070.750-IOM2 (JUN 22)

Page 7

HPS 273 and 407 Rotary Screw Compressor

Installation - Operation - Maintenance

Volumizer variable volume ratio control

Screw compressors do not have regulating valves in the

suction and discharge ports of the compressor body to

regulate the opening and closing of ports. Instead, the

geometry of the rotors and housings define the port open-

ings and closings and subsequently the swept volume of the

compressor.

On the inlet end of the compressor, refrigerant vapor fills

the volume of the rotor threads until the rotor rotates to a

position that closes off the suction port. On the discharge

end of the compressor the same rotor thread opens to the

discharge port in the housing, ideally when the pressure

inside the thread is equal to the outside system pressure.

If the internal thread pressure is higher, over-compression

occurs, and if the internal thread pressure is lower, then

under-compression occurs; in both situations the unit is

inefcient. The pressure inside the threads is affected by

temperature, volume, the presence of a non-compressible

liquid, such as the oil, and leakage due to internal clear-

ances. The ratio of the rotor thread volume at the suction

end divided by the rotor thread volume at the discharge

end is dened as the compressor volume ratio (Vi). Because

the mass ow at the suction port and the mass flow at the

discharge port are the same, you can calculate the vol-

umes at these locations using their respective values of gas

densities.

The Frick compressor includes a method of varying the

internal Vi to match the system pressure ratio. Control of

the internal Vi eliminates the power penalty associated with

over- or under-compression. Vi control is achieved by the

use of a slide stop, a movable portion of the rotor hous-

ing assembly that moves axially with the rotors to control

discharge port location.

