070.750-IOM2 (JUN 22)

Page 13

HPS 273 and 407 Rotary Screw Compressor

Installation

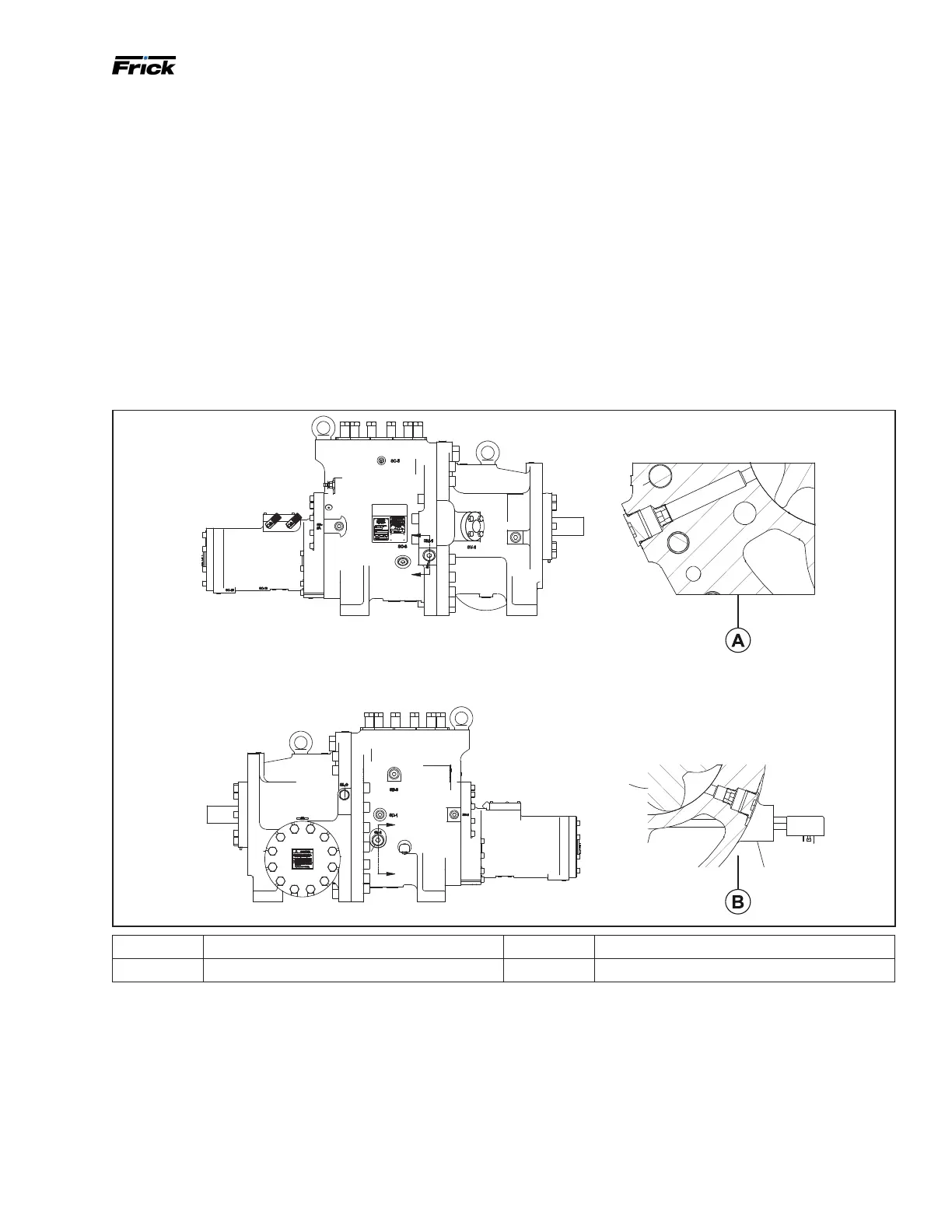

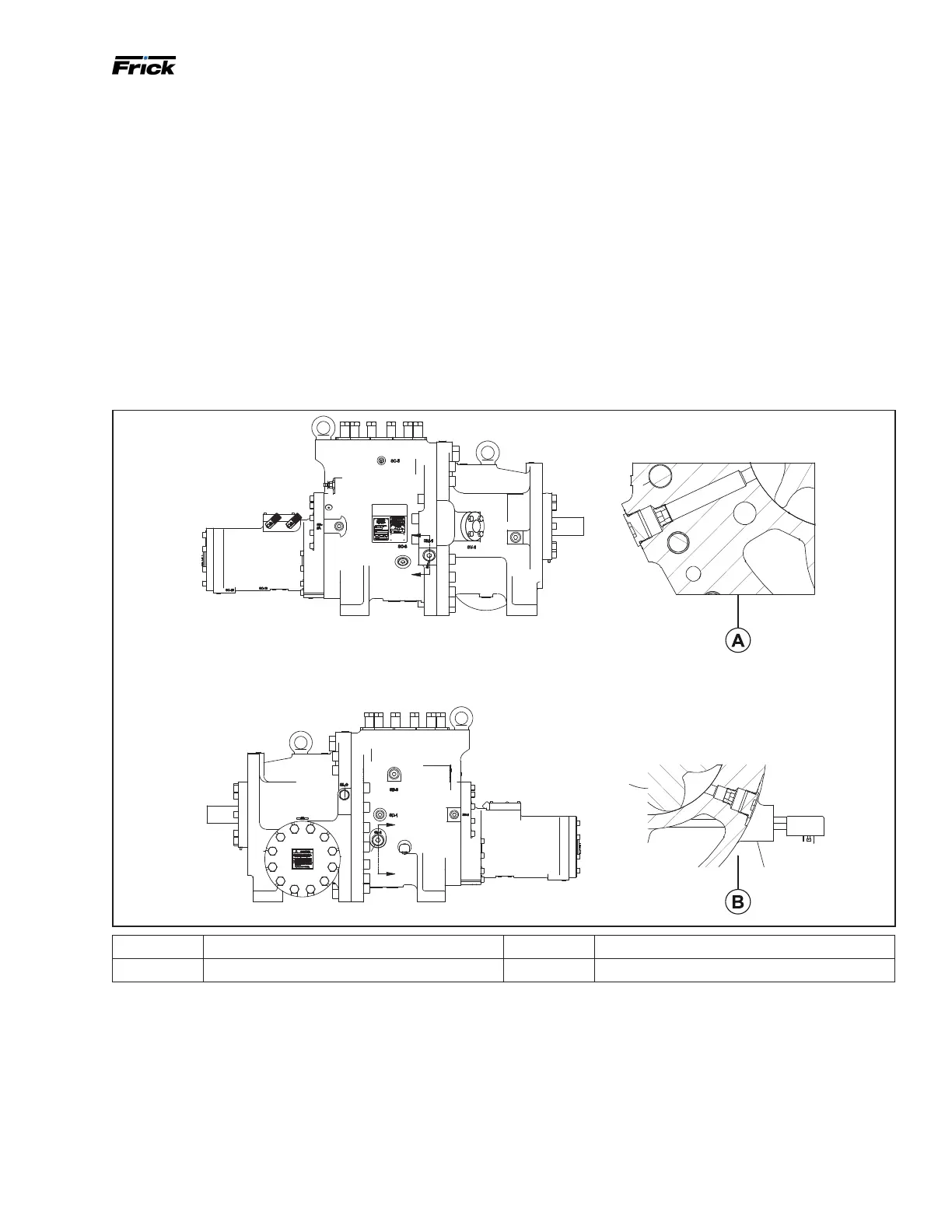

Figure 8: SM-1 and SM-2 port cutaways, HPS 273

Callout Description Callout Description

A SM-1: port SM-1 orice plug B SM-2: port SM-2 orice plug

Coupling alignment requirements,

for foot-mounted motor only

1. Perform a coupling alignment before start-up.

2. After installing the compressor on the job site, check

alignment again and if necessary, correct before start-

up.

3. After a few hours operation, you must check the align-

ment while the package is still hot. Correct hot align-

ment is critical to ensure the life of the shaft seal and

compressor bearings.

Note: Maximum radial runout is 0.004 in. total indicator

reading.

Maximum axial runout is 0.004 in. total indicator

reading.

4. Use a dial indicator or another appropriate measuring

device to determine the Total Indicator Runout.

5. Check the indicator bracket sag because all brackets

have some exibility.

a. The best way to measure this is to attach the dial

indicator and bracket on a pipe at the coupling span

distance.

b. Zero the indicator in the 12:00 position, and rotate

the pipe so the indicator is in the 6:00 position. The

reading on the indicator in the 6:00 position is the

bracket sag. This value must be included in the dial

indicator readings when afxed to the coupling for

an accurate alignment.

Customer connections

In addition to the suction and discharge connections, the

following ports require piping to operate the compressor:

SB-2: Balance piston

SB-3: Shaft seal, outlet end bearings

SM-1 or SM-2: Main oil injection. SM-1 is only used

for 2.2-5.0 Vi

SB-2a: Inlet bearings

Note: Connecting the main oil injection to the correct port

for your compressor Vi range is critical for correct

lubrication. Only use the SM-1 port for compres-

sors with a 2.2 Vi to 5.0 Vi range. If you are unsure

what Vi range the compressor has, pipe the main oil

injection line to the SM-2 port. The HPS 2709 and

HPS 2712 both have factory-installed orice plugs,

0.469 in. diameter. The factory-installed orice

plugs on the HPS 4009 and HPS 4012 are 0.875 in.

diameter.

Loading...

Loading...