070.750-IOM2 (JUN 22)

Page 5

HPS 273 and 407 Rotary Screw Compressor

Installation - Operation - Maintenance

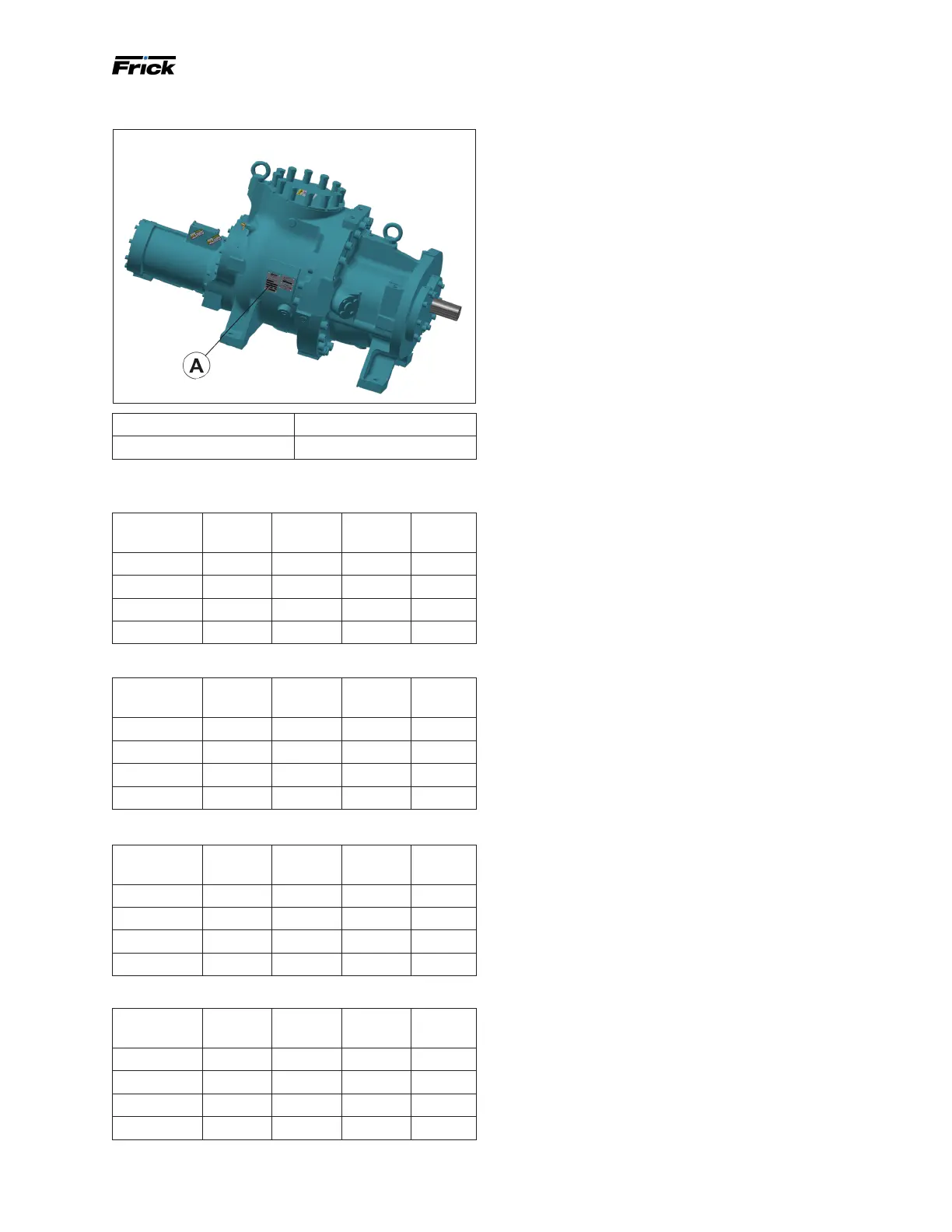

Figure 3: Nameplate and Vi locations

Callout Component

A Nameplate

See note after Table 5.