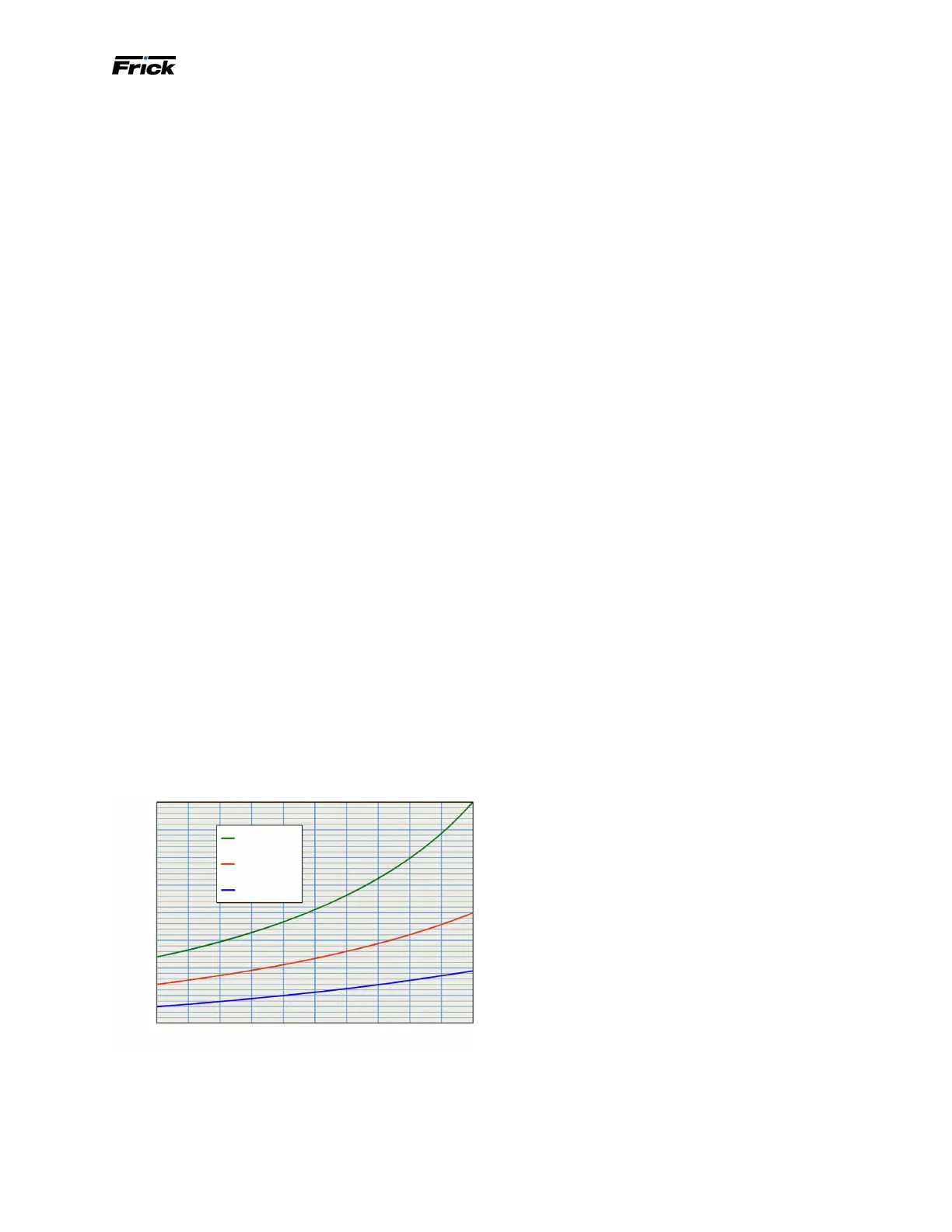

HPS compressors are available in three different Vi ranges;

2.2 to 5.0, 1.7 to 3.0, and 1.3 to 1.96, and the relationship

between the Vi and slide stop position is shown in the fol-

lowing figure:

Figure 4: HPS compressors volume ratio, Vi

Stepless capacity control

Capacity control is achieved by use of a movable slide valve.

The slide valve moves axially under the rotors to provide

fully modulated capacity control from 100% to approxi-

mately 20% minimum load capacity. Approximate minimum

load capacity varies slightly with compressor model, pres-

sure ratio, discharge pressure level, and rotor speed.

The slide valve is positioned by hydraulic movement of its

control piston. When in the unloaded position, gas is by-

passed back to suction through a recirculation slot before

compression begins and any work is expended, providing

the most efcient unloading method available for part-

load operation of a screw compressor.

Oil pump, optional

A demand oil pump is required for low differential pressure

applications.

Note: CoolWare provides a warning when the oil differen-

tial pressure is too low.

Oil being supplied to the compressor from the oil separa-

tor is at the system discharge pressure minus the pressure

drop in the oil system piping, oil lter, and valves. Oil port-

ing to all parts of the compressor is vented back to a loca-

tion in the compressor’s body that is at a lower pressure

than compressor discharge pressure. All oil entering the

compressor is moved by the compressor rotors, out the

compressor outlet, and back to the system oil separator.

Balance piston oil requirements and regulation

When operating, the discharge pressure of a compressor

can force the rotors back towards the suction, creating a

load on the thrust bearing assembly. In cases where the

discharge pressure is high, this axial load can be exces-

sive for the compressor’s thrust bearings and limit their

operating life. To compensate for this situation, a balance

piston assembly is designed to generate a counter force

that reduces the load on the thrust bearings and increases

their operating life.

In a conventional balance piston arrangement, oil pressure

enters the compressor, which is regulated by an outlet

pressure regulating valve and orice. This regulated oil

pressure acts against an internal piston that generates a

force to counter the rotor thrust. The problem is that the

conventional balance piston regulator is set for a specic

operating condition and when the load or operating condi-

tions vary the balance piston pressure may be insufcient.

HPS models use a motorized balance piston regula-

tor controlled by a programmable logic controller (PLC).

The PLC compensates for the changing compressor load

and conditions by continually calculating the oil pres-

sure required to maintain the necessary counter force.

The PLC accomplishes this by monitoring seven different

inputs: compressor Vi, suction pressure, slide valve posi-

tion, economizer pressure, discharge pressure, operating

speed, and oil pressure. It uses these values to identify the

target pressure for the balance piston regulator in a look

up table. The PLC communicates this new target pressure

to the balance piston regulator controller and the valve is

modulated to generate the target oil pressure.

HPS models have balance pistons on the male and female

inlet end of the compressor rotors with oil supplied

through the SB-2 port.

1.00

0% 10% 20% 30% 40% 50% 60% 70% 80% 90% 100%

2.00

3.00

4.00

1.50

2.50

3.50

4.50

5.00

Volume ratio

Vi = 2.2 - 5.0

Vi = 1.7 - 3.0

Vi = 1.3 - 1.96

Slide stop travel (SS), 0% to 100%

Loading...

Loading...