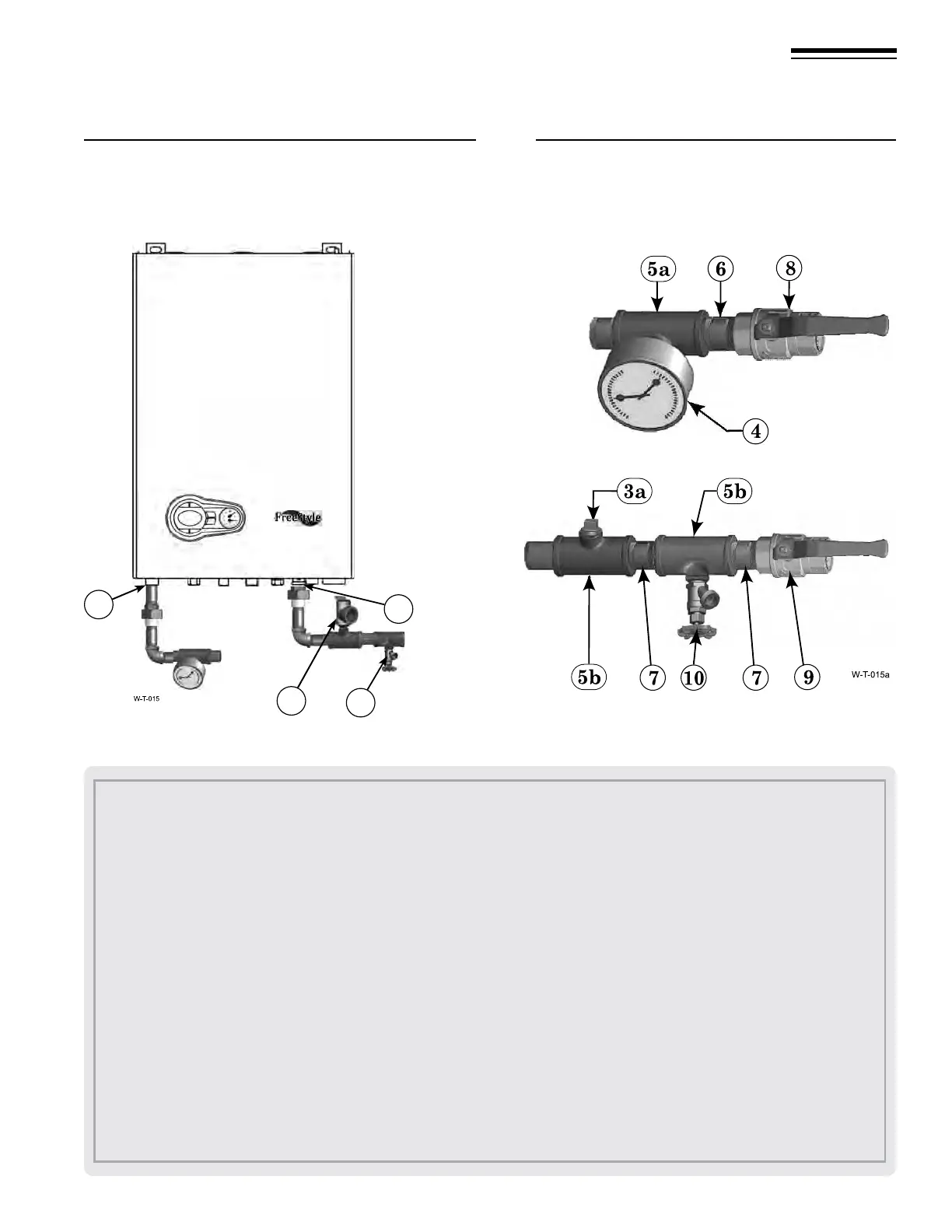

Figure 5 Install pipe ttings for relief valve and pressure/

temperature gauge —

DO NOT mount relief

valve until AFTER hydrostatic testing

(see

legend below) (Combi boiler shown)

