070.750-IOM2 (JUN 22)

Page 24

HPS 273 and 407 Rotary Screw Compressor

Maintenance

Troubleshooting the HPS 273 and

407 compressors

Notice

Unless the service technician has been certied by

Johnson Controls–Frick to rebuild our compressors,

troubleshooting the compressor is limited to identi-

fying the probable cause. If a mechanical problem is

suspected, contact Johnson Controls–Frick Service.

Do not attempt to disassemble compressor.

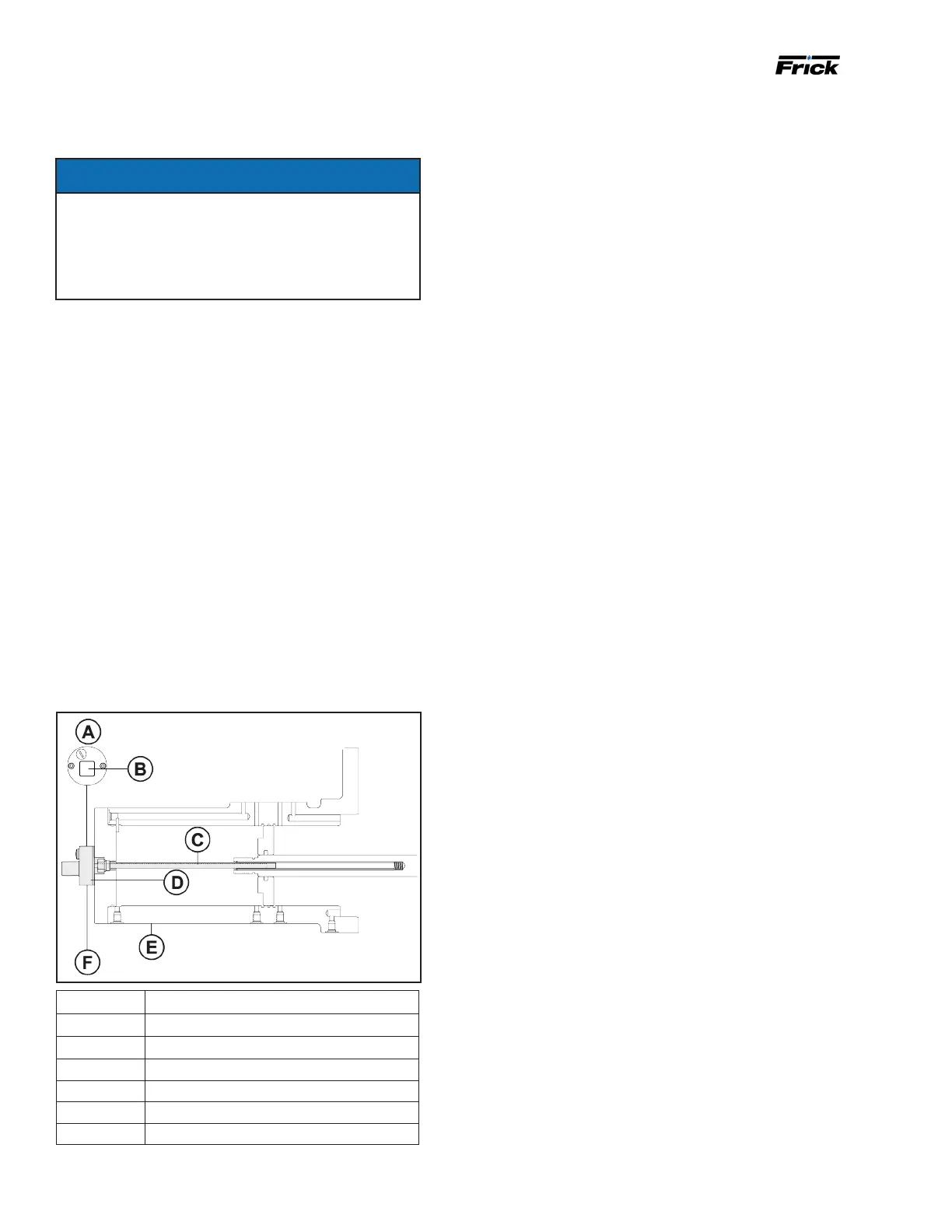

Replacing the capacity linear transmitter: slide

valve

The capacity linear transmitter is located on the end of the

compressor cylinder. See Figure 10. The linear transmit-

ter with hermetic enclosure is based on the inductive

measuring principle. It features removable electronics,

from the sensor well, eliminating the need to evacuate the

compressor for replacement. This type of transmitter is

dedicated to capacity control and is not adjustable.

1. Shut off control power.

2. Remove the DIN connector plug from the transmitter.

3. Loosen the cap screws.

4. Remove the transmitter unit.

5. Install the new transmitter unit.

6. Tighten the cap screws.

7. Apply the DIN connector plug to the transmitter.

8. Turn on control power.

9. Only calibrate using the controller.

Figure 10: Capacity linear transmitter

Callout Description

A End view

B DIN connector

C Stainless steel well

D Heat isolator

E Compressor unload cylinder

F Cast aluminum housing

Note: Shaded area shows capacity linear transmitter.

Replacing a bare compressor

Only complete following procedure when replacing a bare

compressor in the eld:

1. Verify that main power to the unit is disconnected and

tag the switch.

2. Remove all tubing, piping, and wiring that is connects

to the compressor.

3. Disconnect the coupling from the motor shaft.

4. While supporting the motor and compressor assembly

with a crane, remove the bolts at the motor feet, and

then at the compressor feet.

5. Thoroughly clean the compressor and motor feet and

mounting pads of burrs and other foreign matter to

ensure rm seating of the compressor.

6. Thoroughly clean the new compressor and remove all

cover plates and protection.

7. Install new gaskets and sealing in all connections.

8. Set the new compressor in place and shim feet where

required.

9. Reattach the drive coupling.

10. Check the shaft alignment if a factory-provided motor

mount is not used.

11. Complete tubing, piping, and wiring.

Note: Refer to 070.660-SM, Bare Rotary Screw Compres-

sor Replacement when a motor tunnel is installed.

Shutdown due to incorrect oil pressure, high

stage and booster

The compressor must not operate with incorrect oil pres-

sure.

Refer to relevant Control Setup.

Loading...

Loading...