Part number 550-142-850/0716

15

FreeStyle

®

WALL MOUNT GAS-FIRED WATER BOILER — Boiler Manual

4 Converting boiler to propane continued

4HEJACKETDOORMUSTBEINPLACEDURING

OPERATION

DO NOT operate the boiler with

THEJACKETDOORREMOVEDEXCEPTFORINSPECTION

and testing as directed in this manual.

Inspect the gas pipe fitting connections on the gas

valve and new venturi (Item 3, Figure 15) check the

SEALOFTHECONNECTIONS&AILURETOCOMPLYWILLCAUSEA

gas leak, resulting in severe personal injury or death.

$ONOTCHECKFORGASLEAKSWITHANOPENmAMEUSE

BUBBLETEST&AILURETOUSEBUBBLETESTORCHECKFOR

gas leaks can cause severe personal injury, death or

substantial property damage.

6. Reinstall control module, reinstall screw to hold control mod-

ule securely in place.

7. Reinstall jacket door, and secure with two (2) screws.

Setup for normal operating sequence of ignition system.

8. Adjust parameter for the type of gas:

a. Put the boiler in standby mode.

b. Press the DHW buttons details 1 and 2 - Figure 74, page 60

FORSECONDSTHEDISPLAYSHOWShB“ flashing.

c. Press the DHW buttons Figure 74, page 60 details 1 and 2

TOSETPARAMETERFORUSEWITHNATURALGASOR

FORUSEWITH,0

d. Press the Heating (+) button to scroll to Parameter “Bv.

E0RESS$(7TOREDUCETHE-AXIMUM&AN3PEED,

see Figure 119, page 93:

s &ROMTOFORTHE&3BOILER

s &ROMTOFORTHE&3BOILER

s &ROMTOFORTHE&3BOILER

F0RESSTHEBUTTONTOSCROLLTO0ARAMETERhBv.

g. Repeat Step “e” above according to your boiler size.

h. Press the Heating (+) button to scroll to Parameter “Bv

I0RESS$(7TOINCREASETHE-INIMUM&AN3PEED,

see Figure 119, page 93:

s &ROMTOFORTHE&3BOILER

s .OCHANGENEEDEDFORTHE&3BOILERS

j. Press the DHW buttons details 1 and 2 -

Figure 74, page 60FORSECONDS

k. The boiler will return to standby mode.

9. Check the working pressure.

10. 4ESTIGNITIONSYSTEMSAFETYSHUTOFFSEEPAGE74.

