RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM

Page 33

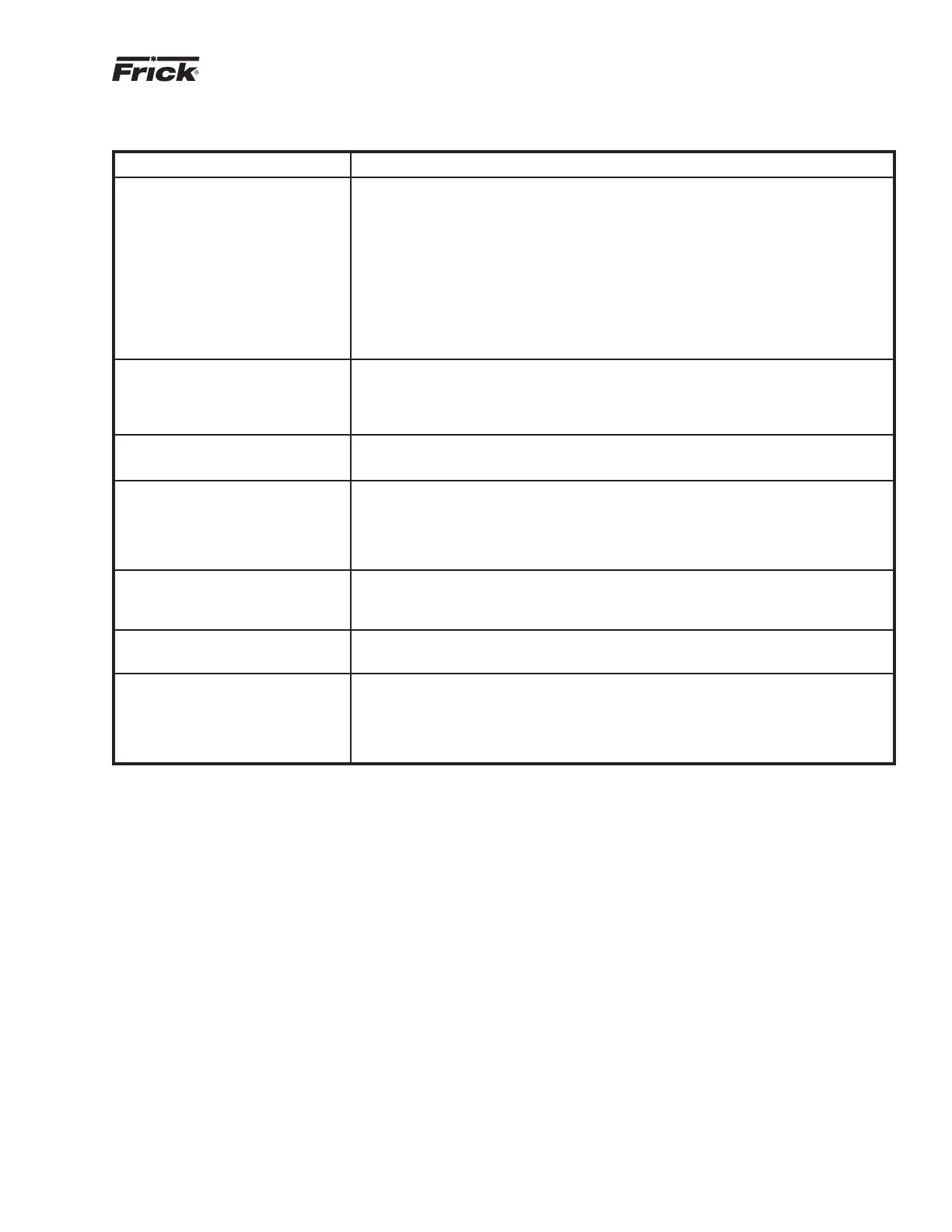

TROUBLESHOOTING THE DEMAND PUMP SYSTEM

SYMPTOM PROBABLE CAUSES and CORRECTIONS

PUMP WILL NOT PRODUCE Check pump rotation.

ENOUGH OIL PRESSURE

TO START COMPRESSOR Check that service valves are open.

Filter cartridges may be blocked. Check PSID across filters.

Strainer may be blocked. Clean.

Oil pressure regulator set too low or stuck open. Readjust or repair.

Pump worn out. Repair or replace.

OIL PRESSURE RAPIDLY DROPS Main oil injection throttling valve too wide open or oil pressure

OFF WHEN COMPRESSOR STARTS regulating valve improperly adjusted. Readjust both valves.

RESULTS IN COMPRESSOR

DIFFERENTIAL ALARM

OIL PRESSURE FLUCTUATES Liquid injection overfeeding or refrigerant flood back from system. Make

necessary adjustments or corrections

NOISE and VIBRATION Pump strainer blocked. Clean.

Liquid refrigerant overfeed. Adjust liquid injection.

Pump worn out. Repair or replace.

GREASE LEAKS FROM VENT PORT Normal leakage which will cease after initial operation. Black oil leaking

IN THE SIDE OF THE PUMP BODY from this vent indicates oil seal wear or failure. If leakage exceeds normal

allowable rate of 7 drops per minute, replace seal.

OIL PRESSURE DROPS AS HEAD Normal behavior. Set main oil injection and oil pressure for maximum head

PRESSURE INCREASES pressure condition.

MAIN FILTER PSID IS TOO HIGH Filters clogged with dirt. Replace.

Oil is too cold. Allow oil to warm up and check again.

Service valve on filter outlet is partially closed. Open valves fully.

Loading...

Loading...