070.750-IOM2 (JUN 22)

Page 11

HPS 273 and 407 Rotary Screw Compressor

Installation

Installation Rigging and handling

You can move the compressor with rigging, using a crane

or forklift, by hooking into the two lifting rings at each end

of the main housings. Only use the compressor lifting rings

to lift the compressor itself.

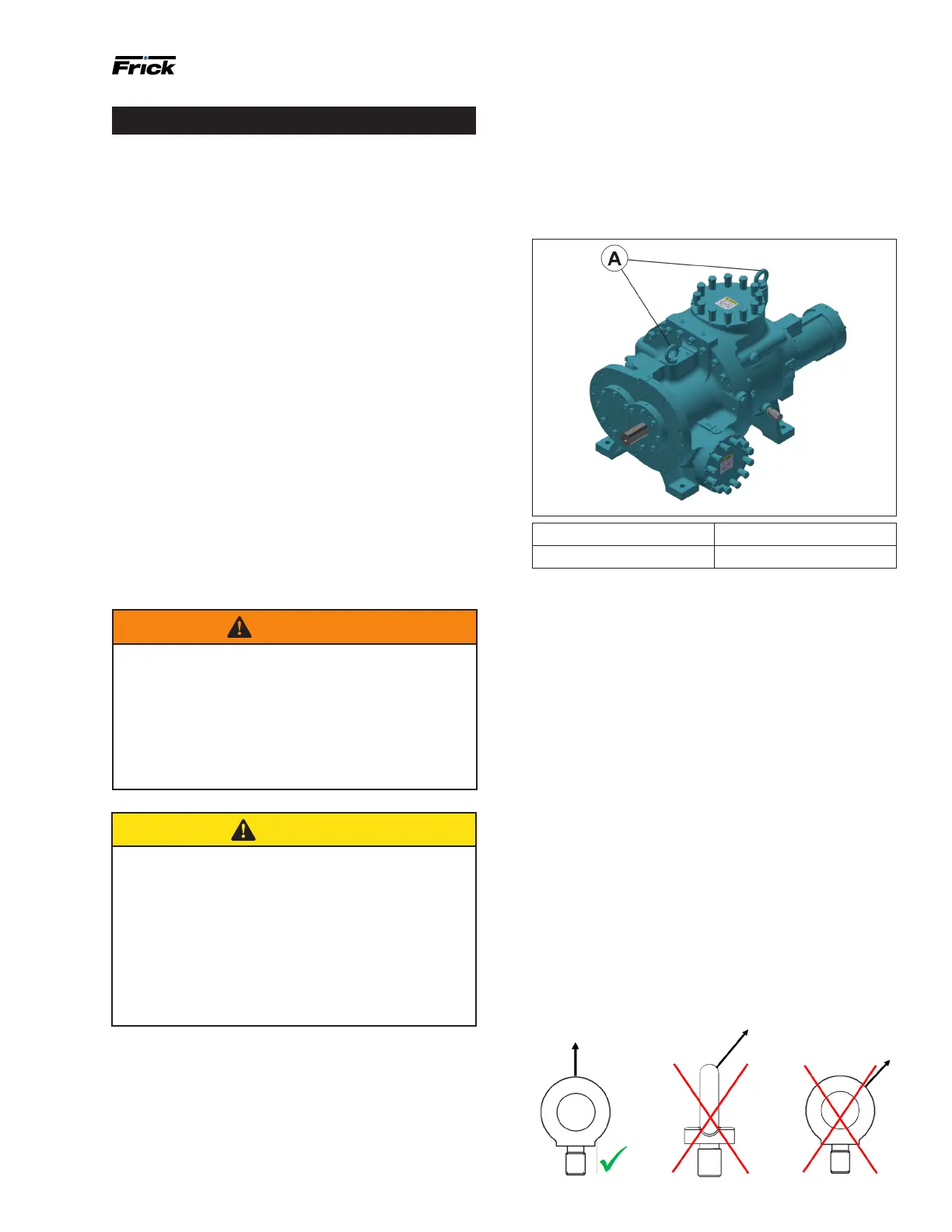

Figure 6: Lifting rings

Callout Component

A Lifting rings

Lifting instructions

Lifting rings are located to facilitate the rigging and lifting

of the bare compressor. See Figure 6. Ensure that only a

qualied operator performs the lifting and that they follow

the necessary precautions.

• Lift rings are intended for lifting the bare compressor

only.

• Examine the lift rings for damage before lifting the

compressor. Replace any damaged rings.

• Fully screw in the lift rings and seat them rmly against

the contact surface before lifting.