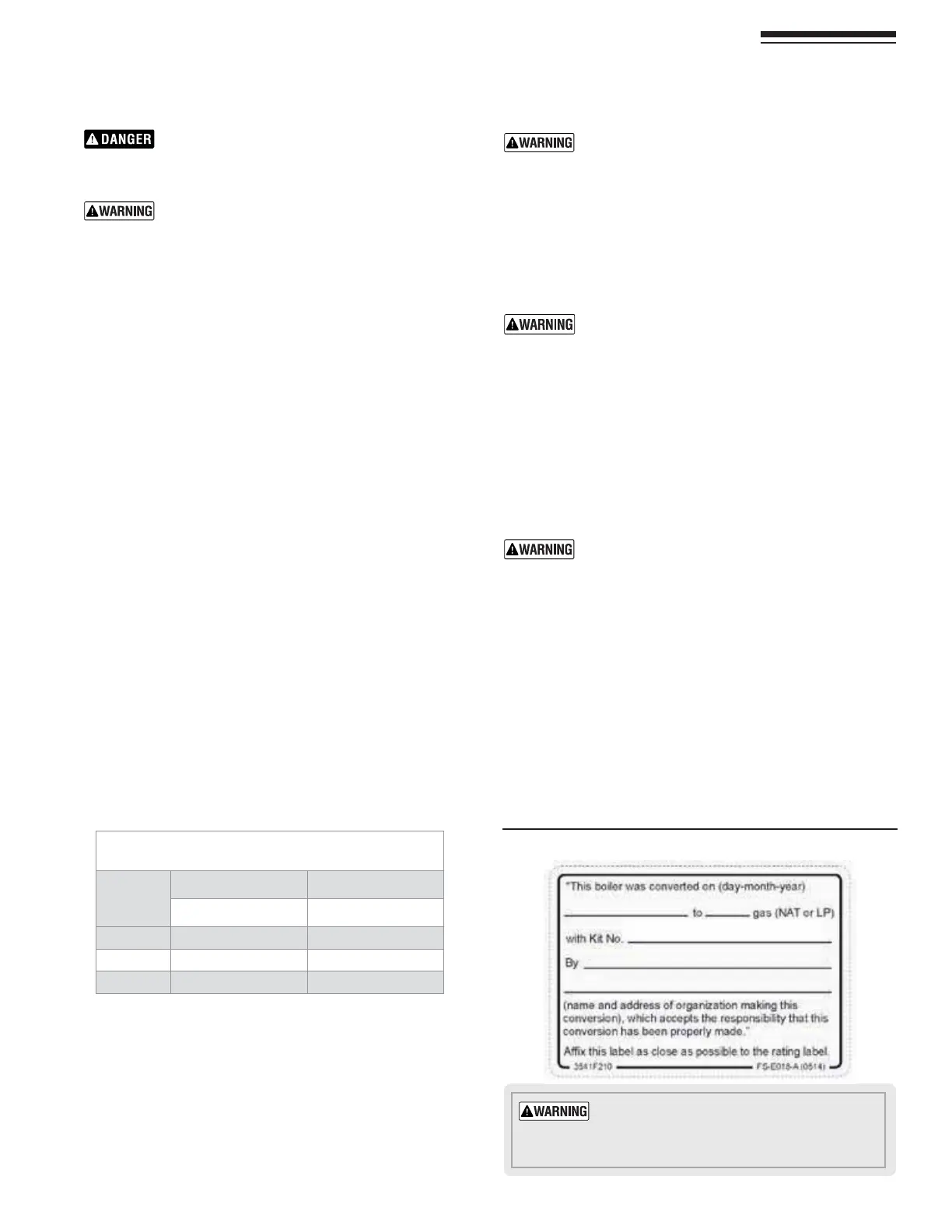

'AS2ATE.ATURAL'AS

!FTERMINUTESFROMCOLD

Combi

Boiler

model

Maximum rate Minimum rate

ft

3

/h ft

3

/h

&3

78.4 7.8

&3

117.6 11.8

&3

151.9 15.3

11. 4HE REQUIREDINPUT RATING OF THE CONVERTEDBOILER DOESNT

change.

12. )N53!)NPUTRATESAREDERATEDFOREACHFTABOVESEA

LEVELBEYONDFTINACCORDANCEWITH.ATIONAL&UEL'AS

#ODE!.3):.&0!

13. Using a combustion analyzer insert probe into the flue test

point, check that the CO

2

content in the exhaust, with the

boiler operating at max. and min. firing rate, matches that given

in the technical data Figure 98, page 73 or Figure 101, page 74,

FORTHECORRESPONDINGTYPEOFGAS

$/ ./4 !44%-044/ -%!352%6!,6%

/54,%4 02%3352% The valve could be

DAMAGEDBY MANOMETERFLUID CONTAMINATION

Failure to comply could result in severe personal

injury, death or substantial property damage.

14. Restore electrical power, turn on gas by opening manual gas

VALVECHECKFORLEAKS

Perform Boiler Manual start-up

&OLLOWALLINSTRUCTIONSIN"OILER-ANUALTOSTARTUP

THEBOILERAFTERCONVERTINGFORPROPANE"ECAUSETHE

boiler has been changed, you must verify correct

operation, including checking combustion with

test instruments both at high fire and low fire as

described in the Boiler Manual, pages 69, 70 & 71.

#HECKTHECORRECTIGNITIONSEQUENCEOFTHEBOILER

AFTERTHECONVERSIONASINPAGE82.

Failure to comply could result in severe personal

injury, death or substantial property damage.

Replace boiler jacket front door

2EPLACEBOILERJACKETFRONTDOORAFTERSERVICING4HE

BOILERFRONTDOORMUSTBESECURELYFASTENEDTOTHE

BOILERFRAME TOPREVENTBOILER FROM DRAWING AIR

FROMINSIDE THEBOILER ROOM4HISIS PARTICULARLY

IMPORTANT IF THEBOILERIS LOCATED IN THE SAME

room as other appliances. Failure to keep the door

SECURELYFASTENED COULDRESULT IN SEVEREPERSONAL

injury or death.

