RWF ROTARY SCREW COMPRESSOR UNITS

INSTALLATION

S70-600 IOM

Page 5

CHECKING MOTOR/COMPRESSOR ROTATION

Make sure coupling hubs are tight-

ened to the shaft before rotating the

motor to prevent them from flying

off and possibly causing serious injury or death.

Injury may occur if loose clothing,

etc, becomes entangled on the spin-

ning motor shaft.

COMPRESSOR ROTATION IS CLOCKWISE WHEN FAC-

ING THE END OF THE COM-

PRESSOR SHAFT. Under NO

conditions should the motor ro-

tation be checked with the cou-

pling center installed as dam-

age to the compressor may re-

sult. Bump the motor to check

for correct compressor rotation.

After verification, install disk

drive spacer, as applicable.

COMPRESSOR/MOTOR COUPLING

INSTALLATION

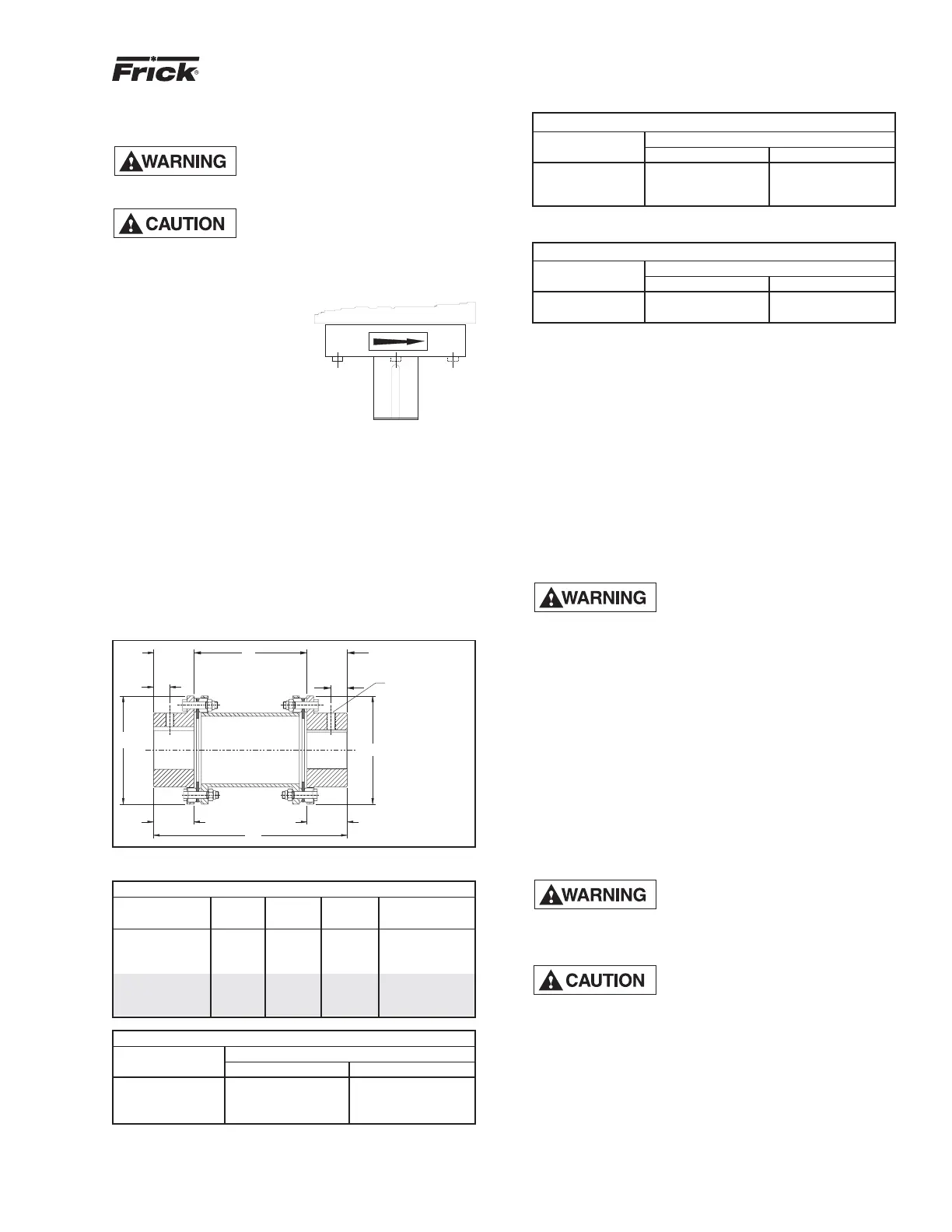

The RWF unit has compressor to motor alignment through

the use of a machined cast iron tunnel. This tunnel is factory

set through machining tolerances ensuring motor compres-

sor alignment. No alignment is required in the field. For

replacement motors, the shaft alignment should be checked

and tolerances verified with the Frick service department.

