070.750-IOM2 (JUN 22)

Page 22

HPS 273 and 407 Rotary Screw Compressor

Maintenance

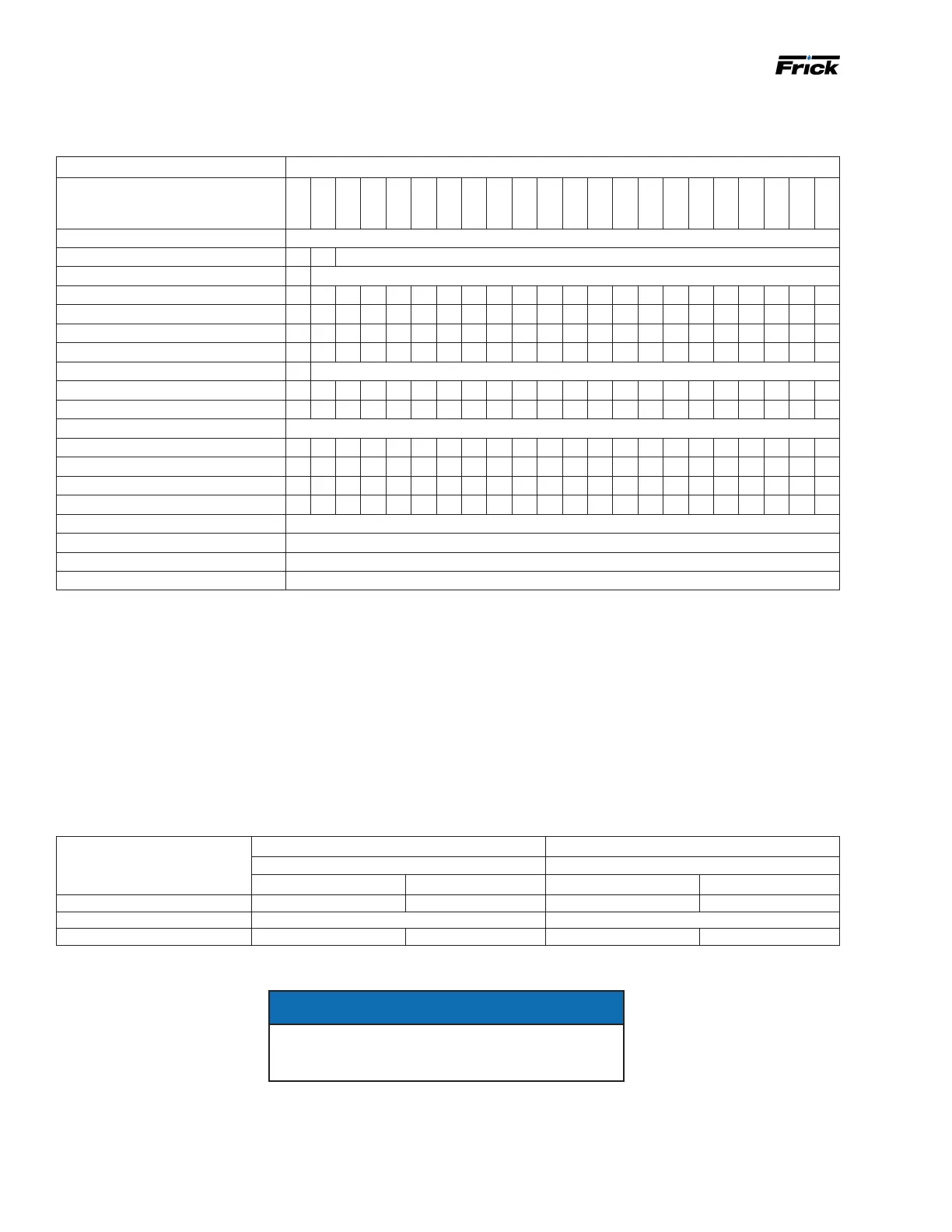

Maintenance schedule

Follow this schedule to ensure trouble-free operation of the compressor unit.

Notice

Refer to the service parts list manual 070.750-SPL2,

HPS Rotary Screw Compressor SPL2 (273), for a

detailed parts list.

