070.750-IOM2 (JUN 22)

Page 8

HPS 273 and 407 Rotary Screw Compressor

Installation - Operation - Maintenance

Construction details

Housing

All HPS 273 and 407 screw compressors castings are

60-40-18 ductile iron to ensure structural integrity and me-

chanical and thermal stability under all operating conditions.

Rotors

The rotors are made from quality, wear-resistant rolled

steel to the exacting tolerances of the latest industry stan-

dard asymmetric prole. The six-lobed male rotor directly

connects to the driver. The eight-lobed female rotor is

driven by the male on a thin oil lm.

Bearings

HPS compressors are designed for optimal bearing life.

The HPS 273 and 407 compressor models are designed

with a conventional single-radial bearing design (HPSS). A

double-radial bearing arrangement (HPSD) is available as

an option to handle higher discharge pressure applications.

When evaluating operating conditions of the compres-

sor in CoolWare for performance, give consideration to

changes in those conditions based on operating transients

and seasonal changes. CoolWare automatically congures

the bearing arrangement for optimal life based on these

conditions.

Balance piston

The high pressure compressors are equipped with balance

piston assemblies to reduce load on the axial bearings. Oil

pressure is regulated by a xed or modulating pressure

regulating valve and provides the force necessary to offset

the bearing loads. The pressure setting on the balance

piston pressure regulating valve is important and specied

by Coolware for the specic operating conditions of the

compressor.

Shaft seal

The compressor shaft seal is a single-face balanced type

with a spring-loaded, silicon carbide stationary hardened

surface riding against a rotating seat. Carbon and graph-

ite are added to both surfaces to provide self-lubrication.

During operation, it is vented to low pressure to provide

extended life.

Motor mount

The HPS 273 and 407 series compressors is a foot

mounted, open drive model that can pair with an electric,

engine, or turbine drive.

Design limits

Use CoolWare to determine the limits for a specic

application.

• Maximum suction pressures for the HPS compressors

are limited based on compressor Vi, to avoid over-

compression:

– For A model 2.2 Vi to 5.0 Vi the limit is 27.5 bar

(450 psia)

– For B model 1.7 Vi to 3.0 Vi the limit is 44.8 bar

(650 psia)

– For C model 1.3 to 1.96 Vi the limit is 63.7 bar

(925 psia)