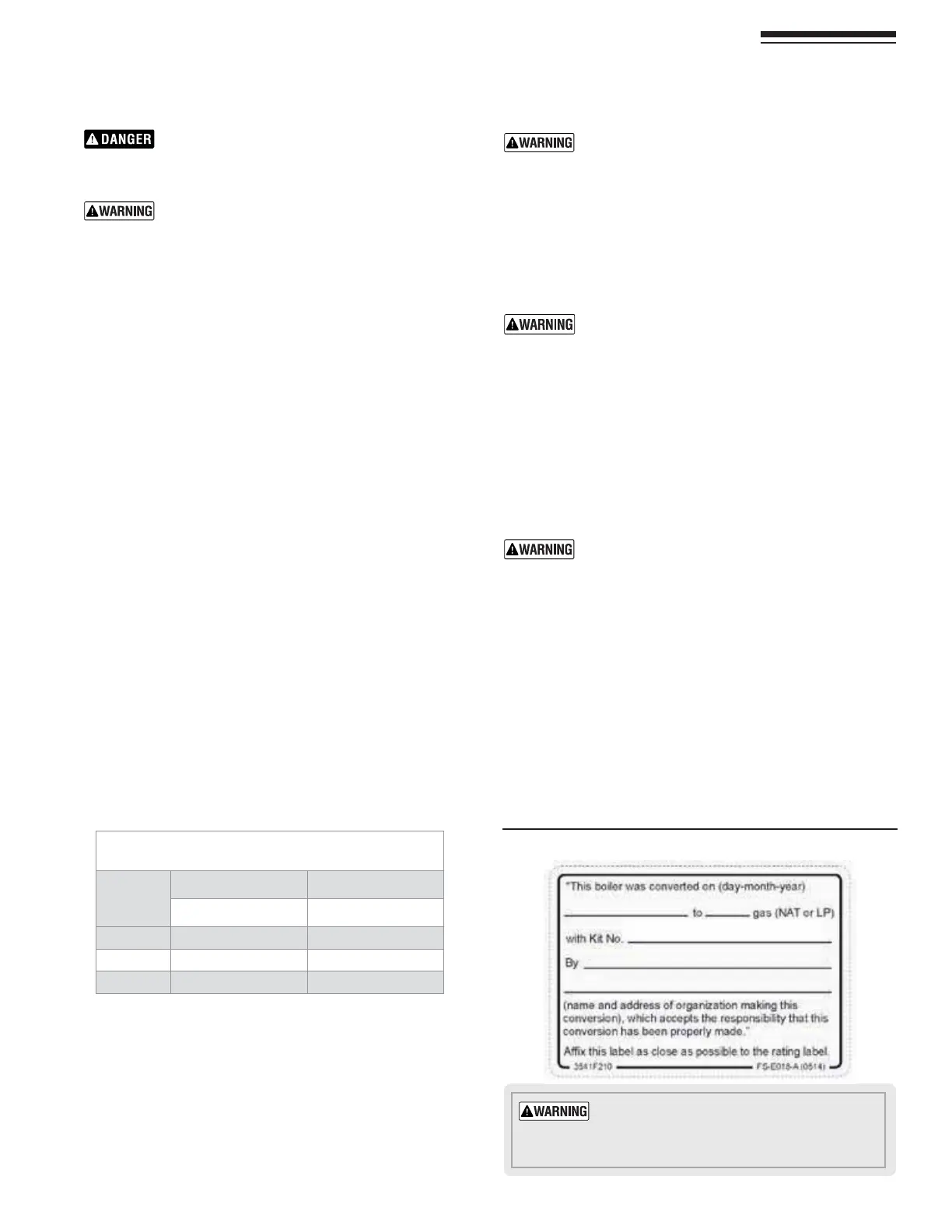

Apply installer conversion label

1. #ONVERTINGTOPROPANElRING!FTERINSTALLATIONISCOMPLETE

ATTACHTHEPROPANECONVERSIONLABELFROMKITNEXTTOTHE

boiler rating label.

#ONTRACTORINSTALLER ISRESPONSIBLEFOR COMPLETINGTHE IN-

FORMATIONREQUIREDONLABELPROVIDEDINKITANDATTACHING

installer conversion label next to the boiler rating label.

&IGURE )NSTALLERCONVERSIONLABEL

Loading...

Loading...