RWF ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

S70-600 IOM

Page 6

OIL CHARGE

The normal charging level is

midway in the top sight glass lo-

cated midway along the oil sepa-

rator shell. Normal operating level

is midway between the top sight

glass and bottom sight glass. The

table gives the approximate oil

charge quantity.

* Includes total in oil separator and

piping. Add 5 gal. for oil cooler.

Add oil by attaching the end of a suitable pressure type hose

to the oil charging valve, located on the top of the oil sepa-

rator between the compressor and motor. Using a pressure-

type pump and the recommended Frick oil, open the charg-

ing valve and pump oil into the separator. NOTE: Fill slowly

because oil will fill up in the separator faster than it

shows in the sight glass.

Oil distillers and similar equipment which act to trap oil must

be filled prior to unit operation to normal design outlet lev-

els. The same pump used to charge the unit may be used

for filling these auxiliary oil reservoirs.

NOTE: The sight glass located in the coalescing end of

the separator near the discharge connection should re-

main empty.

OIL HEATER(S)

Standard units are equipped with two or three 500 watt oil

heaters, providing sufficient heat to maintain the oil tem-

perature for most indoor applications during shutdown cycles

to permit safe start-up. Should additional heating capacity

be required because of low ambient temperature, contact

Frick. The heaters are energized only when the unit is not in

operation.

DO NOT ENERGIZE THE HEATERS

when there is no oil in the unit, the

heaters will burn out. The oil heat-

ers will be energized whenever 120 volt control power is

applied to the unit and the compressor is not running,

unless the 16 amp circuit breaker in the micro enclo-

sure is turned off.

OIL FILTER(S)

Use of filter elements other than

Frick must be approved in writing

by Frick engineering or warranty

claim may be denied.

The oil filter(s) and coalescer filter element(s) shipped with

the unit are best suited to ensure proper filtration and op-

eration of the system.

