RWF ROTARY SCREW COMPRESSOR UNITS

OPERATION

S70-600 IOM

Page 14

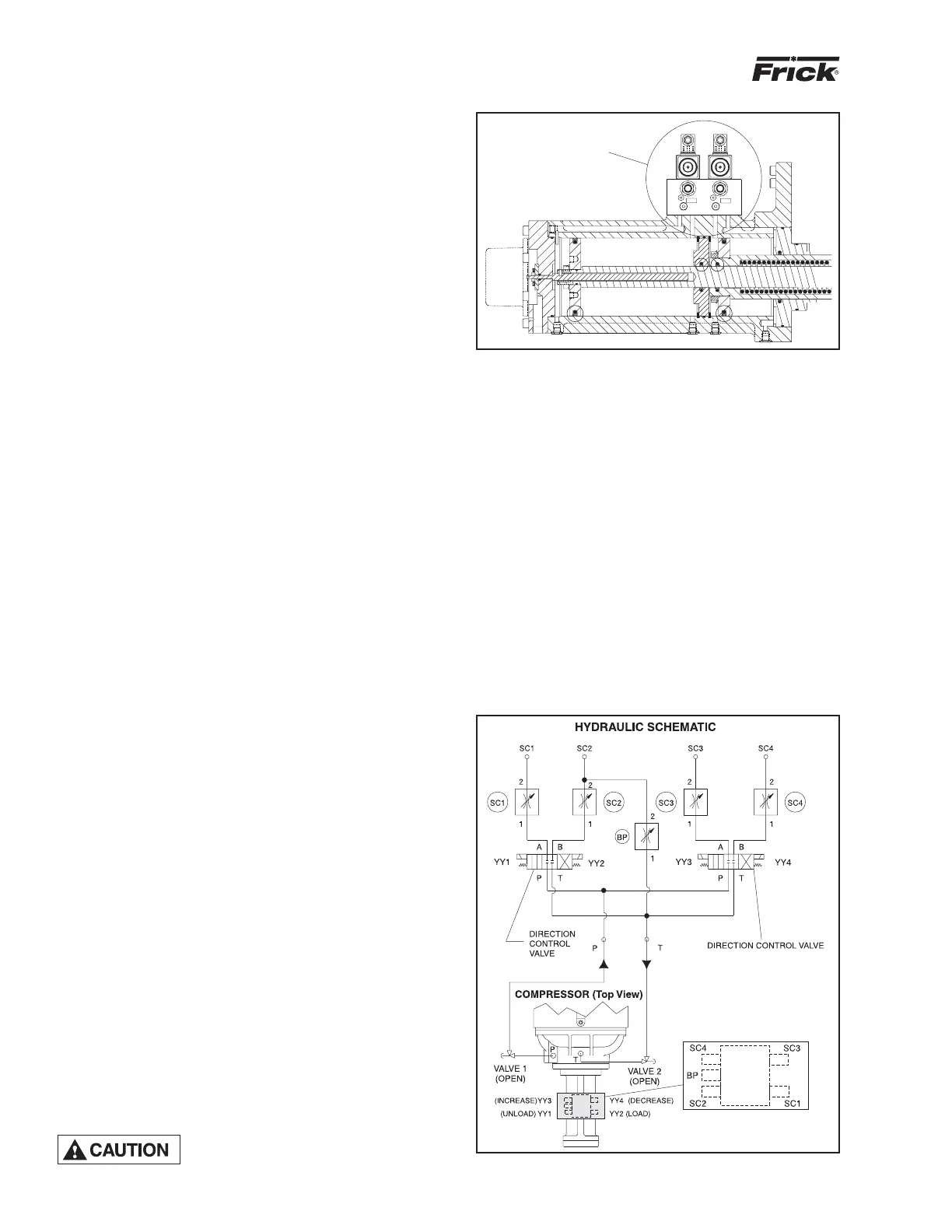

COMPRESSOR HYDRAULIC SYSTEM

The compressor hydraulic system moves the movable slide

valve (MSV) to load and unload the compressor. It also

moves the movable slide stop (MSS) to increase or de-

crease the compressor’s volume ratio (Vi).

The hydraulic cylinder located at the inlet end of the SGC

compressor serves a dual purpose. It is separated by a

fixed bulkhead into two sections. The movable slide valve

(MSV) section is to the left of the bulkhead and the movable

slide stop (MSS) to the right. Both sections are considered

double-acting hydraulic cylinders as oil pressure moves

the pistons in either direction.

Both sections are controlled by double-acting, four-way so-

lenoid valves which are actuated when a signal from the

appropriate microprocessor output energizes the solenoid

valve.

SINGLE-ACTING MODE - High Stage

Open valve at SC1

Close valve at SC2

Open valve at BP (bypass)

High stage compressor loading: The compressor loads

when MSV solenoid YY2 is energized and oil flows from the

unload side of the cylinder out port SC1, through valve

ports A and T to compressor suction. Simultaneously, dis-

charge pressure loads the slide valve.

High stage compressor unloading: The compressor un-

loads when MSV solenoid YY1 is energized and oil flows

from the oil manifold through valve ports P and A to cylinder

port SC1 and enters the unload side of the cylinder. Simul-

taneously, gas on the load side of the cylinder is vented

through port SC2 and valve BP to compressor suction.

NOTE: To control the rate of loading and unloading,

throttle the needle valve at SC1 port.

DOUBLE-ACTING MODE - Booster

Open valve at SC1

Open valve at SC2

Close valve at BP (bypass)

Booster Compressor Loading: The compressor loads

when MSV solenoid YY2 is energized and oil flows from the

oil manifold through valve ports P and B to cylinder port

SC2 and enters the load side of the cylinder. Simultaneously,

oil contained in the unload side of the cylinder flows out

cylinder port SC1 through valve ports A and T to compressor

suction.

Booster Compressor Unloading: The compressor unloads

when MSV solenoid YY1 is energized and oil flows from the

oil manifold through valve ports P and A to cylinder port

SC1 and enters the unload side of the cylinder.

Simultaneously, oil contained in the load side of the cylin-

der flows out of compressor port SC2 through valve ports B

and T to compressor suction.

NOTE: To control the rate of loading and unloading,

throttle valves SC1 and SC2.

NOTE: To slow all valve movements - loading, unloading,

and Vi change - throttle valve 2.

NEVER open valve BP and valve

SC2 at the same time during com-

pressor operation.

Figure 15

VOLUMIZER VOLUME RATIO CONTROL

Open valve at SC3

Open valve at SC4

Compressor Vi increase: The volume ratio Vi is increased

when MSS solenoid valve YY3 is energized and oil flows

from the oil manifold through valve ports P and A to com-

pressor port SC3, enters the increase side of the cylinder

and overcomes the decrease spring tension. Simulta-

neously, oil flows from SC4 port through valve ports B and T

to compressor suction.

Compressor Vi decrease: The volume ration Vi is de-

creased when MSS solenoid valve YY4 is energized and

oil flows from the oil manifold through valve ports P and B to

compressor port SC4, enters the decrease side of the cylin-

der. Simultaneously, oil flows form SC3 port through valve

ports A and T to compressor suction.

TO CONTROL THE RATE OF VI CHANGE, THROTTLE THE

NEEDLE VALVE AT SC3 PORT.

SC1

SC3

SEE HYDRAULIC

SCHEMATIC

FOR FUNCTIONAL

VIEW OF VALVE

OPERATION

Figure 16

Loading...

Loading...