070.750-IOM2 (JUN 22)

Page 9

HPS 273 and 407 Rotary Screw Compressor

Installation - Operation - Maintenance

• In CO

2

applications using miscible oil types POE and

PAG, it is critical to keep water content to the lowest

possible. Down to 10 ppm is the goal. The installation

must have large lter dryers with replaceable elements

that you can effectively service and vacuum dry before

putting back into service.

• If the temperature difference becomes greater than or

equal to 250°F (138.9°C) between suction and dis-

charge, unload the slide valve to less than 50% but

above 40%.

• The minimum discharge temperature must be at least

54°F (30°C) above the actual dewpoint of the discharge

gases. This applies to part load conditions and full load

operation.

Vibration and sound data

The rotors balance grade is G 2.5 according to ISO 1940.

The male rotor drive end of the HPS 273

and 407

com-

pressors is keyless.

Effective vibration velocity must not exceed 8 mm/s RMS

(0.32 in./s) anywhere on the compressor. Alarm level is 12

mm/s RMS (0.47 in./s).

Table 6: Number of rotor lobes

Male rotor lobes Female rotor lobes

6 8

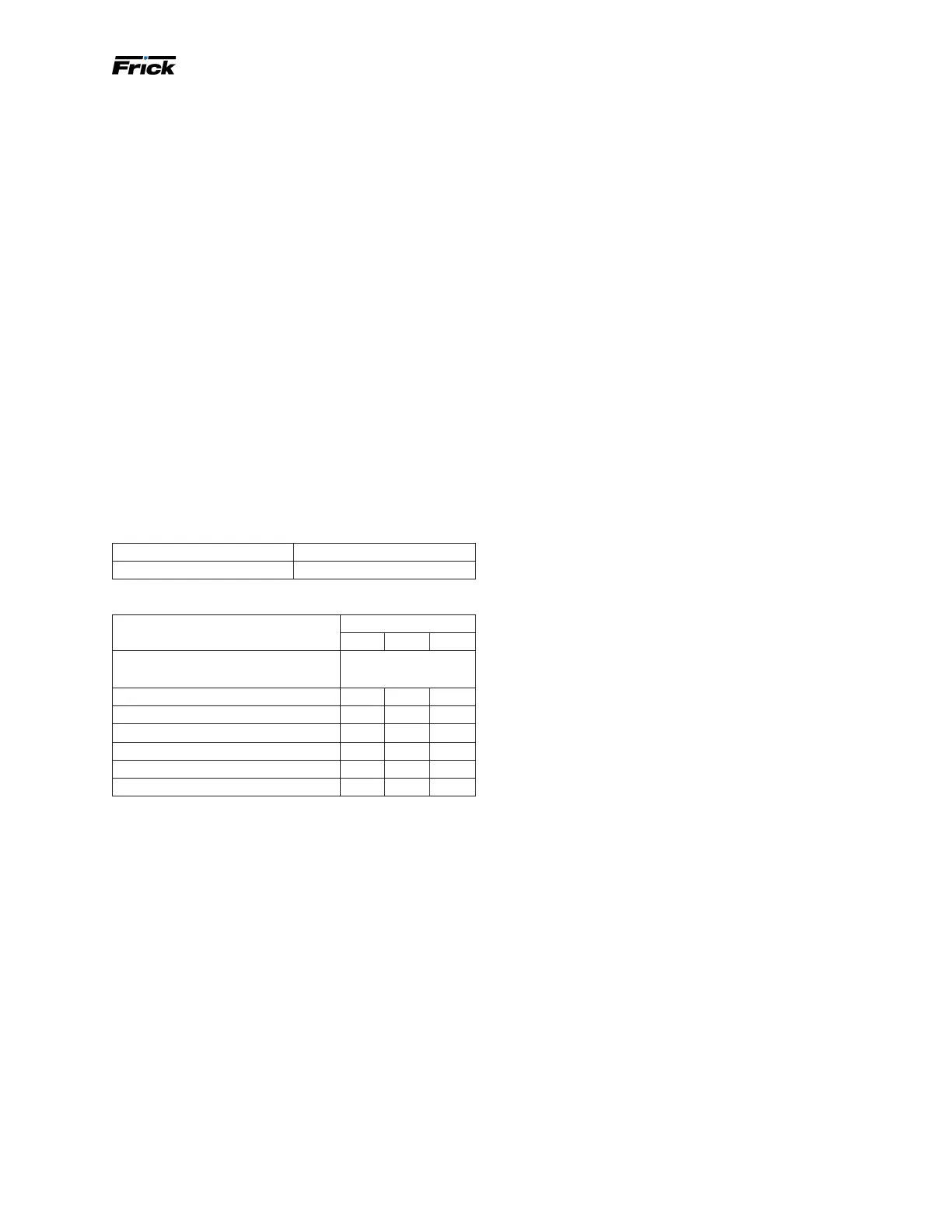

Table 7: Critical frequencies

Driver speed, rpm

3,000 3,600 4,200

Exiting member and event Main exciting fre-

quencies (Hz)

Male rotor, rotational, rst order 50 60 72

Male rotor, rotational, second order 100 120 144

Female rotor, rotational, rst 37.5 45 54

Female rotor, rotational, second 75 90 108

Discharge gas pulsation, rst 300 360 432

Discharge gas pulsation, second 600 720 864

Vibration level on the package can be higher, especially

on piping elements, and when the natural frequency of an

element falls together with one of the exciting frequen-

cies. If the vibration level gets too high, a skip frequency

function in the control system activates. After activating,

the motor runs through the critical speed very fast, not

causing any continuously high vibration.

Loading...

Loading...