See Figure 1.

1/2-20UNF

SET SCREW

LOCATE ONE OVER

KEYWAY AND ONE AT

90 FROM KEYWAY

O

12

2 1/2

MIN

2 1/2

MIN

HUB LENGTH HUB LENGTH

7

BETWEEN

SHAFTS

2.50

MIN

2.75

MAX

SHAFT

ENGAGEMENT

2.50

MIN

2.75

MAX

SHAFT

ENGAGEMENT

6.62 ø

6.62 ø

1

1

Figure 1

TORSIONAL DATA

COUPLING MOTOR WEIGHT INERTIA TORSIONAL

PART NO. HUB (lb) lb x in.

2

in. x lb/RADIAN

720C0044H01 2.377 32.4 152 2.89 x 10

6

720C0044H02 2.127 33.1 153 2.89 x 10

6

720C0044H03 1.877 33.8 154 2.89 x 10

6

720C0045H01 2.377 52.6 334 4.58 x 10

6

720C0045H02 2.127 53.5 335 4.33 x 10

6

720C0045H03 2.877 50.7 330 5.06 x 10

6

OPERATING DATA - 60 Hz

SPECIFICATION COUPLING PART NO.

(Maximum) 720C0044H0_ 720C0045H0_

Power (hp) 424 740

Speed (rpm) 3,600 3,600

Torque* (in.-lb) 11,130 19,425

*Includes 1.5 service factor.

ALTERNATE OPERATING DATA - 50 Hz

COUPLING PART NO.

SPECIFICATION 720C0044H0_ 720C0045H0_

Power (hp) 424 740

Speed (rpm) 3,000 3,000

Torque* (in.-lb) 13,356 23,310

*Includes 1.5 service factor.

COUPLING TORQUE RATINGS

COUPLING PART NO.

TORQUE 720C0044H0_ 720C0045H0_

Max continuous 17,500 in.-lb 24,300 in.-lb

Peak overload 35,000 in.-lb 48,600 in.-lb

OIL PUMP COUPLING

Compressor units with direct motor/pump coupled pumps

need no pump/motor coupling alignment since this is main-

tained by the close-coupled arrangement.

HOLDING CHARGE AND STORAGE

Each RWF compressor unit is pressure and leak tested at

the Frick factory and then thoroughly evacuated and charged

with dry nitrogen to ensure the integrity of the unit during

shipping and short term storage prior to installation.

NOTE: Care must be taken when entering the unit to

ensure that the nitrogen charge is safely released.

Holding-charge shipping gauges

on separator and external oil cooler

are rated for 30 PSIG and are for

checking the shipping charge only. They must be re-

moved before pressure testing the system and before

charging the system with refrigerant. Failure to remove

these gauges may result in catastrophic failure of the

gauge and uncontrolled release of refrigerant resulting

in serious injury or death.

All units must be kept in a clean, dry location to prevent

corrosion damage. Reasonable consideration must be given

to proper care for the solid state components of the micro-

processor.

Units which will be stored for more than two months must

have the nitrogen charge checked periodically.

COMPRESSOR UNIT OIL

DO NOT MIX OILS of different

brands, manufacturers, or types.

Mixing of oils may cause excessive

oil foaming, nuisance oil level cutouts, oil pressure loss,

gas or oil leakage and catastrophic compressor failure.

Use of oils other than Frick Oil must

be approved in writing by Frick en-

gineering or warranty claim may be

denied.

The oil charge shipped with the unit is the best suited lubri-

cant for the conditions specified at the time of purchase. If

there is any doubt due to the refrigerant, operating pres-

sures, or temperatures; refer to Frick Pub. E160-802 SPC

for guidance.

MPRE

R

Loading...

Loading...