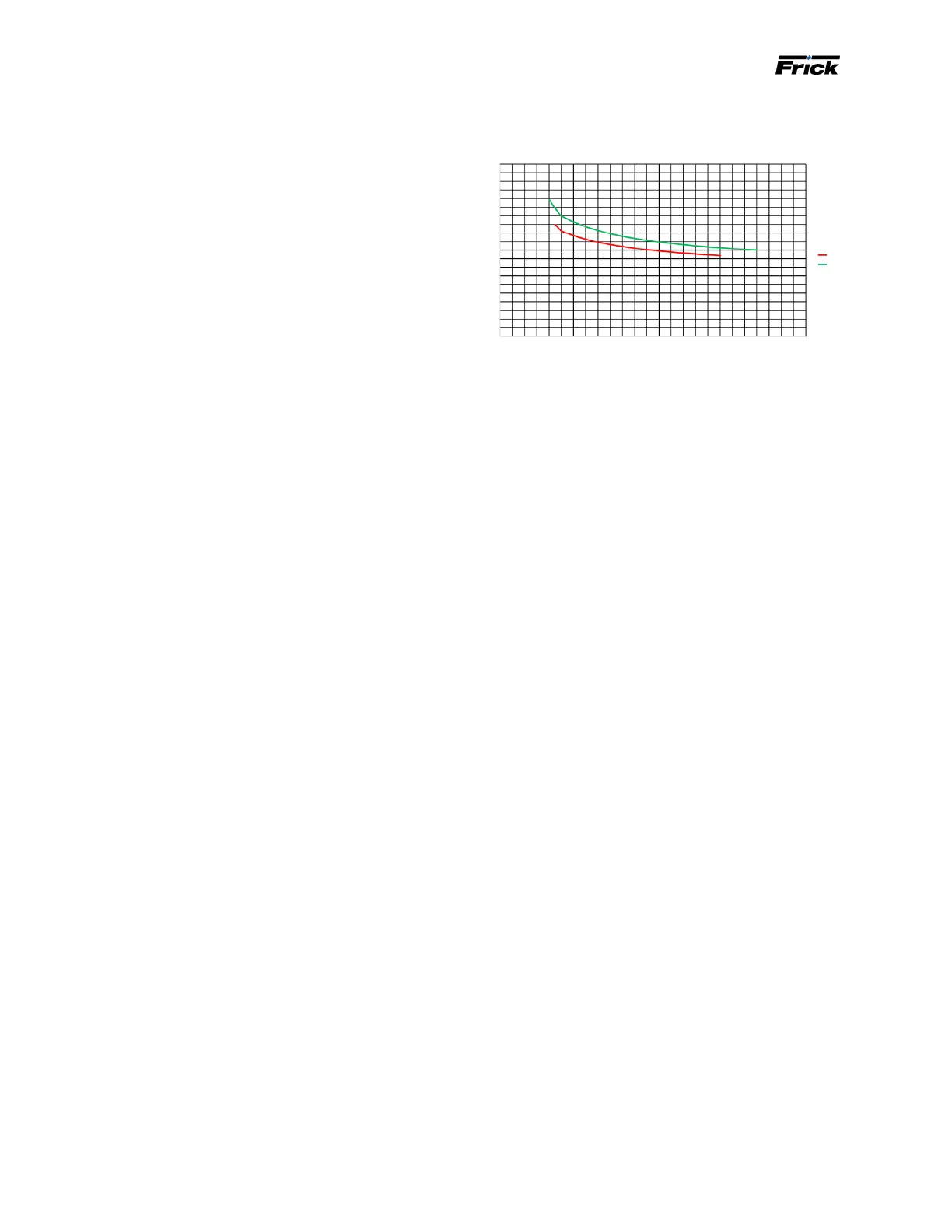

Figure 5: HPS 273 and 407 viscosity requirement as

function of speed

• The maximum discharge temperature for the HPS 273

407 compressor models is limited to 125°C (257°F).

Refer to 160.802-SPC, Compressor Oil Specications

for more detail.

• Screw compressors are oil-ooded machines that use

oil to lubricate bearings, seals, and rotors, and also

to seal clearances in the rotor mesh and control the

compressor’s discharge temperature. Screw compres-

sors however, are designed to compress gases and not

pump liquids, so the amount of oil introduced into the

compressor is regulated. When using variable-speed

motors to drive the compressors, take particular care

to regulate the main oil injection oil ow when slowing

down the driver speed. This is to avoid supplying too

much oil to the compressor, which can result in a failure

due to liquid slugging. If the total oil ow supply to the

compressor is more than 1.5% of the compressor’s

swept volume, and the turndown of the variable-speed

drive is more than 3, the main oil ow must be regulat-

ed. The turndown of a variable-speed drive is dened as

the actual maximum speed of the driver divided by the

actual minimum speed of the driver. CoolWare calculates

the oil ow in Lpm and gpm. See Table 2, Table 3, Table

4, or Table 5 depending on what model you own.

• The UNISAB and Quantum panels have several lay-

ers of control functions to secure reliable operation.

Depending on many operating conditions, they unload

the slide valve and reduce or increase speed to keep

the compressor running in a safe way. Only as a last

resort do they initiate an alarm and ultimately stop the

compressor.

This is particularly true for the HPS 273 and 407

compressor models on applications with high suction

pressure, like fuel gas boosting. The concern is that

the high internal thread pressure may lead to excessive

rotor deection and unwanted contact with the rotor

housing. For this reason,

correct

calibration of the slide

valve and slide stop is essential.

Note: For 1.3 to 1.96 and 1.7 to 3.0 Vi range machines, the

main oil injection occurs at lower Vi port locations

than compressors operating with the 2.2 to 5.0 Vi

range. This means the UNISAB and Quantum use

lower values for the safeties.

Shaft speed, rpm

1000

20

15

10

5

0

0

2000 3000 4000 5000

Viscosity Min., cst

407

273

Loading...

Loading...