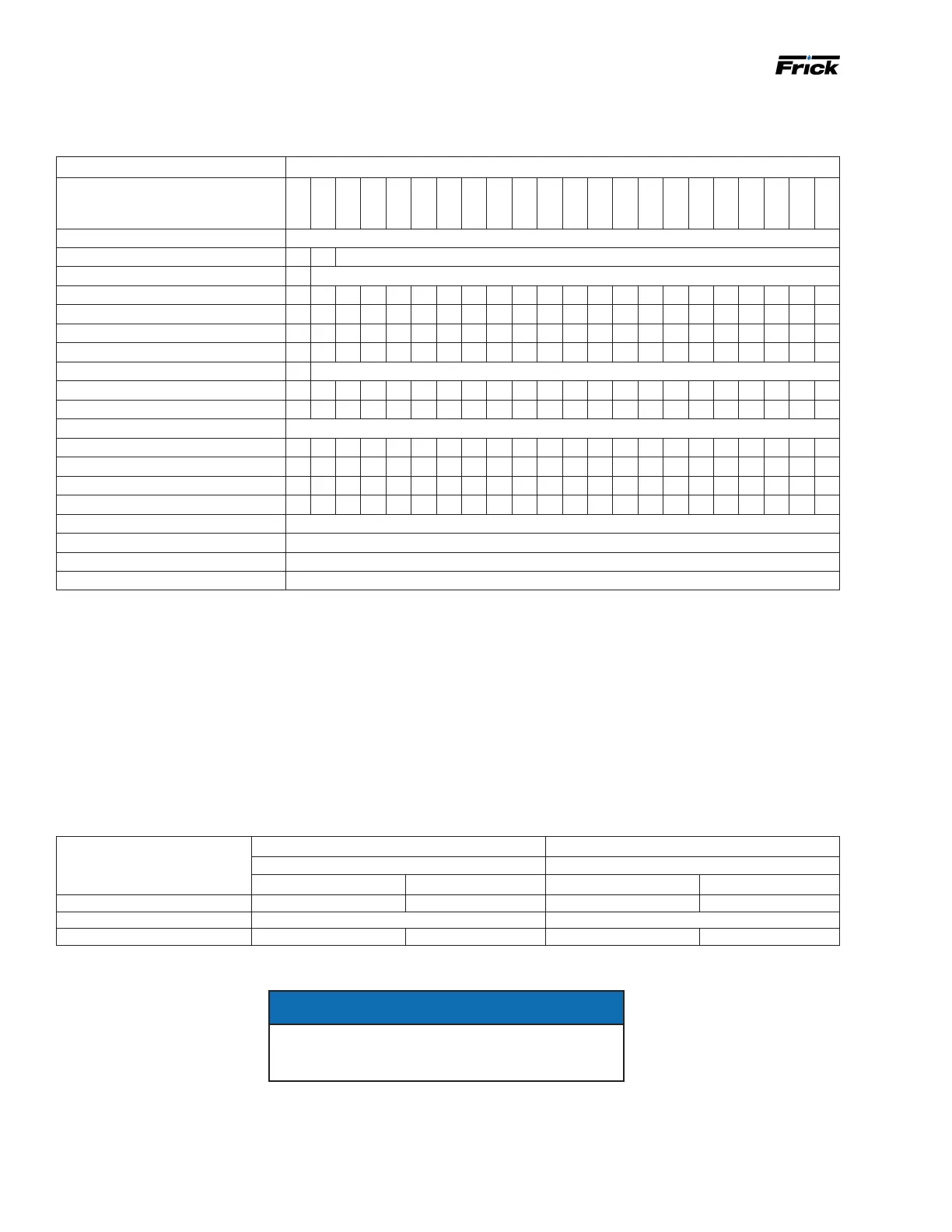

Compressor

model

Discharge ange to separator ange Suction ange

6 in. Class 600 8 in. Class 600

Bolt size (in.) Torque* (ft-lb) Bolt size (in.) Torque (ft-lb)

HPS 2709/2712 1 406 1 1/8 647

8 in. Class 600 12 in. Class 600

HPS 4009/4012 1 1/8 647 1 1/4 845

Note: Based on using stainless steel spiral wound gaskets and Grade 5 or stronger hex head bolts, lighlty oiled.

Table 9: Bolt sizes and torque

Frequency or hours of operation (maximum)

Maintenance

200

1000

5000

8000

10,000

15,000

20,000

25,000

30,000

35,000

40,000

45,000

50,000

55,000

60,000

65,000

70,000

75,000

80,000

85,000

90,000

95,000

Change oil

As directed by oil analysis

Oil analysis

n

Every 6 months

Replace oil lters

n

As directed by oil analysis

Clean oil strainers

n n n n n n n n n n n

Clean liquid strainers

n

n n n n n n n n n n

Replace coalescers

n n n

Check and clean suction strainer

n n n n n n n n n n n

Check coupling

n

Annually regardless of operating hours

Check alignment

n n n n n n n n n n n

Suction and discharge ange bolts

n n n n n n n n n n n n n n n n n n n n n n

VFD units check skip frequency Check annually

Check electrical connections

n n

n n n n n n n n n n n n n n n n n n

Check linear transmitter

n

n n n n n n n n n n n n n n n n n n n

n

Check sensor calibration

n

n n n n n n n n n n n n n n n n n n n

n

Check BPR function

n n n n n n n n n n n n n n n n n n n n n n

Test high pressure cut-out Test annually

Vibration analysis Every 6 months or more frequently if levels increase

Motor grease Follow the motor manufacturer’s recommendation

Replace shaft seal When a leak rate exceeds 7 to 8 drops a minute (600 ml in 24 )

Notes:

• For couplings, check bolts, shim packs, center inserts, keys, and all bolt torques.

• For suction and discharge ange bolts, verify the tightness of the bolts. See Table 9 for torque requirements.

• For variable frequency drive (VFD) units, check for excess vibration and skip frequencies any time unit operating conditions change.

• For electrical connections, check and torque all terminals in the processor and starter panel in accordance with the specication posted in

the enclosure.

• For linear transmitters, see Calibrating the linear transmitter.

• For sensor calibration, check pressures and temperatures using a NIST certied device.

• For vibration analysis, baseline vibration analysis is required during initial commissioning. Vibration measurement must be carried out con-

tinuously to obtain optimum preventive control on bearings. If not continuously controlled, then every 6 months, more frequently if levels

increase. See additional notes in Maintenance program.

• When replacing oil lters, you may need to change the lter more frequently based on differential pressure or as directed by oil analysis.

• For checking alignment, refer to 070.210-IB, Screw Compressor Foundations for foot-mounting alignment.

Loading...

Loading...