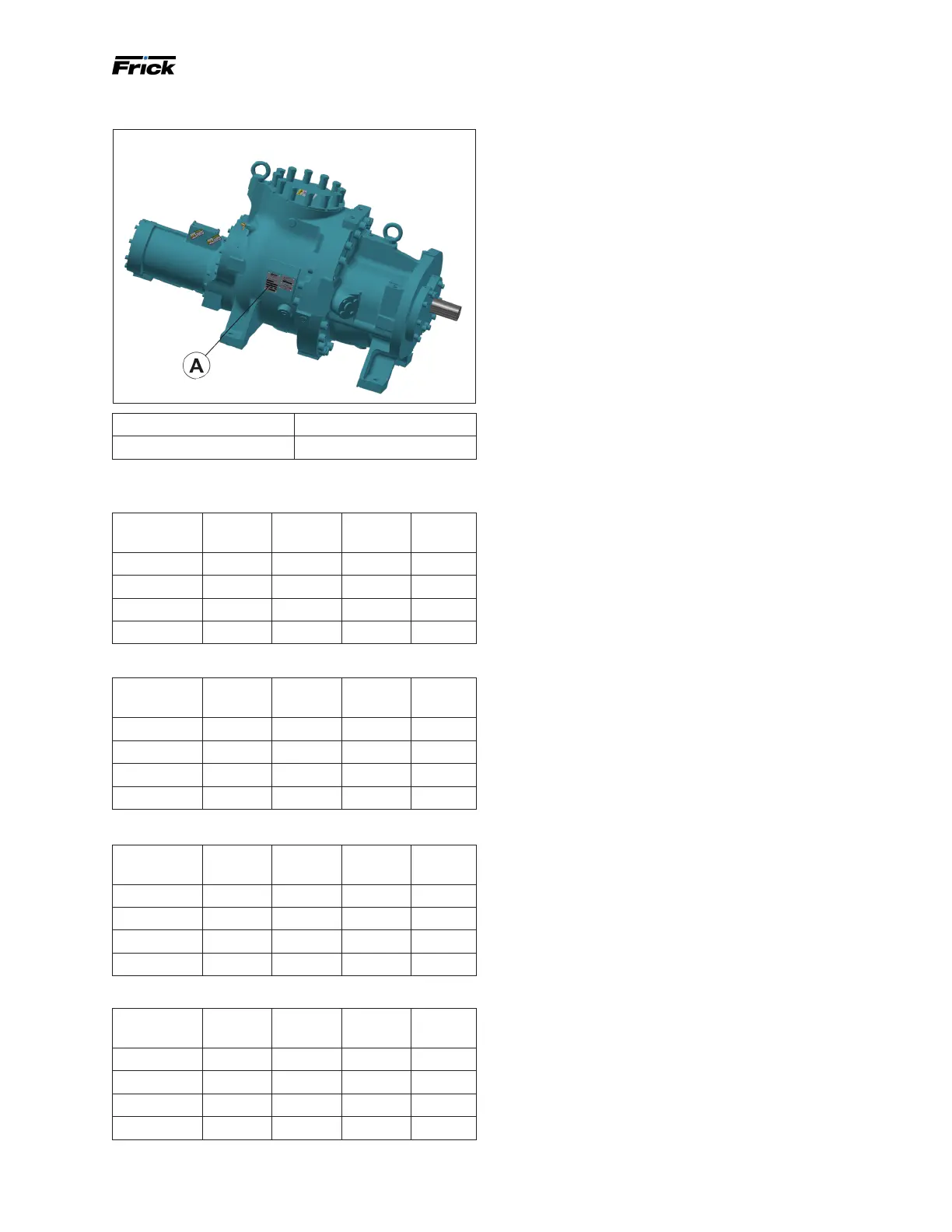

Table 2: Geometrical swept volume, 2709 model

m

3

/h cfm 1.5%

Lpm

1.5%

gpm

1,450 rpm 676 398 169 45

1,750 rpm 816 480 204 54

2,950 rpm 1,375 809 344 91

3,550 rpm 1,655 974 414 109

Table 3: Geometrical swept volume, 2712 model

m

3

/h cfm 1.5%

Lpm

1.5%

gpm

1,450 rpm 901 530 225 59

1,750 rpm 1,088 640 272 72

2,950 rpm 1,833 1,079 458 121

3,550 rpm 2,206 1,298 552 146

Table 4: Geometrical swept volume, 4009 model

m

3

/h cfm 1.5%

Lpm

1.5%

gpm

1,450 rpm 2,219 1,303 555 146

1,750 rpm 2,678 1,576 670 177

2,950 rpm 4,514 2,657 1,129 298

3,550 rpm 5,432 3,197 1,358 359

Table 5: Geometrical swept volume, 4012 model

m

3

/h cfm 1.5%

Lpm

1.5%

gpm

1,450 rpm 2,958 1,741 740 195

1,750 rpm 3,570 2,101 893 236

2,950 rpm 6,018 3,542 1,505 397

3,550 rpm 7,242 4,262 1,811 478

Note: 1.5% oil ow as a percentage of compressor

model’s swept volume

Long-term storage

Long-term storage, is defined between six months and

ve years. Provisions are required, regardless of storage

environment, if start-up and useful operation does not oc-

cur within six months of equipment shipment. Special pro-

visions may be required for storage of less than 6 months

if the storage area is subject to environments with high

humidity, large changes in temperature, dusty atmosphere,

or other unusual environmental conditions.

The standard Johnson Controls-Frick Warranty for an HPS

273 and 407 screw compressors covers 12 months from

start-up or 18 months from shipment, whichever comes

rst. Make arrangements with the local Johnson Controls-

Frick service organization, arranged through factory

service, regarding surveillance and maintenance during

the storage period. It is the customer’s responsibility to

submit a monthly report showing the condition of the unit

and noting any discrepancies to the guidelines listed in this

manual.

Note: Failure to comply with this long-term storage sug-

gestion may void the warranty.

Long-term storage of equipment may lead to the deterio-

ration of components over the period of time. Synthetic

components in the compressor may deteriorate over time

even if they are kept ooded with oil. A warm and dry

environment is essential to minimize environmental and

corrosion damage.

Follow the steps in Preparing the compressor for storage

and Maintaining the compressor in storage to maintain the

screw compressor warranty.

Preparing the compressor for storage

1. Evacuate the compressor to remove moisture.

2. Connect the evacuation lines to the three Schrader

access valves provided with the compressor. One valve

is connected to the compressor suction and the other

two valves are located at the block on the cylinder.

3. Break the vacuum with dry nitrogen and bring pressure

to 0 bar (0 psig).

4. Pump oil into the SM1. Use break-in oil part number

111Q0831809 for storage purposes.

Note: The amount of oil necessary to ll a given compres-

sor model depends on the L/D size involved and

the actual internal clearances of the compressor.

The approximate volume of oil needed to ll the

compressor is between 20 gal to 25 gal for HPS 273

compressors, and 100 gal to 120 gal for HPS 407

compressors.

Note: The gal amount of oil are average values, which

vary based on the specic HPS model.

5. After the compressor is oil charged, pressurize the

compressor to 1.0 bar (14.5 psig) with nitrogen.

See

Loading...

Loading...