RWF ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

S70-600 IOM

Page 7

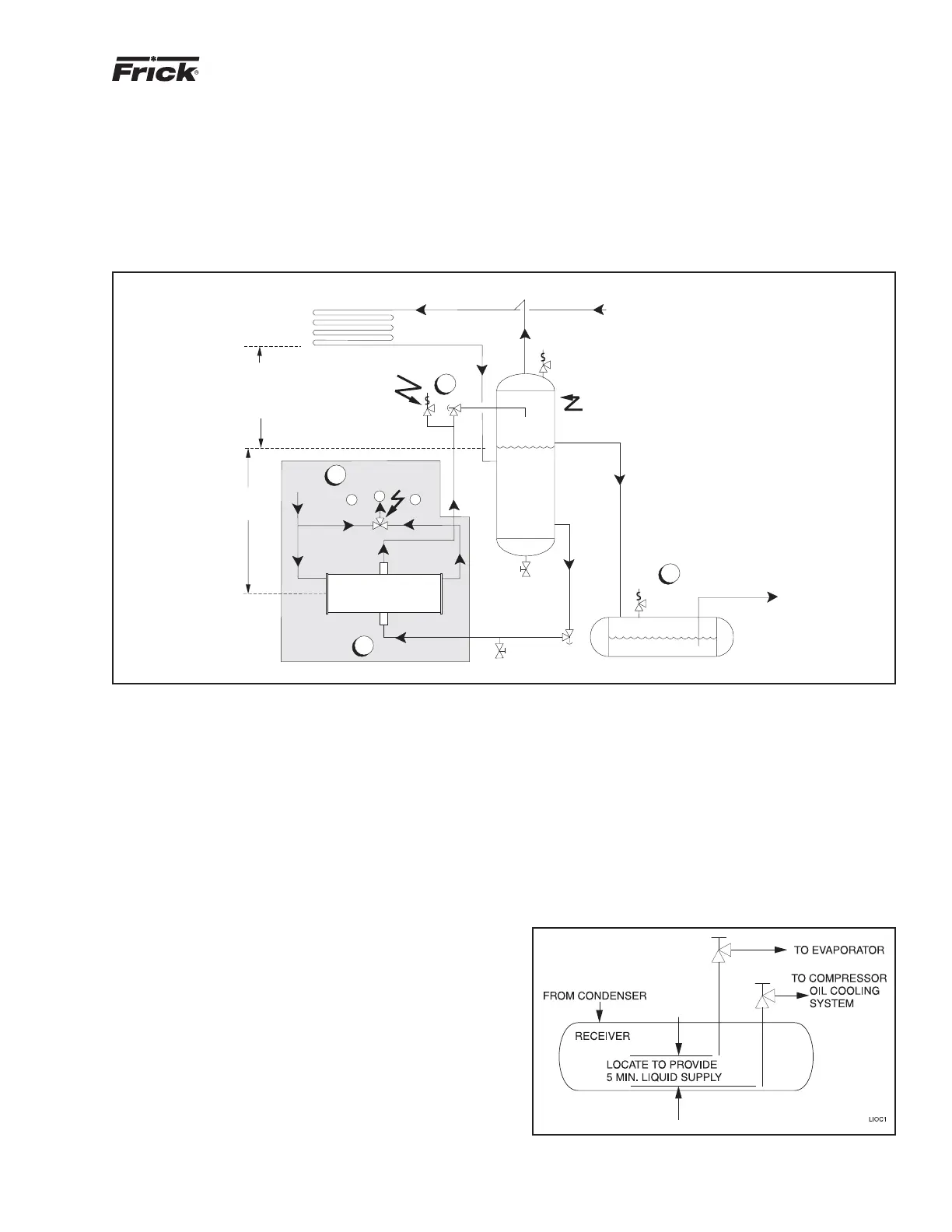

B

C

A

OPT. OIL TEMP

CONTROL VALVE

HOT

REFRIGERANT

OUT

REFRIGERANT IN

COOL

COOL

OIL OUT

HOT OIL IN

LIQUID

LEVEL

STATIC HEAD

TO OVERCOME

CONDENSER

PRESSURE DROP

6 Ft.

Min.

SYSTEM

CONDENSER

SAFETY

VALVE

VAPOR

THERMOSYPHON

RECEIVER

LIQUID OVERFLOW

DRAIN TO RECEIVER

TO SYSTEM

EVAPORATOR

SYSTEM

RECEIVER

1

3

4

(Mounted below Thermosyphon

receiver level)

2

PLATE COOLER

TSOC

Figure 3

1. The thermosyphon oil cooler is supplied with the oil side piped to the compressor unit and stub ends supplied on the refrigerant side.

2. A three-way oil temperature control valve is required where condensing temperature is expected to go below 65°F.

3. A refrigerant-side safety valve is required in this location only when refrigerant isolation valves are installed between the cooler and

thermosyphon receiver. If no valves are used between the cooler and TSOC receiver, the safety valve on the TSOC receiver must be sized

to handle the volume of both vessels. Then, the safety valve on the cooler vent (liquid refrigerant side) can be eliminated.

4. The system receiver must be below the thermosyphon receiver in this arrangement.

LIQUID INJECTION OIL COOLING (Optional)

The liquid injection system provided on the unit is self-con-

tained but requires the connection of the liquid line sized as

shown in the table and careful insertion of the expansion valve

bulb into the thermowell provided in the separator. High pres-

sure gas is connected through the regulator to the external

port on the liquid injection valve to control oil temperature.

