RWF ROTARY SCREW COMPRESSOR UNITS

MAINTENANCE

S70-600 IOM

Page 34

THERMAL EXPANSION VALVES

In situations where system load conditions increase or de-

crease over extended periods of time and the liquid injec-

tion thermal expansion valve is not adequate for the new

conditions, an improvement in valve performance may be

achieved by increasing or decreasing discharge tube size.

NOTE: DO NOT ATTEMPT TO ADJUST SUPERHEAT

ADJUSTMENT STEM ON BOTTOM OF VALVE IN AN EF-

FORT TO CHANGE THE VALVE’S PERFORMANCE. THIS

ADJUSTMENT IS PRESET AT THE FACTORY. ONLY AD-

JUST 1/4" BLEED VALVE ON EQUALIZING LINE.

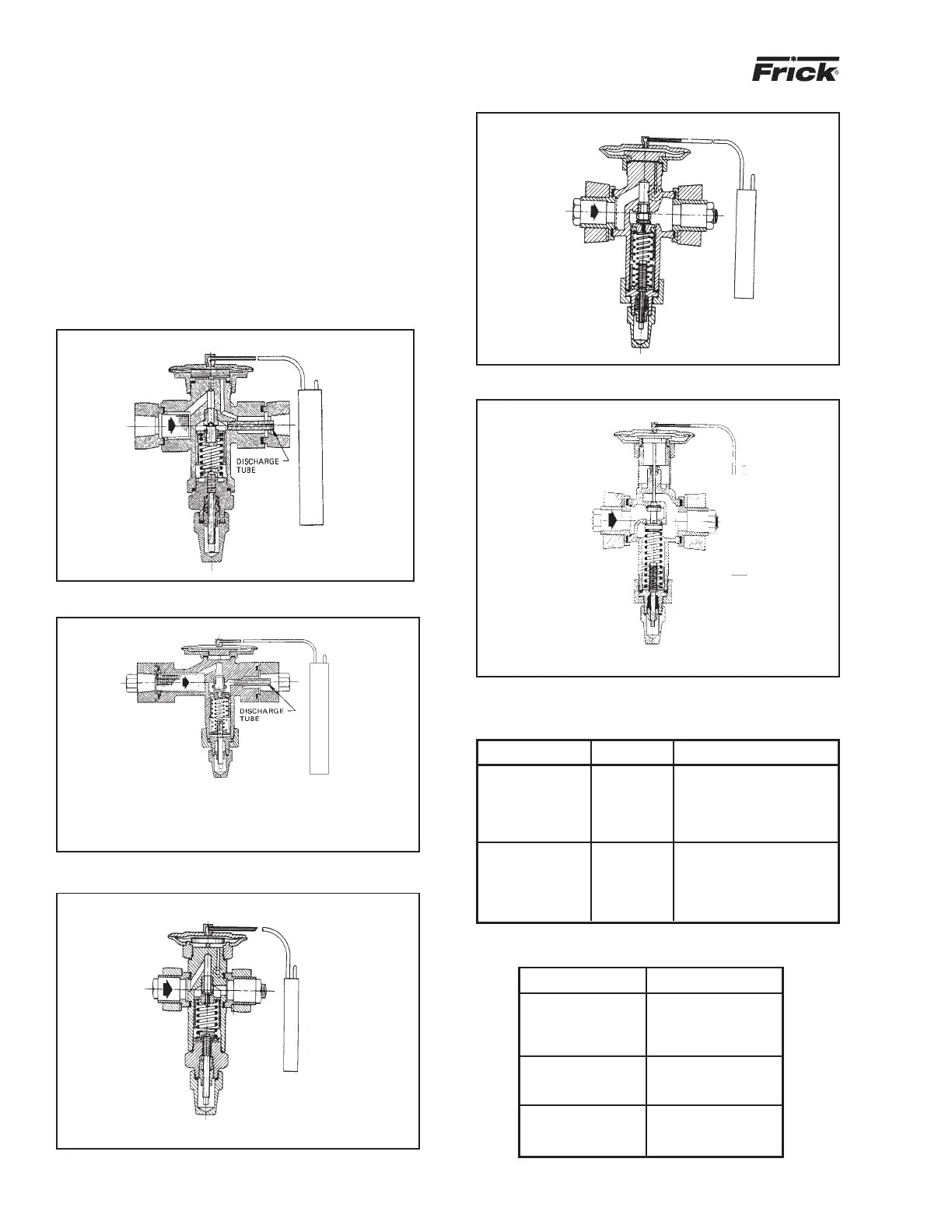

Figure 28 - TYPE D (1-15 TONS) R-717

