating – button

y HI ashing (history/fault)

y Push “Reset” once

y Push + to scroll error codes, refer to error code list Table 3,

page92.

To exit out, hold reset button for 20 seconds.

Figure 113 Tools and kits needed for troubleshooting.

Loading...

Loading...