NOTE: For booster applications the high pressure gas

connection must be taken from a high side source (high

stage compressor discharge). This should be a 3/8" line

connected into the solenoid valve provided. This gas is

required by the expansion valve external port to control

oil temperature.

It is IMPERATIVE that an uninterrupted supply of high pres-

sure liquid refrigerant be provided to the injection system at

all times. Two items of EXTREME IMPORTANCE are the

design of the receiver/liquid injection supply and the size of

the liquid line.

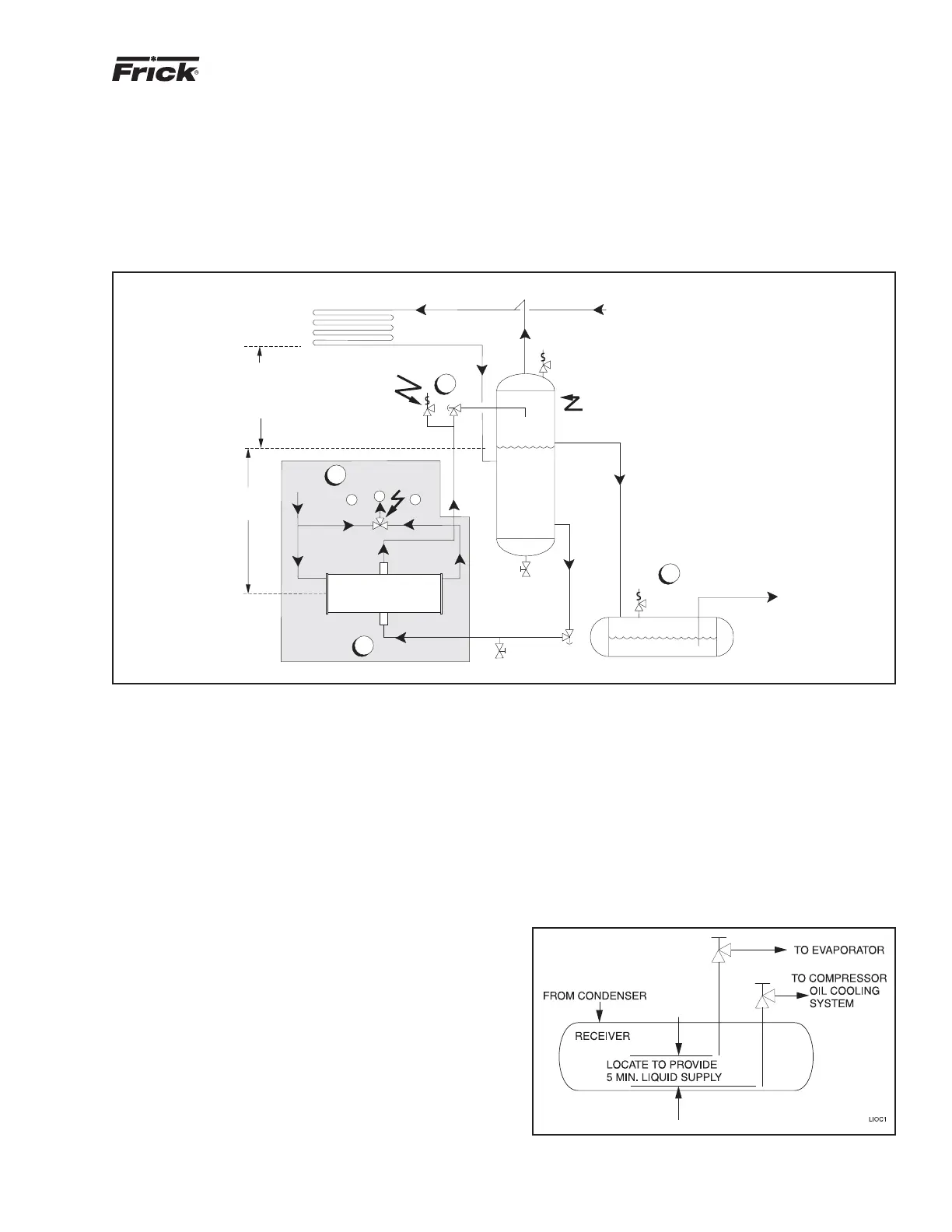

It is recommended that the receiver be oversized sufficient-

ly to retain a 5-minute supply of refrigerant for oil cooling.

INSTALLATION - The plate and shell type thermosyphon

oil cooler with oil-side piping and a thermostatically con-

trolled mixing valve (if ordered) are factory mounted and

piped. The customer must supply and install all piping and

equipment located outside of the shaded area on the piping

diagram with consideration given to the following:

1. The refrigerant source, thermosyphon or system receiv-

er, should be in close proximity to the unit to minimize pip-

ing pressure drop.

The evaporator supply must be secondary to this consider-

ation. Two methods of accomplishing this are shown.

The dual dip tube method (Figure 4) uses two dip tubes in

the receiver. The liquid injection tube is below the evaporator

tube to ensure continued oil cooling when the receiver level

is low.

Figure 4

2. The liquid level in the refrigerant source must be 6 to 8

feet minimum above the center of the oil cooler.

3. A safety valve should be installed if refrigerant isolation

valves are used for the oil cooler.

The component and piping arrangement shown in Figure 3 is

intended only to illustrate the operating principles of thermo-

syphon oil cooling. Other component layouts may be better

suited to a specific installation. Refer to publication E70-900E

for additional information on Thermosyphon Oil Cooling.

Loading...

Loading...