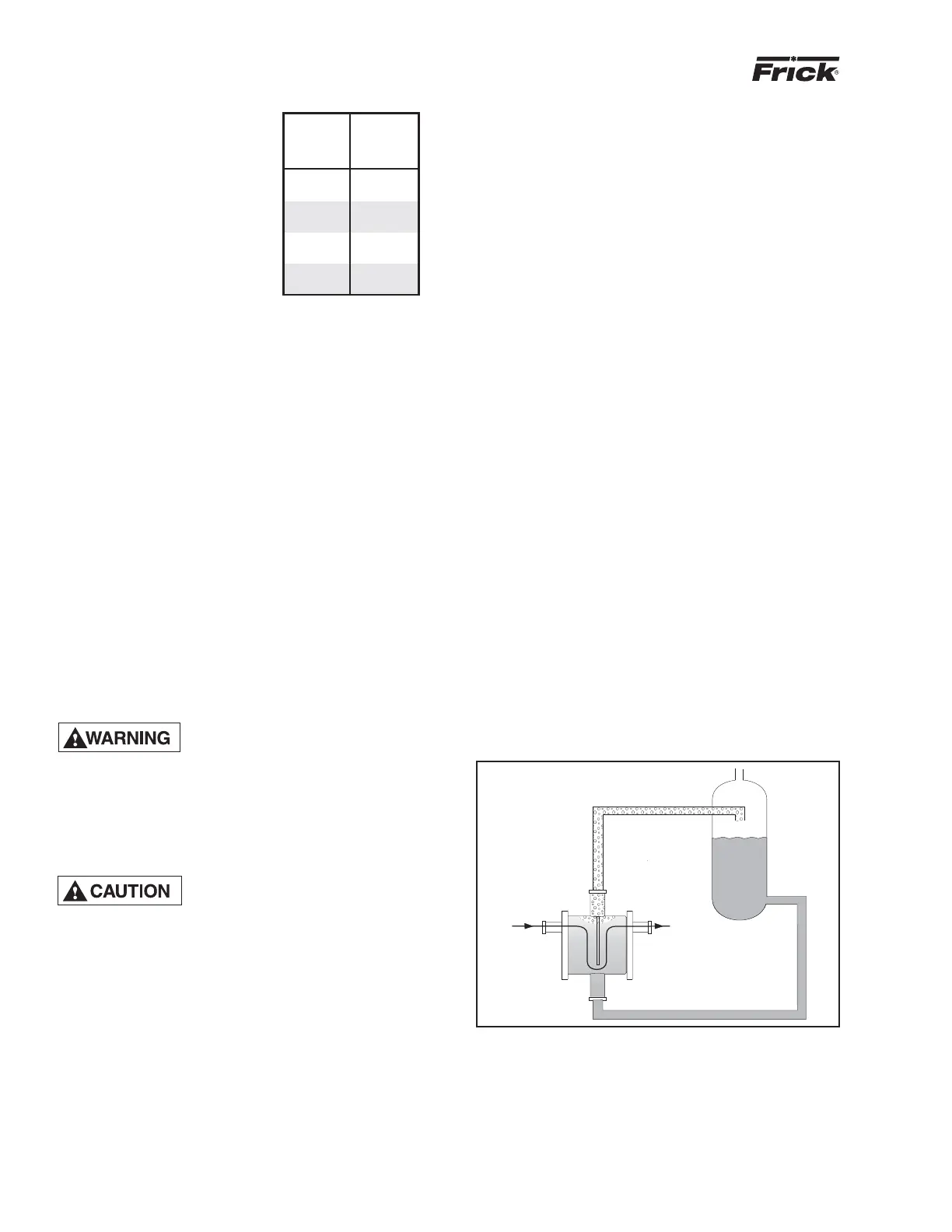

THERMOSYPHON OIL COOLING

Thermosyphon oil cooling is an economical, effective

method for cooling oil on screw compressor units. Ther-

mosyphon cooling utilizes liquid refrigerant at condenser

pressure and temperature that is partially vaporized at the

condenser temperature in a plate and shell vessel, cooling

the oil to within 15°F of that temperature. The vapor, at con-

densing pressure, is vented to the condenser inlet and

reliquified. This method is the most cost effective of all cur-

rently applied cooling systems since no compressor ca-

pacity is lost or compressor power penalties incurred. The

vapor from the cooler need only be condensed, not com-

pressed. Refrigerant flow to the cooler is automatic, driven

by the thermosyphon principle and cooling flow increases

as the oil inlet temperature rises.

EQUIPMENT - The basic equipment required for a ther-

mosyphon system consists of:

1. A source of liquid refrigerant at condensing pressure and

temperature, located in close proximity to the unit to mini-

mize piping pressure drop. The liquid level in the refrigerant

source must be 6 to 8 feet minimum above the center of the

oil cooler.

2. A plate and shell oil cooler with:

Plate Side: Oil 400 lb design

Shell Side: Refrigerant 400 lb design

Due to the many variations in refrigeration system design

and physical layout, several systems for assuring the above

criteria are possible.

SYSTEM OPERATION - Liquid refrigerant fills the cooler

shell side up to the Thermosyphon receiver liquid level.

Hot oil (above the liquid temperature) flowing through the

cooler will cause some of the refrigerant to boil and vapor-

ize. The vapor rises in the return line. The density of the

refrigerant liquid/vapor mixture in the return line is consider-

ably less than the density of the liquid in the supply line.

This imbalance provides a differential pressure that sustains

a flow condition to the oil cooler. This relationship involves:

1. Liquid height above the cooler.

2. Oil heat of rejection.

3. Cooler size and piping pressure drops.

Current thermosyphon systems are using two-pass oil cool-

ers and flow rates based on 3:1 overfeed.

The liquid/vapor returned from the cooler is separated in the re-

ceiver. The vapor is vented to the condenser inlet and need only be

reliquified since it is still at condenser pressure. See Figure 2.

100 50

134 50

177 95

222 95

270 140

316 140

399 140

480 140

BASIC*

CHARGE

(gal.)

RWF

MODEL

NO.

Figure 2

OIL TEMPERATURE CONTROL - Oil temperature will gen-

erally run about 15 - 35°F above condensing temperature.

In many cases, an oil temperature control is not required if

condensing temperature is above 65°F as oil temperature

can be allowed to float with condenser temperature.

Condensing Temperature: 65°F - 105°F

Oil Temperature: 80°F - 140°F

HOT OIL IN

FROM

SEPARATOR

120-140 F

OIL OUT

O

TO SYSTEM CONDENSER

95 F

2.5#/FT

O

3

95 F

36#/FT

O

3

TS RECEIVER

Loading...

Loading...