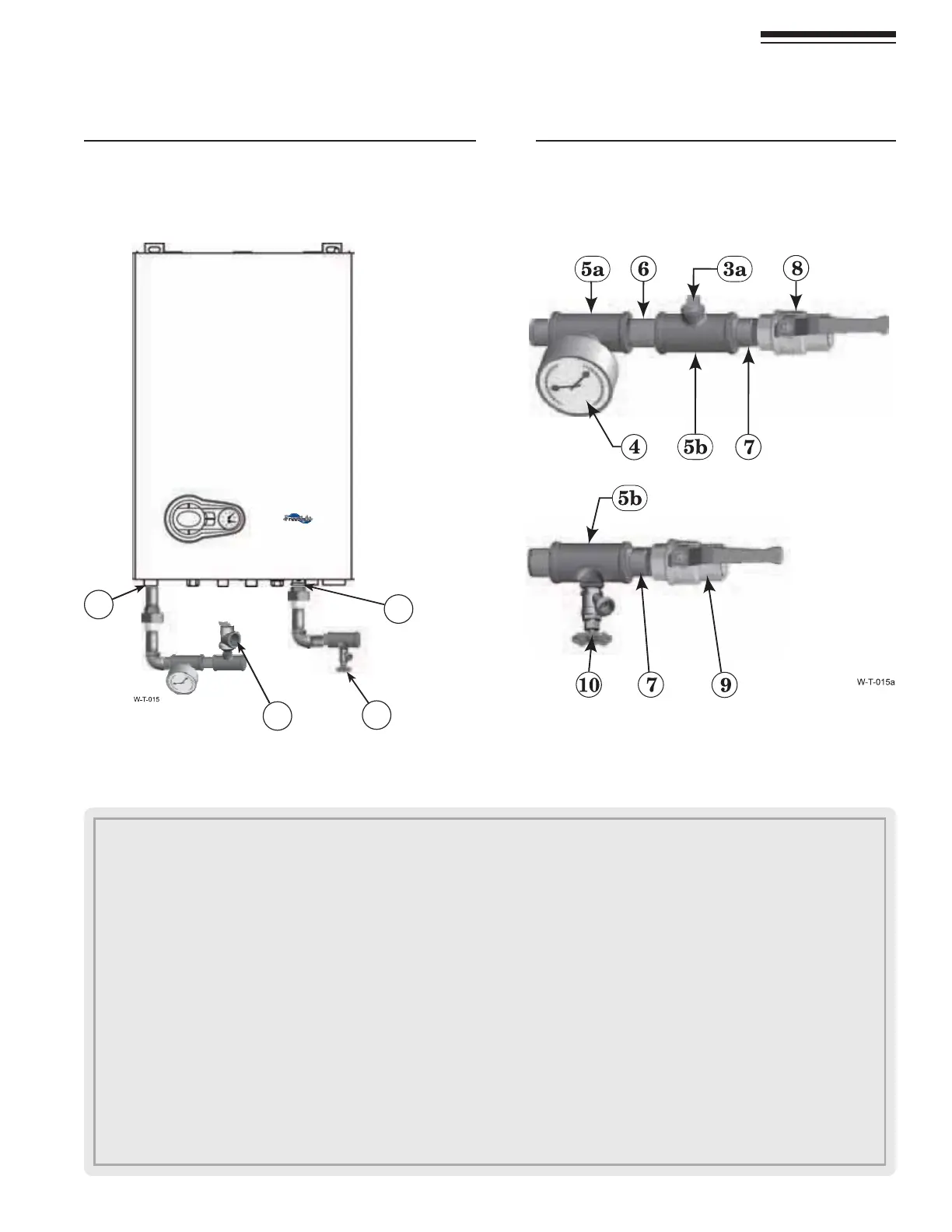

Figure 6 )NSTALLPIPElTTINGSFORRELIEFVALVEANDPRESSURE

TEMPERATUREGAUGE

$/./4MOUNTRELIEF

VALVEUNTIL!&4%2HYDROSTATICTESTING

(see

legend below)

&IGURE )NSTALLPIPINGCOMPONENTSREQUIREDFOR

HYDROSTATICTEST

see legend below)