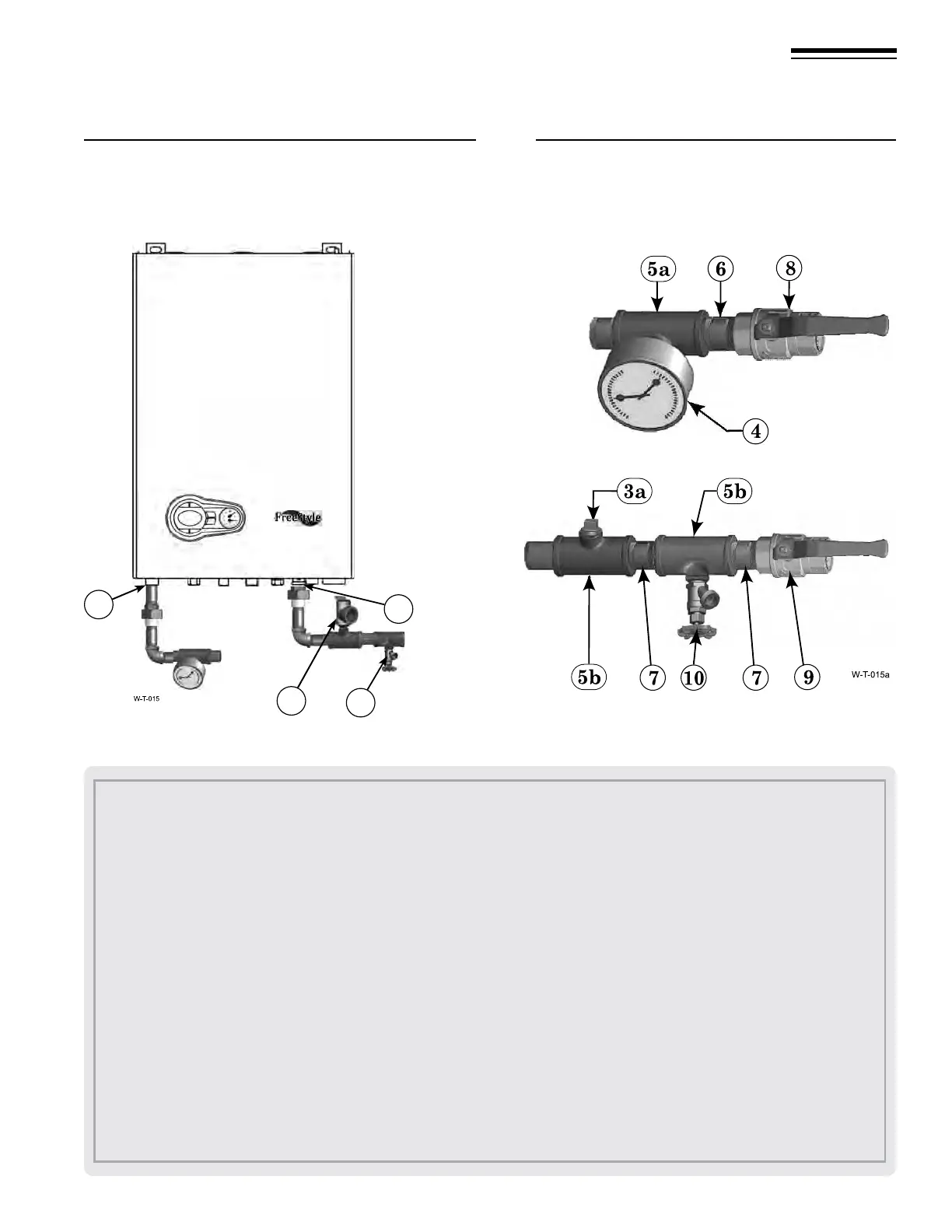

Figure 6 Install piping components required for

hydrostatic test (

see legend below)

Part number 550-142-950/0122

9

FreeStyle

®

series

2

wall mount gas-fired water boiler – boiler manual

1. Boiler supply (outlet) connection, (male, 1” NPT on FS-80/120, 1” NPT on FS-155).

2. Boiler return (inlet) connection, (male, 1” NPT on FS-80/120, 1” NPT on FS-155).

Recommend Near Boiler Piping to be 1-1/4” NPT or larger for FS-155. Bushing 1” x 1-1/4” NPT at Supply (outlet) and Return (inlet)

not shown. (eld supplied

by installer)

3. Boiler relief valve, shipped loose with boiler — DO NOT mount relief valve until AFTER hydrostatic testing.

3a.

TEMPORARIL

Y ONLY — Insert a ¾” NPT plug in the relief valve tapping of the reducing tee. This MUST BE REMOVED

after the test and the relief valve mounted here.

4.

P

ressure/temperature gauge,

(eld supplied) by installer

5a.

Re

ducing tee, NPT, 1” x 1” x ¼” on FS-80/120, NPT, 1-¼” x 1-¼” x ¼” on FS-155.

5b. Tee, NPT, 1” x 1” x ¾” on FS-80/120, NPT, 1-¼” x 1-¼” x ¾” on FS-155.

6.

N

ipple, NPT 1”x close on FS-80/120, NPT, 1-¼” x close on FS-155,

(eld supplied) by installer.

7.

N

ipple, NPT 1”x close on FS-80/120, NPT, 1-¼” x close on FS-155,

(eld supplied) by installer.

8.

I

solation valve on supply connection,

(eld supplied) by installer (1”NPT on FS-80/120, 1-¼”NPT on FS-155).

9. Isolation valve on return connection, (eld supplied) by installer (1”NPT on FS-80/120, 1-¼”NPT on FS-155).

10. ¾” NPT boiler drain valve, (eld supplied) by installer — aer hydrostatic testing, move drain valve to lowest point on the return

piping if not already there.

3 Prepare boiler continued

2

1

Boiler Return

(inlet)

Boiler Supply

(outlet)

3

10

Loading...

Loading...