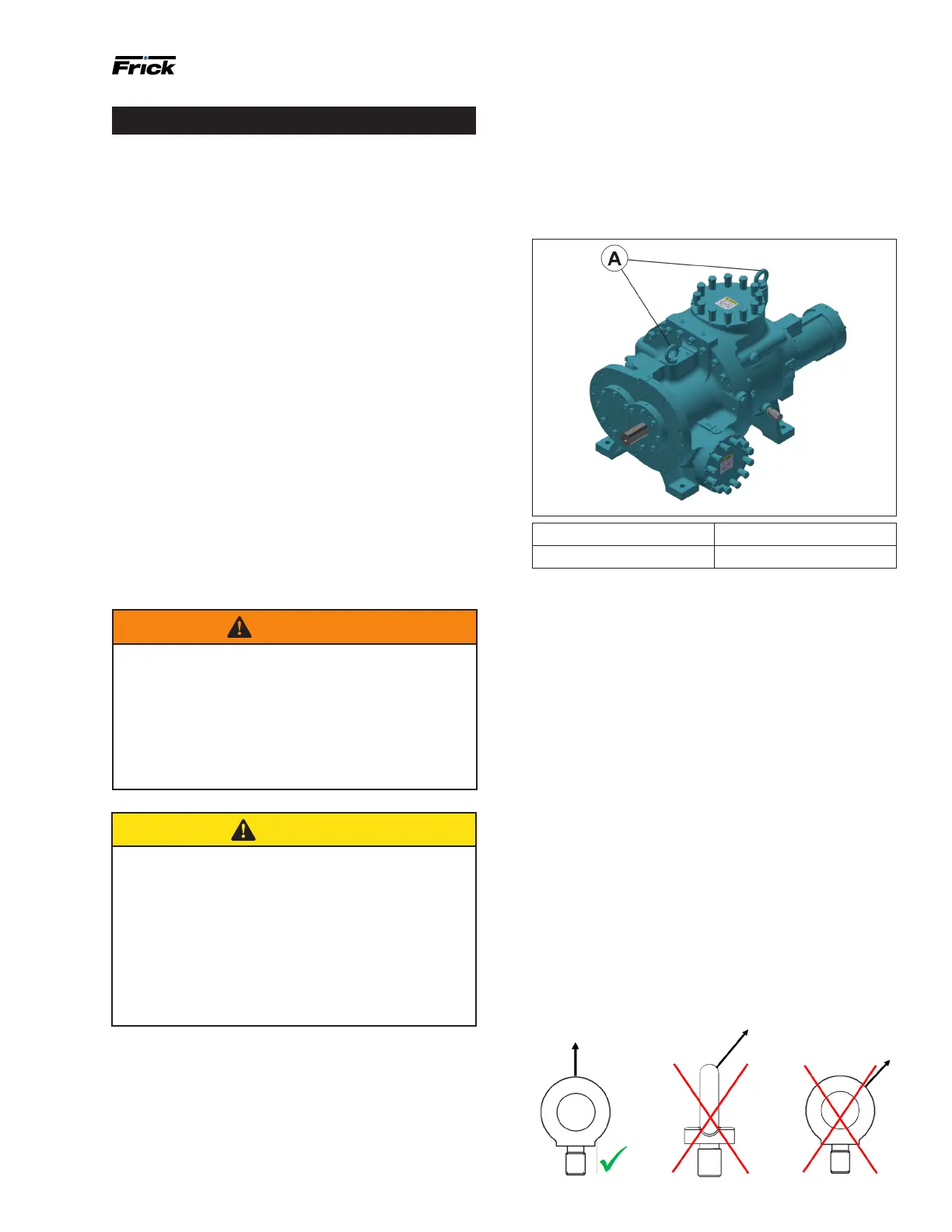

• Load the lift rings in the vertical direction only.

Ensure that the load is parallel to the threaded portion

of the lift ring. See Figure 7. This may require the use

of a spreader beam. Loading the lift rings at an angle

reduces their load capacity.

• Ensure that the load is level and stable before lifting

more than a few inches.

• Lift the compressor slowly.

• Remove the lift rings from the compressor before

operation. The vibration of a running compressor can

cause the lift rings to loosen and become damaged.

Figure 7: Lifting rings orientation

HPS 273 and 407 compressors are designed to be driven

with an open drive, foot-mounted motor. Do not exceed

the rotor and bearing design set limitations: refer to Cool-

Ware for more information. Refer to 090.040-O, Quantum

HD Control Panel for additional information on setpoint

limits.

Outline dimensions

Find complete dimensions and connection information on

the outline drawing, which you can request by contacting

Johnson Controls-Frick Sales. See Figure 11 and Figure 12.

Holding charge and storage

Every HPS 273 and 407 compressor is pressure and leak

tested at the Johnson Controls–Frick factory and thor-

oughly evacuated and charged with dry nitrogen to ensure

its integrity during shipping and short-term storage before

installation.

Keep all compressors in a clean, dry location to prevent

corrosion damage. For compressors stored for more than

two months, check their nitrogen charge periodically.

See General information for complete instructions and

refer to 020.050-W Limited Warranty Screw Compressor

Purchased for Long-Term Storage for FRICK Bare Screw

compressors.

Warning

Holding-charge shipping gauges, if mounted, are

rated for 2.1 bar (30 psig) and are for checking the

shipping charge only. They must be removed before

pressure testing and operating the system. Failure to

remove these gauges may result in catastrophic fail-

ure of the gauge resulting in serious injury or death.

Access valves are bronze and they must be replaced

with steel plugs when package is assembled.

Caution

This equipment has been pressurized with nitrogen

gas. Temporary valves and gauges have been in-

stalled.

1. Relieve pressure before opening lines or making

eld connections.

2. Remove charging valves or gauges be pressurizing

system.

3. Refer to installation operation and maintenance

manual for additional information.

Escaping gas may cause injury.

Loading...

Loading...