Part number 550-142-850/0716

11

FreeStyle

®

WALL MOUNT GAS-FIRED WATER BOILER — Boiler Manual

1. Boiler supply (outlet) connection, (male, ¾” NPT on FS-80/120, 1”NPT on FS-155).

2. Boiler return (inlet) connection, (male, ¾” NPT on FS-80/120, 1”NPT on FS-155).

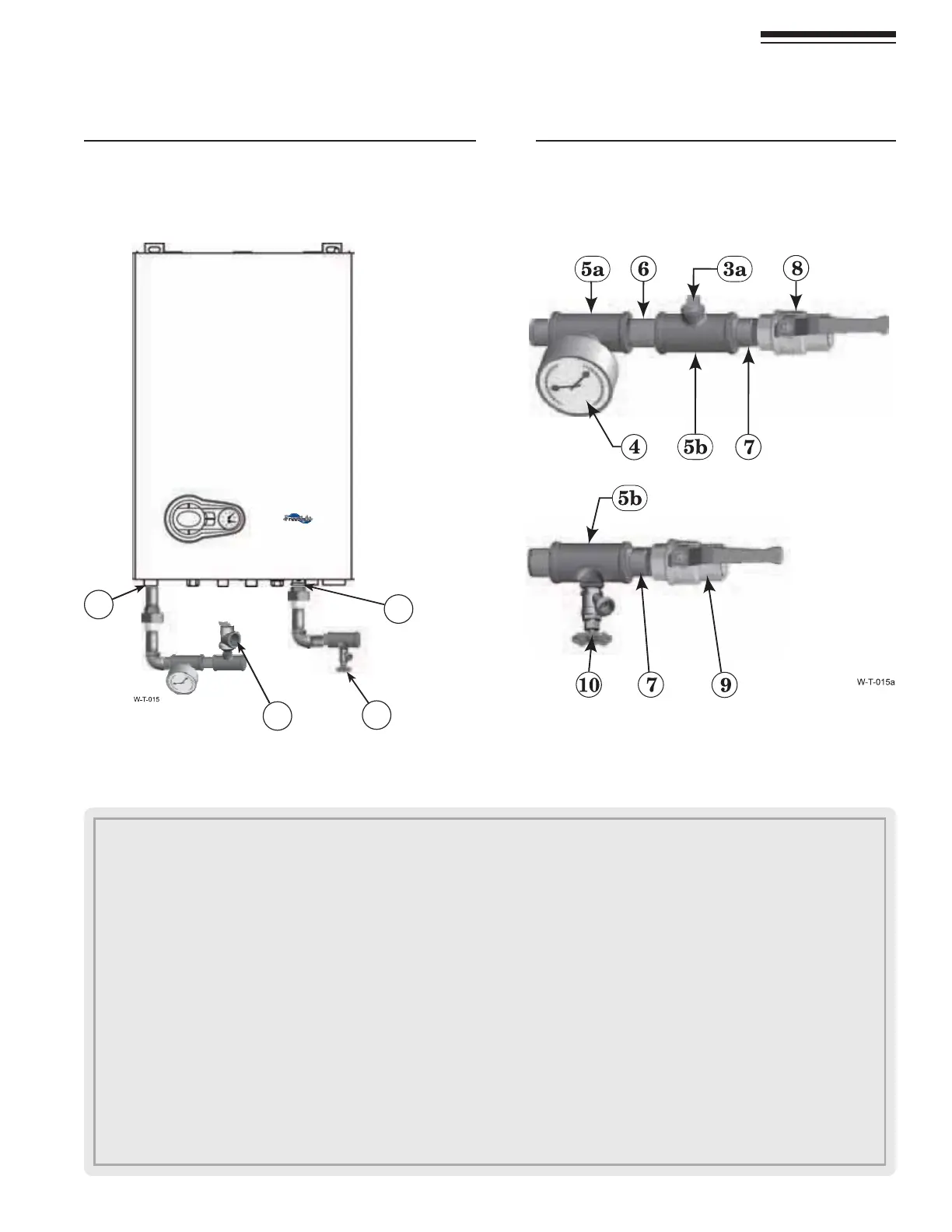

3. Boiler relief valve, shipped loose with boiler — $/./4MOUNTRELIEFVALVEUNTIL!&4%2HYDROSTATICTESTING.

3a. 4%-0/2!2),9/.,9 Insert a ¾” NPT plug in the relief valve tapping of the reducing tee. 4HIS-534"%2%-/6%$

after the test and the relief valve mounted here.

4. Pressure/temperature gauge,

(field supplied) by installer

5a. Reducing tee, NPT, ¾ ” x ¾” x ¼” on FS-80/120, NPT, 1 ” x 1” x ¼” on FS-155.

5b. Tee, NPT, ¾ ” x ¾ ” x ¾” on FS-80/120, NPT, 1 ” x 1” x ¾” on FS-155.

6. Nipple, NPT ¾” x close on FS-80/120, NPT, 1 ” x close on FS-155,

(field supplied) by installer

7. Nipple, NPT ¾” x close on FS-80/120, 1 ” x close on FS-155,

(field supplied) by installer

8. Isolation valve on supply connection,

(field supplied) by installer (¾” NPT on FS-80/120, 1”NPT on FS-155).

9. Isolation valve on return connection, (field supplied) by installer (¾” NPT on FS-80/120, 1”NPT on FS-155).

10. ¾” NPT boiler drain valve, (field supplied) by installer — after hydrostatic testing, move drain valve to lowest point on the return piping

if not already there.

3 Prepare boiler continued

0IPINGFROMSYSTEM

0IPINGTOSYSTEM

2

3

1

10

Loading...

Loading...