Figure 29 - TYPE A (20-100 TONS) R-717

Figure 30 - TYPE H (2-1/2 TO 16 TONS) R-22

TX VALVE MODE PORT SIZE DISCHARGE TUBE SIZE

DAE - 1 1/16 1/32

DAE - 2 1/16 1/16

DAE - 5 7/64 5/64

DAE - 10 3/16 7/64

DAE - 15 3/16 5/32

AAE - 20 5/16 1/8

AAE - 30 5/16 5/32

AAE - 50 3/8 3/16

AAE - 75 3/8 NONE

AAE - 100 7/16 NONE

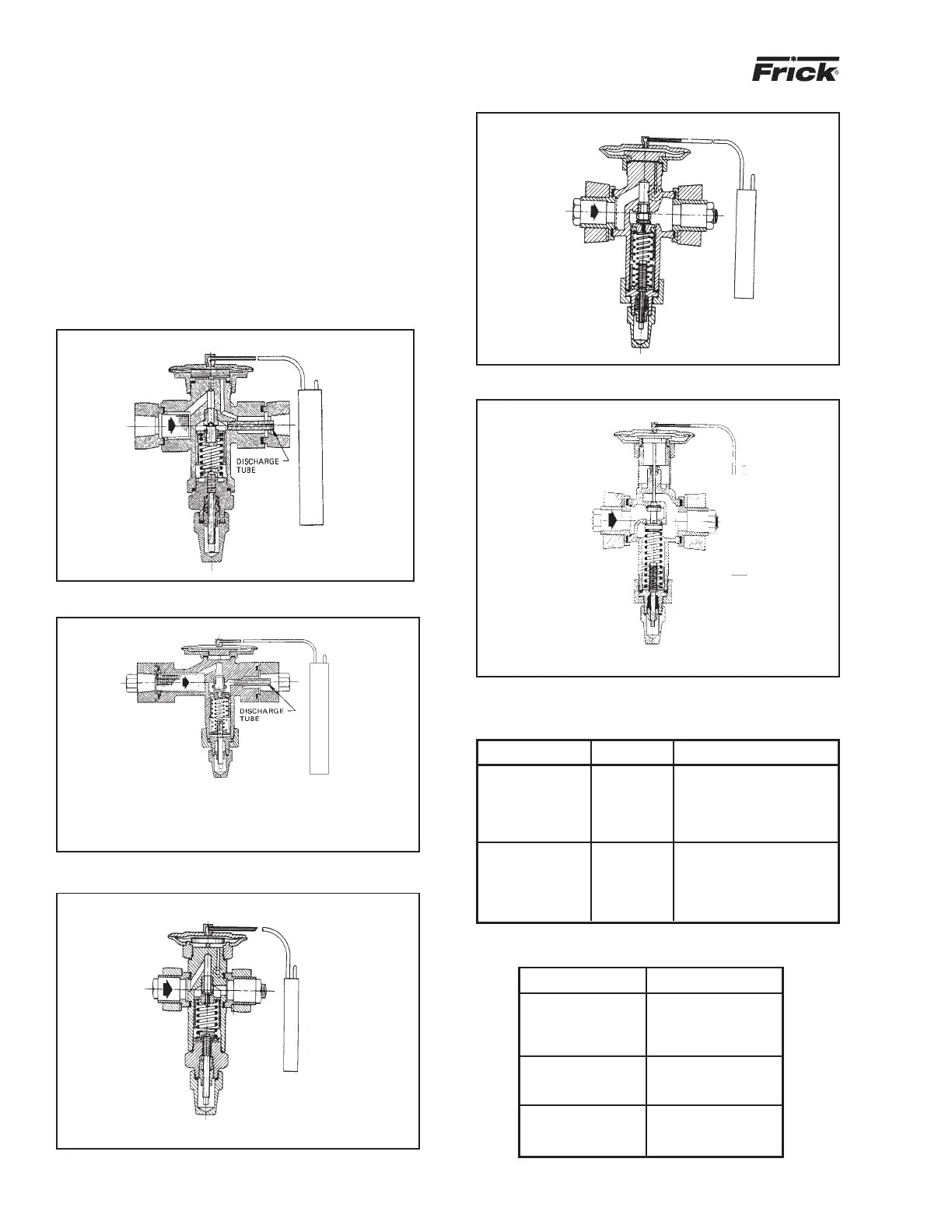

Figure 31 - TYPE M (12 TO 34 TONS) R-22

Figure 32 - TYPE V (52 TO 100 TONS) R-22

R-717 TX VALVE SIZES

R-22 TX VALVE SIZES

TX VALVE MODE FPT CONNECTION

HVE - 2-/1/2 1/2

HVE - 5-1/2 1/2

HVE - 11 1/2

HVE - 16 1/2

MVE - 12 1

MVE - 21 1

MVE - 34 1

VVE - 52 1

VVE - 70 1

VVE - 100 1

Loading...

Loading...