070.750-IOM2 (JUN 22)

Page 12

HPS 273 and 407 Rotary Screw Compressor

Installation

Foundation

Each HPS Rotary Screw Compressor is shipped mounted

on a wooden skid. Remove before installing the unit.

Caution

Allow correct spacing for servicing. See the relevant

dimensional outline drawing.

The rst requirement of the compressor foundation is that

it must be able to support the weight. The weights of the

HPS 2709 and HPS 2712 assemblies respectively are 2,132

kg (4,700 lb) and 2,241 kg (4,940 lb). The weights of the

HPS 4009 and HPS 4012 compressor models respectively

are 5,185 kg (11,432 lb) and 5,519 kg (12,167 lb).

Screw compressors are capable of converting large quan-

tities of shaft power into gas compression in a relatively

small space. The compression process creates relatively

high frequency vibrations that require sufcient mass

in the base to effectively dampen them. Refer to FRICK

070.210-IB, Screw Compressor Foundations.

The best insurance for a trouble-free installation is to

rmly anchor the compressor to a suitable foundation

using correct bolting and by preventing piping stress from

being imposed on the compressor. After rigging the com-

pressor into place, you must shim its feet to level it. There

must be absolutely no stresses transferred to the com-

pressor body due to bolting of the feet and anges.

In any screw compressor installation, support suction and

discharge lines in pipe hangers, preferably within 2 ft (0.61

m) of vertical pipe run, so that the lines won’t move if dis-

connected from the compressor. See Table 8 for allowable

ange loads.

Motor mounting, for foot-mounted

motor only

1. Thoroughly clean the motor feet and mounting pads of

grease, burrs, and other foreign matter to ensure rm

seating of the motor.

2. Attach the motor to the base using bolts and motor

raising blocks, if required.

3. Weld the four kick bolts into place so that they are

positioned to allow movement of the motor feet. The

kick bolts are not included with compressor.

4. After setting the motor, check to see that the shafts

are correctly spaced for the coupling being used. Check

the appropriate dimensional outline drawing for the

minimum clearance required between the shaft ends to

change the shaft seal.

Compressor/motor coupling requirements

HPS compressors are arranged for direct motor drive and

require a exible drive coupling to connect the compressor

to the motor. Coupling must be suitable for variable speed.

The HPS 273 and 407 models use a keyless drive shaft.

For a foot-mounted motor, it is essential to correctly align

the coupling to ensure correct bearing and seal perfor-

mance:

1. Select and install the coupling so that it does not trans-

mit any axial load to the compressor shaft.

2. Set up the minimum distance between the compressor

shaft and motor shaft to enable seal removal. See the

relevant outline drawings.

3.

Coupling must be able to take up any misalignment

between the motor and compressor. It is critical to the

life of the shaft seal that misalignment is kept to the

minimum possible value. Follow the coupling manu-

facturer’s guidelines for checking and correcting any

misalignment.

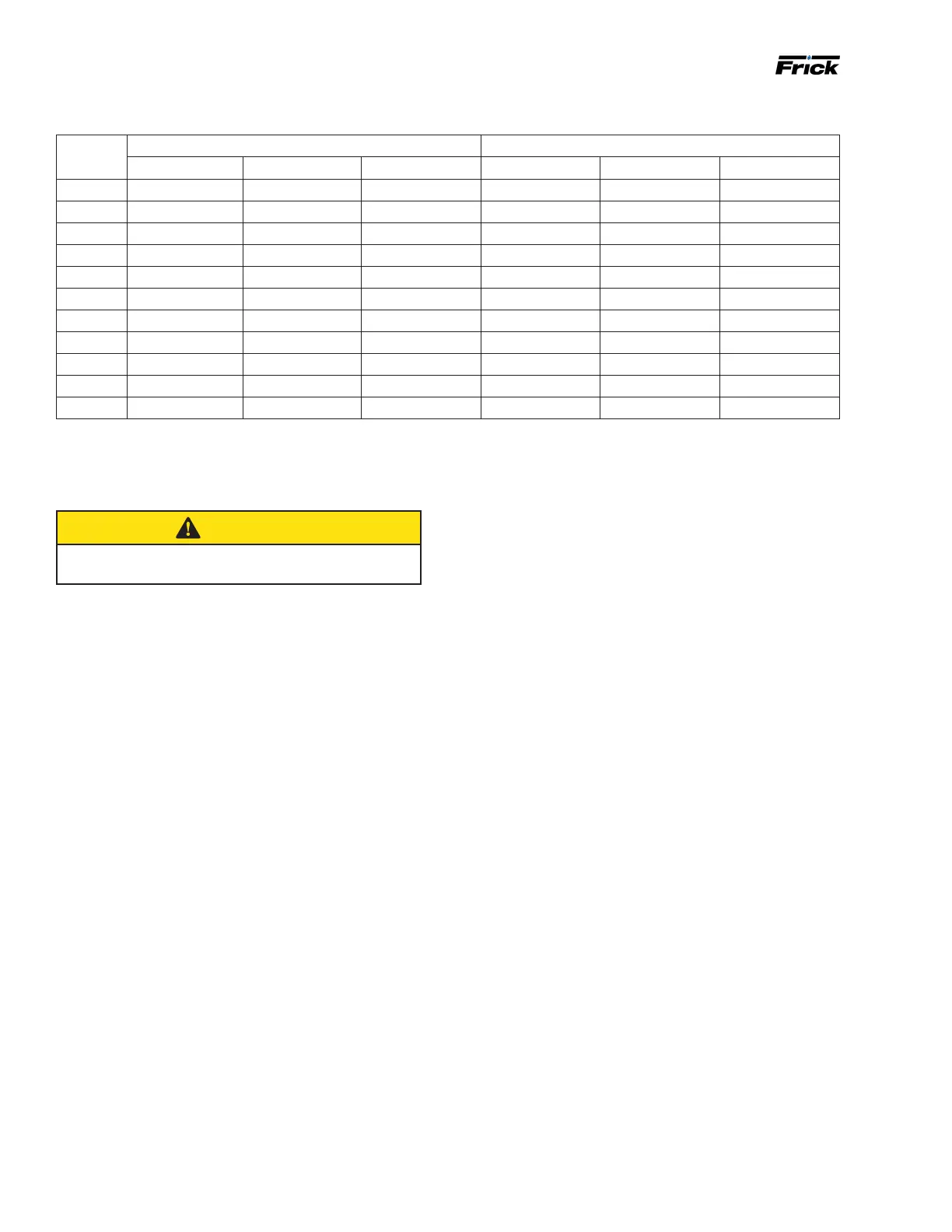

Table 8: Allowable ange loads

Nozzle

size NPS

Moments, ft-lbf (N

.

m) Load, lbf (N)

Axial - M

R

Vert. - M

C

Lat. - M

L

Axial - P Vert. - V

C

Lat. - V

L

1 25 (34) 25 (34) 25 (34) 50 (222) 50 (222) 50 (222)

1.25 25 (34)

25 (34) 25 (34) 50 (222) 50 (222) 50 (222)

1.5 50 (68) 40 (54) 40 (54) 100 (445) 75 (334) 75 (334)

2 100 (136) 70 (95) 70 (95) 150 (667) 125 (556) 125 (556)

3 250 (339) 175 (237) 175 (237) 225 (1,001) 250 (1,112) 250 (1,112)

4 400 (542) 200 (271) 200 (271) 300 (1,334) 400 (1,779) 400 (1,779)

5 425 (576) 400 (542) 400 (542) 400 (1,779) 450 (2,002) 450 (2,002)

6 1,000 (1,356) 750 (1,017) 750 (1,017) 650 (2,891) 650 (2,891) 650 (2,891)

8 1,500 (2,034) 1,000 (1,356) 1,000 (1,356) 1,500 (6,672) 900 (4,003) 900 (4,003)

10 1,500 (2,034) 1,200 (1,627) 1,200 (1,627) 1,500 (6,672) 1,200 (5,338) 1,200 (5,338)

14 2,000 (2,712) 1,800 (2,440) 1,800 (2,440) 1,700 (7,562) 2,000 (8,896) 2,000 (8,896)

Loading...

Loading...